-

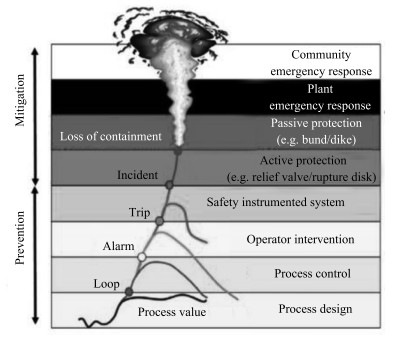

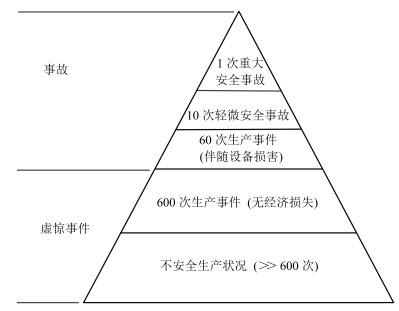

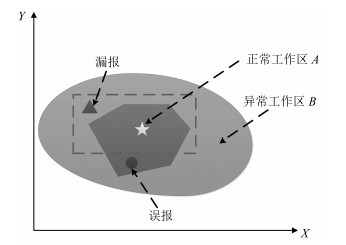

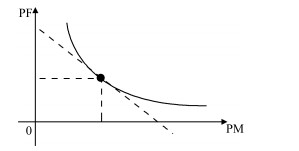

摘要: 作为现代工业过程运行的首道保护层,报警系统对保障过程安全、可靠和高效生产起着举足轻重的作用.然而,目前大多数工业报警系统存在着“报警泛滥”这一问题,严重影响了报警系统的应有功能.本文结合工业过程特点和报警管理生命周期,总结了导致“报警泛滥”的主要原因,并依据这些原因,从报警建模与报警根源分析、报警阈值设计、报警优先级划分、报警类型识别与处理、报警系统性能评估等分类综述了报警管理关键技术研究进展、报警管理框架以及工业报警规范、报警管理软件与应用现状.最后,探讨了报警管理领域存在的难题和新挑战.Abstract: As the first protective layer of modern industrial processes, the alarm system plays a decisive role in ensuring safety, reliability and efficient production of the process. However, most of the current industrial alarm systems are suffering from the common issue "alarm flood", which seriously affects the required function of the alarm system. In this paper, according to the characteristics of industrial processes and alarm management life cycle, five main reasons leading to "alarm flood" are summarized; the state of the art of key technologies, systematic frameworks, specifications, software packages and application status about alarm management are reviewed in terms of alarm modeling and root-cause analysis, alarm limit design, alarm prioritization, alarm type identification and processing, and alarm system performance assessment. Finally, problems and new challenges in the field of alarm management are discussed.

-

Key words:

- Alarm flood /

- alarm management /

- intelligent modeling /

- alarm design /

- industrial processes

-

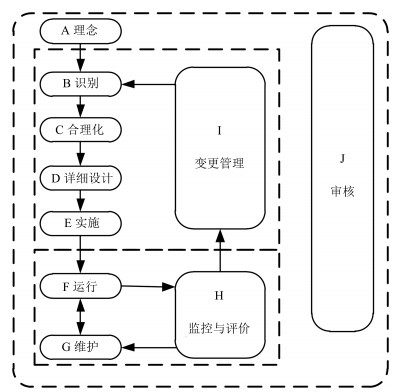

表 1 报警管理生命周期各阶段概述

Table 1 Alarm management lifecycle stages

标号 名称 各个阶段工作、任务 输入 输出 A 理念 报警管理过程定义和报警管理要求规格文件制定 目标和标准 报警理念和报警管理要求规格文件 B 识别 确定潜在报警 过程危险分析报告、过程流程图等 潜在报警列表 C 合理化 合理化、分类、优先级划分、建档 报警理念和潜在报警列表 主报警库, 报警设计要求 D 详细设计 基本报警设计、人机交互界面设计、先进报警设计 主报警库, 报警设计要求 完整报警设计 E 实施 安装报警, 初始化测试, 初始化训练 完整报警设计, 主报警库 操作报警, 报警响应流程 F 运行 操作员对报警作出响应, 复习训练 操作报警, 报警响应流程 报警数据 G 维护 维护修理和替换, 定期测试 报警监控报告, 报警理念 报警数据 H 监控与评价 报警数据监控、性能评价 报警数据, 报警理念 报警监控报告, 变更 I 变更管理 授权报警添加、修改和删除 报警理念, 提出的变更 授权的报警变更 J 审核 报警管理过程的定期审核 标准、报警理念和审核协议 改进建议 表 2 实际工业统计结果与EEMUA标准对比

