RAGAN Based Feedforward-feedback Multi-step Correction of Operational Indices for Industrial Processes

-

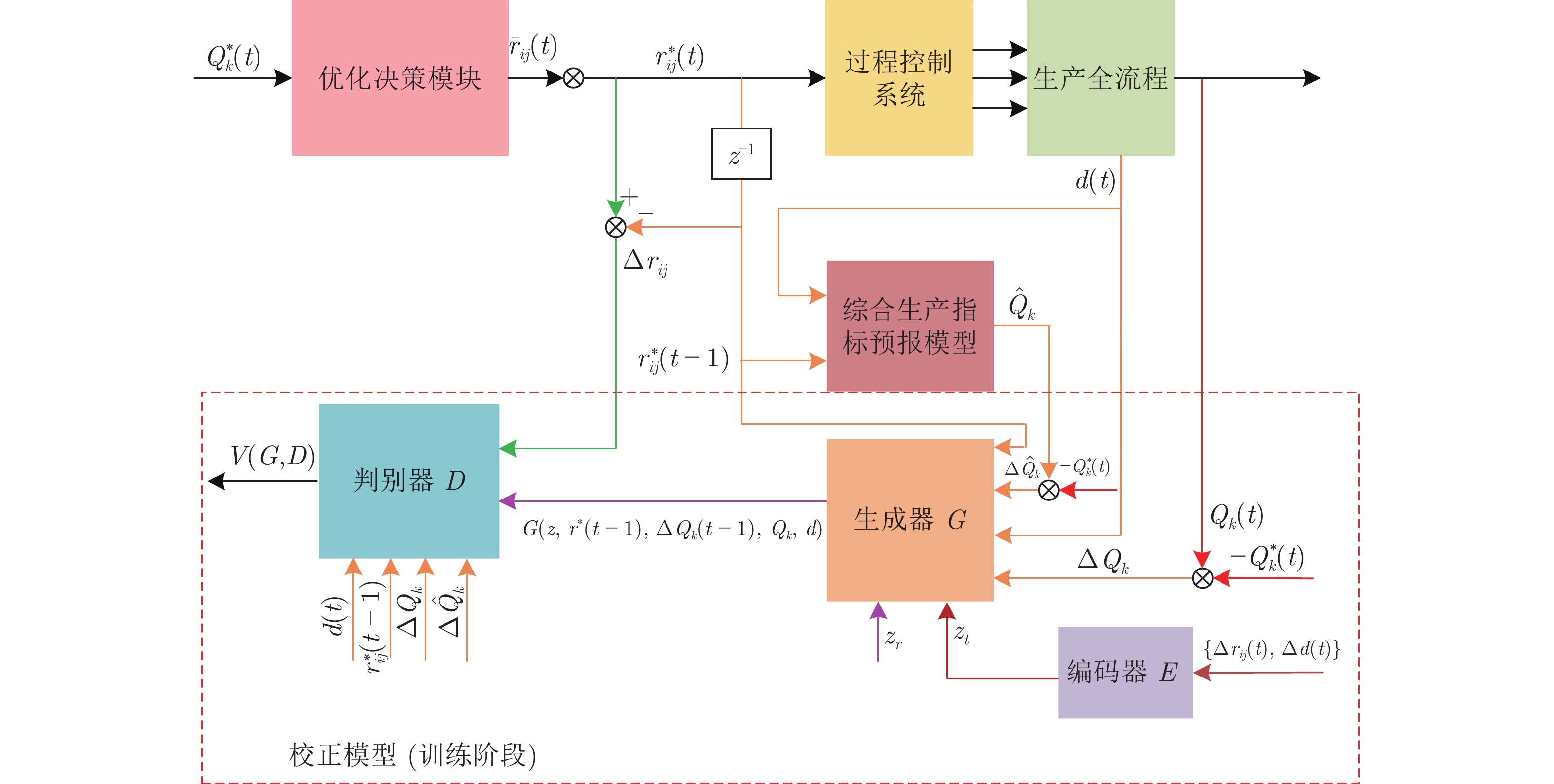

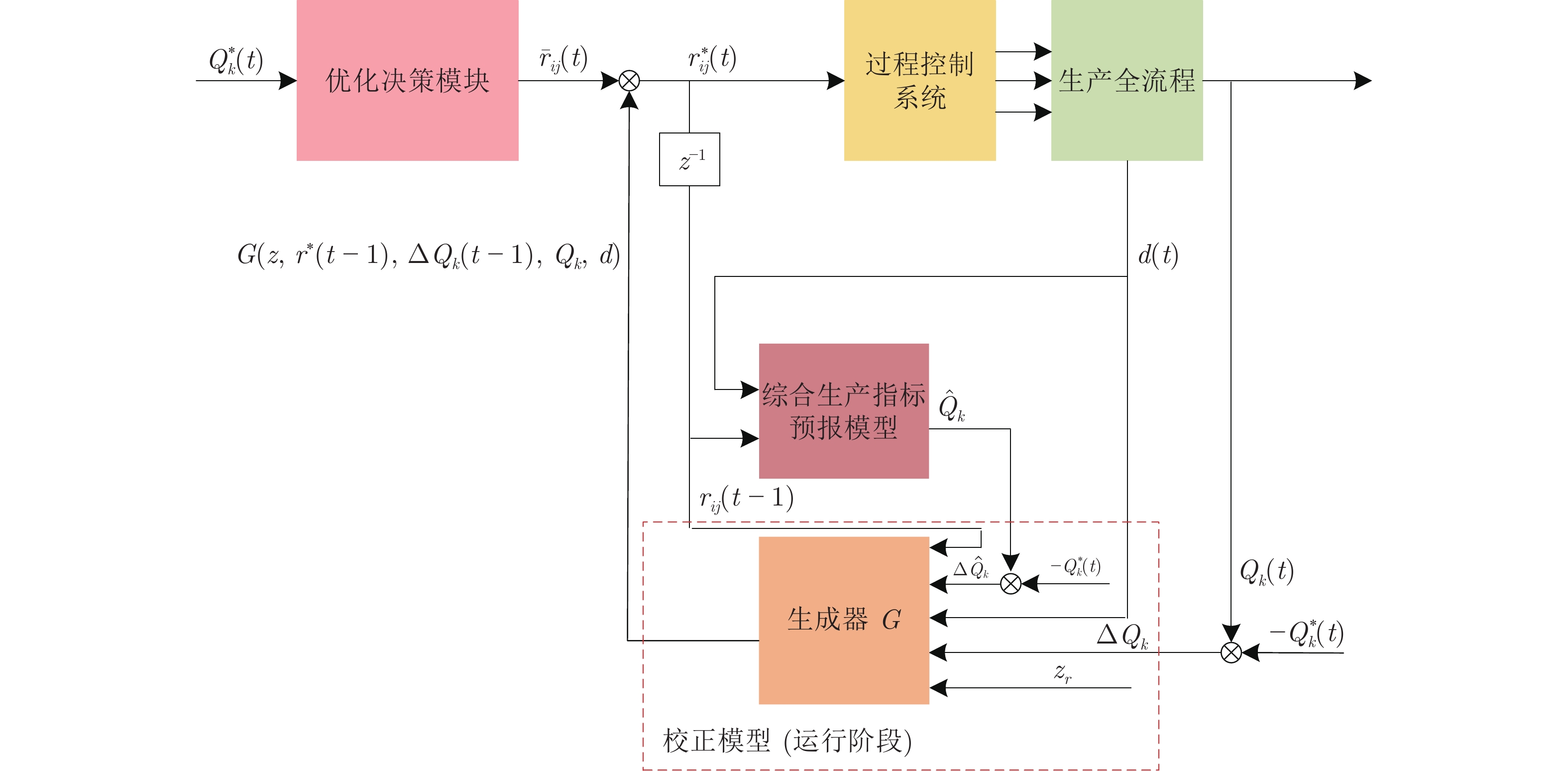

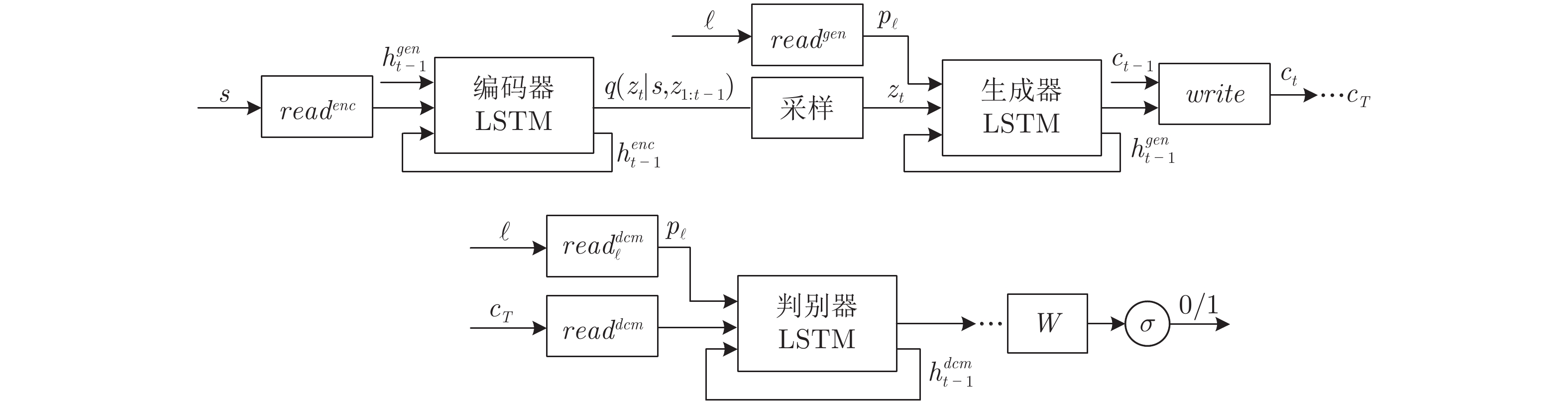

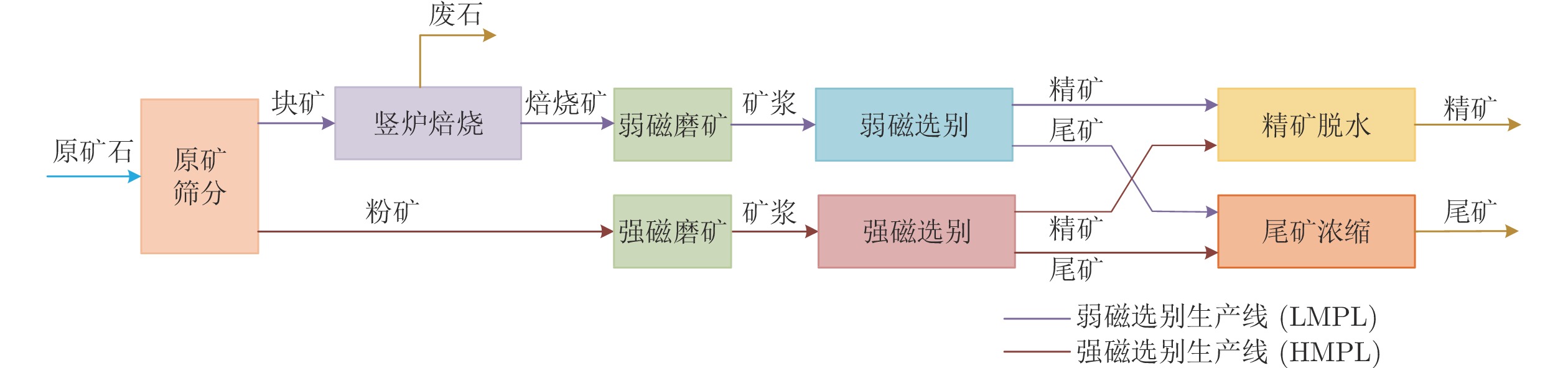

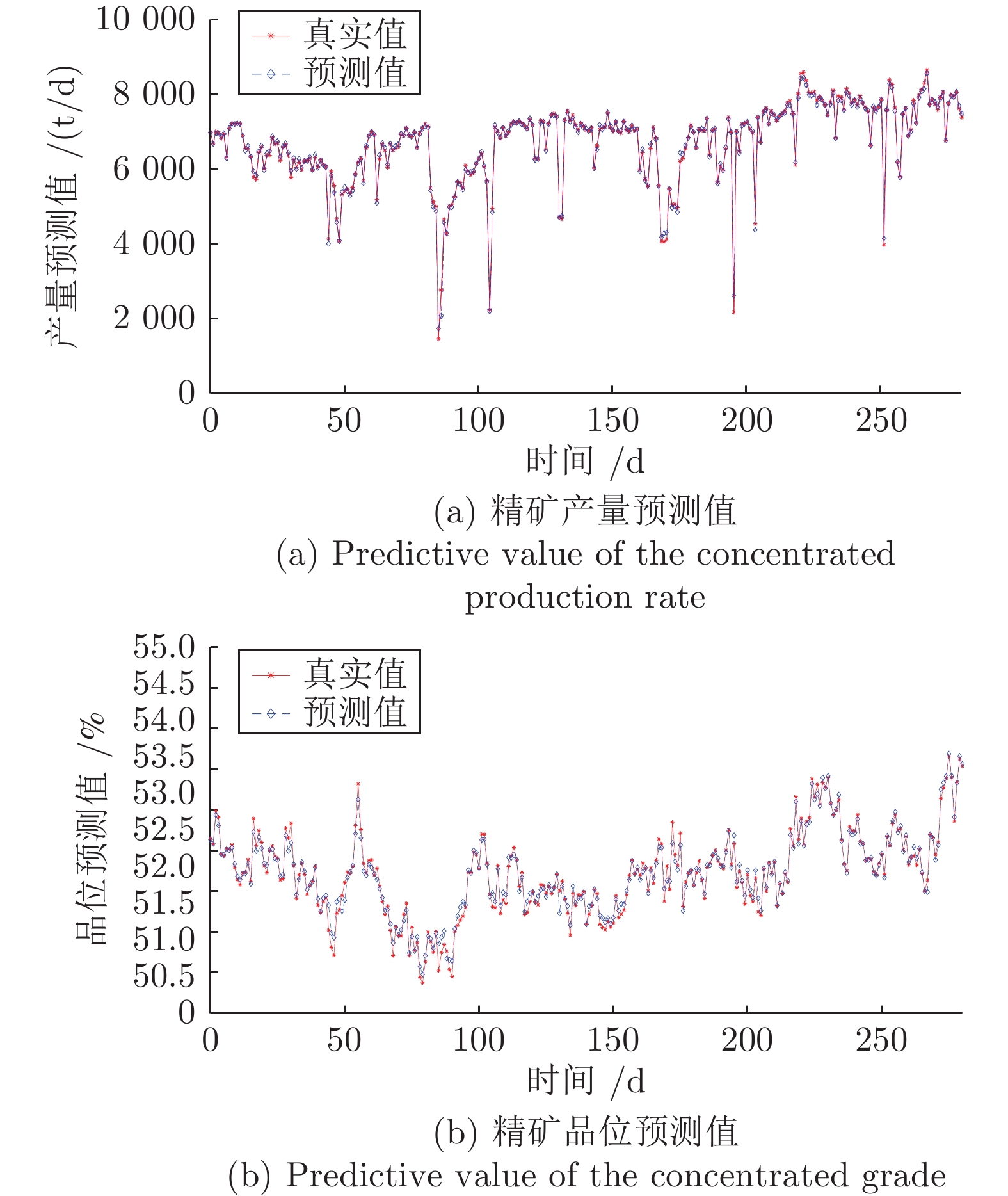

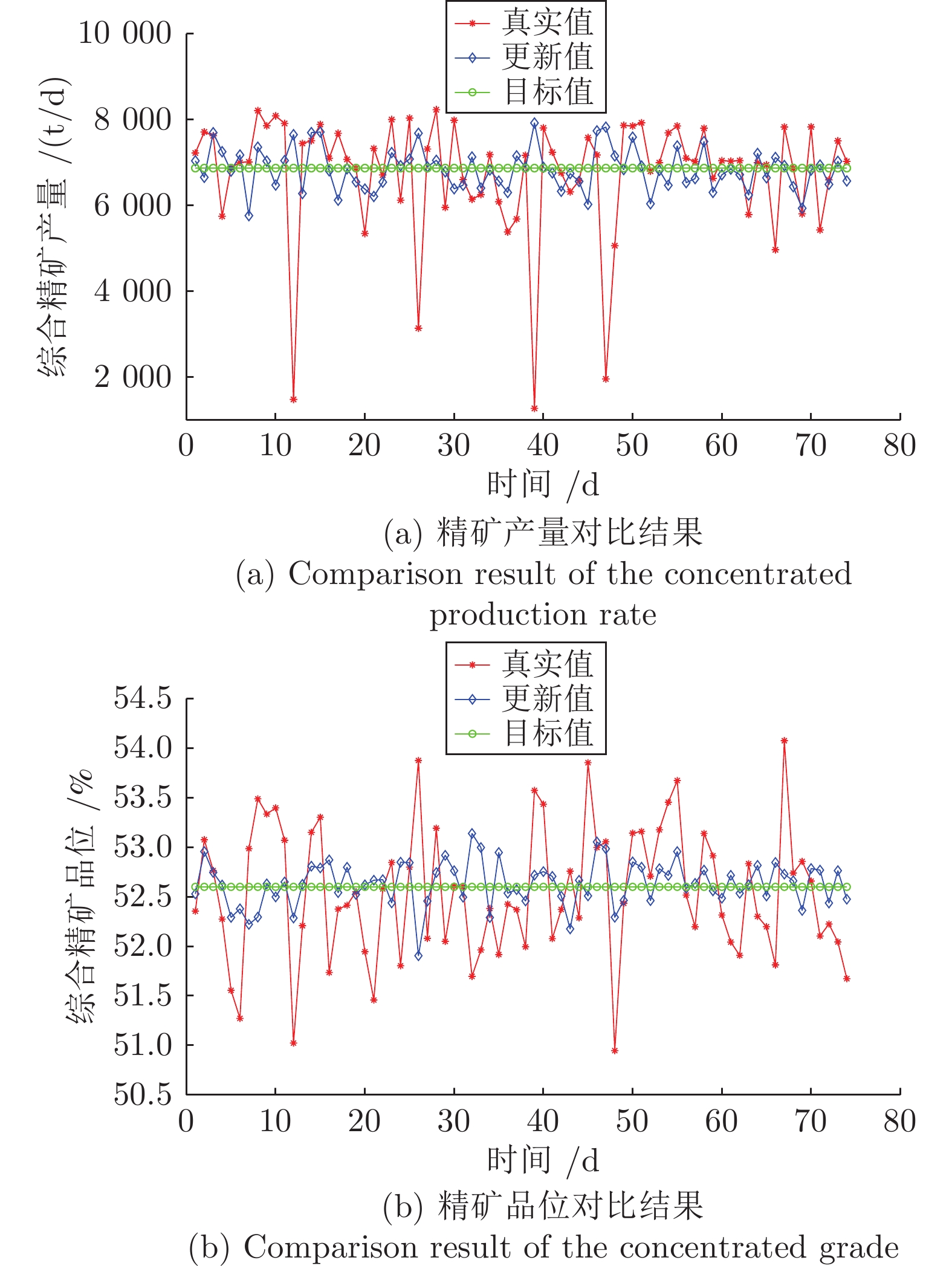

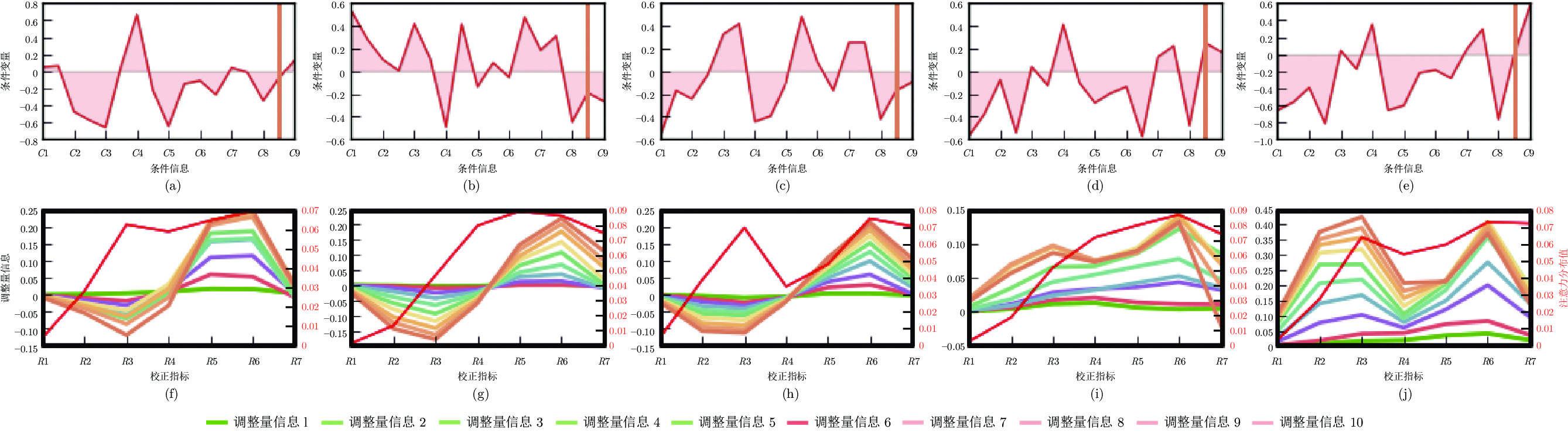

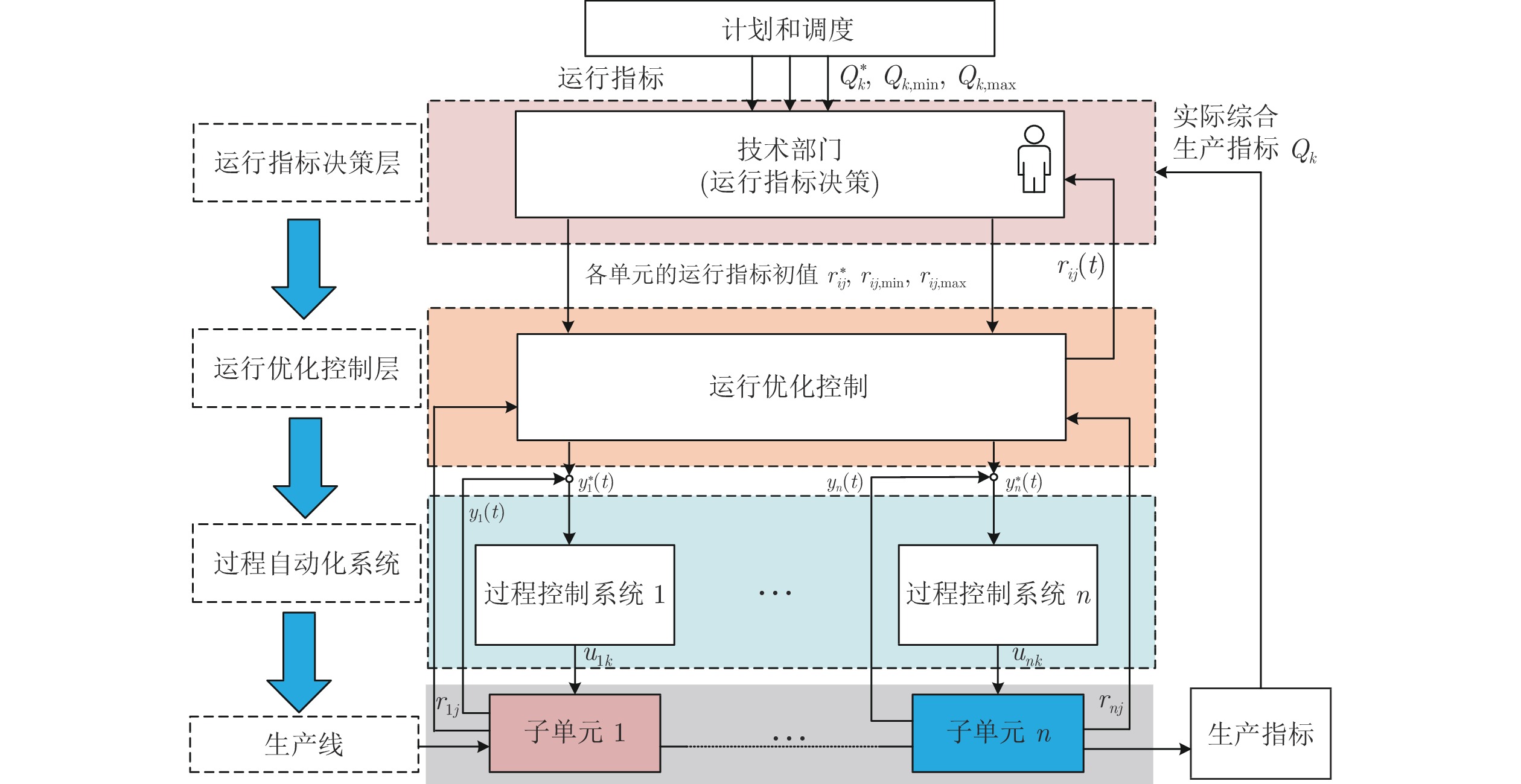

摘要: 针对工业过程运行指标反馈校正存在滞后及一步推理校正模型可解释性差的问题, 提出了基于递归注意力生成对抗网络(Recurrent attention generative adversarial networks, RAGAN)的运行指标前馈−反馈多步校正方法. 该方法采用基于负相关正则化的集成随机权神经网络, 建立综合生产指标预报模型, 为校正提供前馈信息补偿反馈校正的滞后性. 提出的RAGAN校正, 采用多步校正实现一次调整的思想, 将当前时刻运行指标映射到低维潜变量空间简化数据复杂度, 利用长短期记忆 (Long short-term memory, LSTM)模型实现数据的分步输入, 提高模型可解释性; 采用分布式注意力(Distributed attention, DA)机制构建数据读入网络, 使校正环节获取任务相关性更高的数据, 降低任务复杂度, 减小噪声干扰, 利用校正后的运行指标, 保证系统的综合指标尽可能地跟随设定值运行. 采用中国西部地区最大选矿厂实际数据的仿真实验, 验证了所提方法的有效性.Abstract: To address the problems of time delay in feedback correction and weak interpretability of the correction model of the operational indices, this paper proposes a feedforward-feedback multi-step correction method for operational indices based on the recurrent attention generative adversarial networks (RAGAN). A global production indices prediction model is adopted to provide feedforward information for the feedback correction and compensate the time delay, which is established by the integrated stochastic weight neural network based on negative correlation regularization. The proposed RAGAN based correction approach adopts the idea of multi-step correction to realize one-time adjustment, mapping current indices to low-dimensional latent variable space to simplify data complexity, the long short-term memory (LSTM) is