Table 2 Comparison of performance metrics between real industry and benchmark

EEMUA标准 石油天然气 石化 电力 其他 平均报警数(天) 144 1200 1500 2000 900 最大报警数(10min) 10 220 180 350 180 -

[1] 杨帆, 萧德云.智能报警管理若干研究问题.计算机与应用化学, 2011, 28(12): 1485-1491 doi: 10.3969/j.issn.1001-4160.2011.12.001Yang Fan, Xiao De-Yun. Research topics of intelligent alarm management. Computers and Applied Chemistry, 2011, 28(12): 1485-1491 doi: 10.3969/j.issn.1001-4160.2011.12.001 [2] 朱群雄, 高慧慧, 刘菲菲, 彭荻, 徐圆, 顾祥柏.过程工业报警系统研究进展.计算机与应用化学, 2014, 31(2): 129-134 http://www.cnki.com.cn/Article/CJFDTOTAL-JSYH201402001.htmZhu Qun-Xiong, Gao Hui-Hui, Liu Fei-Fei, Peng Di, Xu Yuan, Gu Xiang-Bai. Research progress of alarm systems in the process industries. Computers and Applied Chemistry, 2014, 31(2): 129-134 http://www.cnki.com.cn/Article/CJFDTOTAL-JSYH201402001.htm [3] Wang J D, Yang F, Chen T W, Shah S L. An overview of industrial alarm systems: main causes for alarm overloading, research status, and open problems. IEEE Transactions on Automation Science and Engineering, 2016, 13(2): 1045-1061 doi: 10.1109/TASE.2015.2464234 [4] ISA. ANSI/ISA-18.2-2009 Management of alarm systems for the process industries. Durham, NC, USA: International Society of Automation, 2009. [5] Stauffer T, Clarke P. Using alarms as a layer of protection. Process Safety Progress, 2016, 35(1): 76-83 doi: 10.1002/prs.v35.1 [6] Health and Safety Executive. The explosion and fires at the Texaco refinery, Milford haven, 24 July 1994: a report of the investigation by the health and safety executive into the explosion and fires on the Pembroke cracking company plant at the Texaco refinery, Milford haven on 24 July 1994, ISBN 0717614131, 1997. [7] Powell-Price M. The explosion and fires at the Texaco Refinery, 24 July 1994. IChemE Loss Prevention Bulletin, 1997, 138: 3-10 http://enatech.jrc.ec.europa.eu/get_attachment?id=188 [8] Pariyani A, Seider W D, Oktem U G, Soroush M. Incidents investigation and dynamic analysis of large alarm databases in chemical plants: a fluidized-catalytic-cracking unit case study. Industrial and Engineering Chemistry Research, 2010, 49(17): 8062-8079 doi: 10.1021/ie9019648 [9] EEMUA. EEMUA-191-2013 alarm systems--a guide to design, management and procurement. London, UK: Engineering Equipment and Materials Users Association, 2013. [10] Rothenberg D H. Alarm Management for Process Control. New York, USA: Momentum Press, 2009. [11] NAMUR. NAMUR NA 102-2008 Alarm Management. NAMUR, 2008. [12] ERPI. Advanced Control Room Alarm System: Requirements and Implementation Guidance, EPRI Report 1010076, The Electric Power Research Institute (ERPI), 2005. [13] ASM. ASM consortium guideline: effective alarm management practice. Abnormal Situation Management Consortium (ASM), 2005. [14] API. API 1167 Pipeline SCADA Alarm Management. American Petroleum Institute (API), 2010. [15] IEC. IEC 68682 Management of alarm systems for the process industries. International Electrotechnical Commission (IEC), 2014. [16] ABB. AlarmInsight® enables effective response to process disturbances [Online], available: http://~library.e.abb.com, May 9, 2017 [17] ABB. AlarmInsight®-alarm rationalization tool enabling continous alarm lifecycle management [Online], available: http://~library.e.abb.com, May 9, 2017 [18] Honeywell. DynAmo® alarm management [Online], available: http://~www.honeywellprocess.com, May 9, 2017 [19] Emerson. DeltaV DCS-alarm management [Online], available: http://~www2.emersonprocess.com, May 9, 2017 [20] Exida. SILAlarmTM: alarm management|advanced rationallization tool [Online], available: http://www.exida.com/SILAlarm, May 9, 2017 [21] Siemens. The SIMATIC PCS 7: process control system [Online], available: http://~www.automation.siemens.com, May 9, 2017 [22] Gupta A, Giridhar A, Venkatasubramanian V, Reklaitis G V. Intelligent alarm management applied to continuous pharmaceutical tablet manufacturing: an integrated approach. Industrial and Engineering Chemistry Research, 2013, 52(35): 12357-12368 doi: 10.1021/ie3035042 [23] Hu W K, Afzal M S, Brandt G, Lau E, Chen T W, Shah S L. An application of advanced alarm management tools to an oil sand extraction plant. IFAC-PapersOnLine, 2015, 48(8): 641-646 doi: 10.1016/j.ifacol.2015.09.040 [24] Li D W, Hu J H, Wang H, Huang W J. A distributed parallel alarm management strategy for alarm reduction in chemical plants. Journal of Process Control, 2015, 34: 117-125 doi: 10.1016/j.jprocont.2015.07.008 [25] Hu J Q, Yi Y. A two-level intelligent alarm management framework for process safety. Safety Science, 2016, 82: 432-444 doi: 10.1016/j.ssci.2015.10.005 [26] Soares V B, Pinto J C, de Souza Jr M B. Alarm management practices in natural gas processing plants. Control Engineering Practice, 2016, 55: 185-196 doi: 10.1016/j.conengprac.2016.07.004 [27] Venkatasubramanian V, Rengaswamy R, Yin K W, Kavuri S N. A review of process fault detection and diagnosis: part Ⅰ: quantitative model-based methods. Computers and Chemical Engineering, 2003, 27(3): 293-311 doi: 10.1016/S0098-1354(02)00160-6 [28] Venkatasubramanian V, Rengaswamy R, Kavuri S N. A review of process fault detection and diagnosis: part Ⅱ: qualitative models and search strategies. Computers and Chemical Engineering, 2003, 27(3): 313-326 doi: 10.1016/S0098-1354(02)00161-8 [29] Venkatasubramanian V, Rengaswamy R, Kavuri S N, Yin K W. A review of process fault detection and diagnosis: part Ⅲ: process history based methods. Computers and Chemical Engineering, 2003, 27(3): 327-346 doi: 10.1016/S0098-1354(02)00162-X [30] Yin S, Ding S X, Xie X C, Luo H. A review on basic data-driven approaches for industrial process monitoring. IEEE Transactions on Industrial Electronics, 2014, 61(11): 6418-6428 doi: 10.1109/TIE.2014.2301773 [31] Gao Z W, Cecati C, Ding S X. A survey of fault diagnosis and fault-tolerant techniques--part Ⅰ: fault diagnosis with model-based and signal-based approaches. IEEE Transactions on Industrial Electronics, 2015, 62(6): 3757-3767 doi: 10.1109/TIE.2015.2417501 [32] Yang F, Xiao D Y. Progress in root cause and fault propagation analysis of large-scale industrial processes. Journal of Control Science and Engineering, 2012, 2012: Article No. 478373 http://www.oalib.com/paper/59754 [33] Yang F, Duan P, Shah S L, Chen T W. Capturing Connectivity and Causality in Complex Industrial Processes. New York, NY, USA: Springer, 2014. [34] Duan P, Chen T W, Shah S L, Yang F. Methods for root cause diagnosis of plant-wide oscillations. AIChE Journal, 2014, 60(6): 2019-2034 doi: 10.1002/aic.14391 [35] 桂卫华, 阳春华, 陈晓方, 王雅琳.有色冶金过程建模与优化的若干问题及挑战.自动化学报, 2013, 39(3): 197-207 http://www.aas.net.cn/CN/abstract/abstract17799.shtmlGui Wei-Hua, Yang Chun-Hua, Chen Xiao-Fang, Wang Ya-Lin. Modeling and optimization problems and challenges arising in nonferrous metallurgical processes. Acta Automatica Sinica, 2013, 39(3): 197-207 http://www.aas.net.cn/CN/abstract/abstract17799.shtml [36] Sadrameli S M. Thermal/catalytic cracking of hydrocarbons for the production of olefins: a state-of-the-art review Ⅰ: thermal cracking review. Fuel, 2015, 140: 102-115 doi: 10.1016/j.fuel.2014.09.034 [37] Maurya M R, Rengaswamy R, Venkatasubramanian V. Application of signed digraphs-based analysis for fault diagnosis of chemical process flowsheets. Engineering Applications of Artificial Intelligence, 2004, 17(5): 501-518 doi: 10.1016/j.engappai.2004.03.007 [38] He B, Chen T, Yang X H. Root cause analysis in multivariate statistical process monitoring: integrating reconstruction-based multivariate contribution analysis with fuzzy-signed directed graphs. Computers and Chemical Engineering, 2014, 64: 167-177 doi: 10.1016/j.compchemeng.2014.02.014 [39] 杨帆, 萧德云. SDG建模及其应用的进展.