used to realize the step-by-step input of data which can improve the interpretability of the proposed correction model. In addition, a distributed attention (DA) mechanism is adopted to construct a data sensing network, which enables the correction model to obtain more task-related data and reduce the complexity as well as noise interference. The corrected operational indices are able to ensure that the global production indices follow their target values as far as possible. Simulation experiments based on actual data collected from the largest mineral processing plant in western China verify the effectiveness of the proposed approach.

-

表 1 选矿过程的运行指标

Table 1 Operation index of the beneficiation process

生产线 工序 运行指标 弱磁选别(LMPL) 焙烧过程 r1: 磁选管回收率 磨矿过程 r2: 磨矿粒度 弱磁选别 r31: 弱磁精矿品位 r32: 弱磁尾矿品位 强磁选别(HMPL) 磨矿过程 r4: 磨矿粒度 强磁选别 r51: 强磁精矿品位 r52: 强磁尾矿品位 表 2 校正前后评价指标对比

Table 2 Comparison of evaluation indexes before and after correction

方法 MAP EM MIKDA DMGAN 0.2324 ± 0 1.2190 ± 0 0 RAGAN_p 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 表 3 不同校正方法对比

Table 3 Comparison of different correction methods

方法 MAP EM MIKDA DMGAN 0.0480 ± 0.0078 1.0708 ± 0.3157 0.2300 ± 0.0017 MLP 0.1174 ± 0.0094 0.4796 ± 0.0698 0.3365 ± 0.0041 RAGAN_b 0.0362 ± 0.0025 1.0496 ± 0.0589 0.4281 ± 0.0022 RAGAN_p 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 表 4 不同推理步长对模型性能的影响

Table 4 The effect of different reasoning steps on model performance

步长数 MAP EM MIKDA 1 0.0711 ± 0.0043 0.2034 ± 0.0289 0.7229 ± 0.0080 5 0.0433 ± 0.0032 0.8982 ± 0.0764 0.4541 ± 0.0038 10 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 15 0.0314 ± 0.0020 1.1687 ± 0.0396 0.4676 ± 0.0019 20 0.0363 ± 0.0023 0.9966 ± 0.0508 0.4490 ± 0.0040 表 5 不同潜变量维度对模型性能的影响

Table 5 The impact of different hidden variable dimensions on model performance

变量z的维数 MAP EM MIKDA 4 0.0306 ± 0.0023 0.6934 ± 0.0266 0.5011 ± 0.0019 10 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 20 0.0368 ± 0.0036 1.0000 ± 0.0619 0.3823 ± 0.0020 32 0.0449 ± 0.0035 1.1559 ± 0.0809 0.4094 ± 0.0033 64 0.0469 ± 0.0042 0.8329 ± 0.0512 0.4165 ± 0.0028 100 0.0450 ± 0.0040 0.9498 ± 0.0773 0.4155 ± 0.0016 表 6 不同高斯核数对模型性能的影响

Table 6 The impact of different Guassian kernels on model performance

高斯核数 MAP EM MIKDA {5, 1, 5} 0.0455 ± 0.0040 0.8264 ± 0.0621 0.4278 ± 0.0081 {5, 3, 5} 0.0508 ± 0.0040 0.5435 ± 0.0408 0.4654 ± 0.0090 {5, 4, 5} 0.0352 ± 0.0029 0.7671 ± 0.0630 0.4315 ± 0.0038 {5, 5, 5} 0.0461 ± 0.0033 0.5582 ± 0.0345 0.5075 ± 0.0027 {5, 7, 5} 0.0413 ± 0.0031 0.6542 ± 0.0417 0.4914 ± 0.0028 {5, 9, 5} 0.0333 ± 0.0028 0.6898 ± 0.0387 0.4944 ± 0.0100 {5, 4, 3} 0.0383 ± 0.0030 0.6246 ± 0.0415 0.5332 ± 0.0040 {5, 4, 5} 0.0352 ± 0.0029 0.7671 ± 0.0630 0.4315 ± 0.0038 {5, 4, 7} 0.0355 ± 0.0038 0.9458 ± 0.0598 0.4177 ± 0.0075 {5, 4, 9} 0.0349 ± 0.0028 0.9773 ± 0.0701 0.4371 ± 0.0038 {3, 4, 7} 0.0344 ± 0.0027 1.0734 ± 0.0570 0.4409 ± 0.0020 {5, 4, 7} 0.0355 ± 0.0038 0.9458 ± 0.0598 0.4177 ± 0.0075 {7, 4, 7} 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 {9, 4, 7} 0.0376 ± 0.0026 1.0355 ± 0.0521 0.4366 ± 0.0047 无高斯核 0.0347 ± 0.0022 1.9838 ± 0.0738 0.5216 ± 0.0021 表 7 不同TV损失权重对模型性能的影响

Table 7 The impact of different TV loss coefficients on model performance

方程损失 MAP EM MIKDA 0 0.0334 ± 0.0028 1.1894 ± 0.0427 0.4603 ± 0.0016 0.0001 0.0336 ± 0.0034 0.9965 ± 0.0705 0.4488 ± 0.0041 0.0010 0.0335 ± 0.0025 0.8879 ± 0.0532 0.4010 ± 0.0061 0.0100 0.0365 ± 0.0026 0.6869 ± 0.0465 0.4326 ± 0.0057 0.1000 0.0489 ± 0.0021 0.1963 ± 0.0081 0.7533 ± 0.0036 -