控制理论与应用, 2005, 22(5): 767-774 http://www.cnki.com.cn/Article/CJFDTOTAL-KZLY200505018.htmYang Fan, Xiao De-Yun. Review of SDG modeling and its application. Control Theory and Applications, 2005, 22(5): 767-774 http://www.cnki.com.cn/Article/CJFDTOTAL-KZLY200505018.htm [40] Yang F, Xiao D Y, Shah S L. Qualitative fault detection and hazard analysis based on signed directed graphs for large-scale complex systems. Fault Detection. Rijeka, Croatia: InTech, 2010. 15-50 [41] Dahlstrand F. Consequence analysis theory for alarm analysis. Knowledge-Based Systems, 2002, 15(1-2): 27-36 doi: 10.1016/S0950-7051(01)00118-6 [42] Jiang H L, Patwardhan R, Shah S L. Root cause diagnosis of plant-wide oscillations using the concept of adjacency matrix. Journal of Process Control, 2009, 19(8): 1347-1354 doi: 10.1016/j.jprocont.2009.04.013 [43] Yim S Y, Ananthakumar H G, Benabbas L, Horch A, Drath R, Thornhill N F. Using process topology in plant-wide control loop performance assessment. Computers and Chemical Engineering, 2006, 31(2): 86-99 doi: 10.1016/j.compchemeng.2006.05.004 [44] Schleburg M, Christiansen L, Thornhill N F, Fay A. A combined analysis of plant connectivity and alarm logs to reduce the number of alerts in an automation system. Journal of Process Control, 2013, 23(6): 839-851 doi: 10.1016/j.jprocont.2013.03.010 [45] Bauer M, Thornhill N F. A practical method for identifying the propagation path of plant-wide disturbances. Journal of Process Control, 2008, 18(7-8): 707-719 doi: 10.1016/j.jprocont.2007.11.007 [46] Hu W K, Wang J D, Chen T W. A new method to detect and quantify correlated alarms with occurrence delays. Computers and Chemical Engineering, 2015, 80: 189-198 doi: 10.1016/j.compchemeng.2015.05.028 [47] Yuan T, Qin S J. Root cause diagnosis of plant-wide oscillations using Granger causality. Journal of Process Control, 2014, 24(2): 450-459 doi: 10.1016/j.jprocont.2013.11.009 [48] Gigi S, Tangirala A K. Quantitative analysis of directional strengths in jointly stationary linear multivariate processes. Biological Cybernetics, 2010, 103(2): 119-133 doi: 10.1007/s00422-010-0386-6 [49] Bauer M, Cox J W, Caveness M H, Downs J J, Thornhill N F. Finding the direction of disturbance propagation in a chemical process using transfer entropy. IEEE Transactions on Control Systems Technology, 2007, 15(1): 12-21 doi: 10.1109/TCST.2006.883234 [50] Duan P, Yang F, Chen T W, Shah S L. Direct causality detection via the transfer entropy approach. IEEE Transactions on Control Systems Technology, 2013, 21(6): 2052-2066 doi: 10.1109/TCST.2012.2233476 [51] Duan P, Yang F, Shah S L, Chen T W. Transfer zero-entropy and its application for capturing cause and effect relationship between variables. IEEE Transactions on Control Systems Technology, 2015, 23(3): 855-867 doi: 10.1109/TCST.2014.2345095 [52] Wang J, Li H G, Huang J W, Su C. A data similarity based analysis to consequential alarms of industrial processes. Journal of Loss Prevention in the Process Industries, 2015, 35: 29-34 doi: 10.1016/j.jlp.2015.03.005 [53] Yu J, Rashid M M. A novel dynamic Bayesian network-based networked process monitoring approach for fault detection, propagation identification, and root cause diagnosis. AIChE Journal, 2013, 59(7): 2348-2365 doi: 10.1002/aic.v59.7 [54] Mori J, Mahalec V, Yu J. Identification of probabilistic graphical network model for root-cause diagnosis in industrial processes. Computers and Chemical Engineering, 2014, 71: 171-209 doi: 10.1016/j.compchemeng.2014.07.022 [55] Cecílio I M, Ottewill J R, Pretlove J, Thornhill N F. Nearest neighbors method for detecting transient disturbances in process and electromechanical systems. Journal of Process Control, 2014, 24(9): 1382-1393 doi: 10.1016/j.jprocont.