[1] Chai T Y, Ding J L, Wang H. Multi-objective hybrid intelligent optimization of operational indices for industrial processes and application. In: Proceedings of the 18th IFAC World Congress. Milano, Italy: 2011. 10517−10522 [2] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931-1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Acta Automatica Sinica, 2018, 44(11): 1931-1943(in Chinese) [3] Chai T. Operation optimization and feedback control of complex industrial processes. Acta Automatica Sinica, 2013, 39(11): 1744-1757(in Chinese) doi: 10.3724/SP.J.1004.2013.01744 [4] Papageorgiou E I, Salmeron J L. A Review of Fuzzy Cognitive Maps Research During the Last Decade. IEEE Transactions on Fuzzy Systems, 2013, 21(1): 66-79 doi: 10.1109/TFUZZ.2012.2201727 [5] Zhang B, Yang C, Zhu H, Shi P, Gui W. Controllable-domain-based fuzzy rule extraction for copper removal process control. IEEE Transactions on Fuzzy Systems, 2018, 26(3): 1744-1756 doi: 10.1109/TFUZZ.2017.2751000 [6] Gonzalez J L, Aguilar L T, Castillo O. A cognitive map and fuzzy inference engine model for online design and self fine-tuning of fuzzy logic controllers. International Journal of Entelligent Systems, 2009, 24(11): 1134-1173 doi: 10.1002/int.20379 [7] Mori J. Dynamic Bayesian network based networked process monitoring for fault propagation identification and root cause diagnosis of complex dynamic processes. In: Proceedings of the 10th IFAC International Symposium on Dynamics and Control of Process Systems. Mumbai, India: 2013. 678−683 [8] Chai T, Ding J, Wu F. Hybrid intelligent control for optimal operation of shaft furnace roasting process. Control Engineering Practice, 2011, 19(3): 264-275 doi: 10.1016/j.conengprac.2010.05.002 [9] Ding J, Chai T, Wang H, Chen H. Knowledge-based global operation of mineral processing under uncertainty. IEEE Transactions on Industrial Informatics, 2012, 8(4): 849-859 doi: 10.1109/TII.2012.2205394 [10] Kamsu-Foguem B, Rigal F, Mauget F. Mining association rules for the quality improvement of the production process. Expert Systems with Applications, 2013, 40(4): 1034-1045 doi: 10.1016/j.eswa.2012.08.039 [11] 王玲, 孟建瑶, 李俊飞, 彭开香. 基于多维时态关联规则的演化模糊推理预测算法. 自动化学报, 2018, 44(8): 1446-1459Wang Ling, Meng Jian-Yao, Li Jun-Fei, Peng Kai-Xiang. An evolving fuzzy inference algorithm with multi-dimensional temporal association rules. Acta Automatica Sinica, 2018, 44(8): 1446-1459 (in Chinese) [12] 丁进良, 杨翠娥, 陈立鹏, 柴天佑. 基于参考点预测的动态多目标优化算法. 自动化学报, 2017, 43(2): 313-320Ding Jin-Liang, Yang Cui-E, Chen Li-Peng, Chai Tian-You. Dynamic multi-objective optimization algorithm based on reference point prediction. Acta Automatica Sinica, 2017, 43(2): 313-320(in Chinese) [13] Zheng N Z, Ding J L, Chai T Y. DMGAN: Adversarial learning-based decision making for human-level plant-wide operation of process industries under uncertainties, IEEE Transactions on Neural Networks and Learning Systems, 2021, 32(3): 985−998 [14] Gregor K, Danihelka I, Graves A, Wierstra D. DRAW: A recurrent neural network for image generation. In: Proceedings of the International Conference on Machine Learning. Lille, France: 2015. [15] Kalchbrenner N, Danihelka I, Graves A. Grid long short-term memory [Online], available: https://arxiv.org/abs/1507.01526v3, January 6, 2015 [16] 李温鹏, 周平. 高炉铁水质量鲁棒正则化随机权神经网络建模. 自动化学报, 2020, 46(4): 721-733Li Wen-Peng, Zhou Ping. Robust regularized RVFLNs modeling of molten iron quality in blast furnace ironmaking. Acta Automatica Sinica, 2020, 46(4): 721-733(in Chinese) [17] 韩红桂, 张璐, 卢薇, 乔俊飞. 城市污水处理过程动态多目标智能优化控制研究. 自动化学报, 2021, 47(3): 620−629Han Hong-Gui, Zhang Lu, Lu Wei, Qiao Jun-Fei. Research on dynamic multiobjective intelligent optimal control for municipal wastewater treatment process. Acta Automatica Sinica, 2021, 47(3): 620−629(in Chinese) [18] Lu J, Ding, J, Dai X. Chai T. Ensemble stochastic configuration networks for estimating prediction intervals: a simultaneous robust training algorithm and its application, IEEE Transactions on Neural Networks and Learning Systems, 2020, 31(12): 5426-5440 doi: 10.1109/TNNLS.2020.2967816 [19] Schmidt W F, Kraaijveld M A, Duin R. Feedforward neural networks with random weights. In: Proceedings of the 11th IAPR International Conference on Pattern Recognition. Hague, Netherlands: 1992. 1−4 [20] Goodfellow I J, Pouget-Abadie J, Mirza M, Xu B, Warde-Farley D, Ozair S, et al. Generative adversarial networks. In: Proceedings of the 27th International Conference on Neural Information Processing Systems. Montreal, Canada: 2014. 2672−2680 [21] Mirza M, Osindero S. Conditional generative adversarial nets [Online], available: http://arxiv.org/abs/1411.1784, November 6,2014 [22] Radford A, Metz L, Chintala S. Unsupervised representation learning with deep convolutional generative adversarial networks. In: Proceedings of the 4th International Conference on Learning Representations. San Juan, USA: 2016. [23] Larsen A, Snderby S K, Larochelle H, Winther O. Autoencoding beyond pixels using a learned similarity metric [Online], ava-ilable: https://arxiv.org/abs/1512.09300, February 10, 2016 [24] Arjovsky M, Chintala S, Bottou L. Wasserstein GAN [Online], available: https://arxiv.org/abs/1701.07875, December 6, 2017 [25] Yu L, Zhang W, Wang J, Yu Y. SeqGAN: Sequence generative adversarial nets with policy gradient [Online], available: https://arxiv.org/abs/1609.05473v3, September 25, 2016 [26] Makhzani A, Shlens J, Jaitly N, Goodfellow I. Adversarial autoencoders. In: Proceedings of the 4th International Conference on Learning Representations. San Juan, UAS: 2016. -

下载:

下载: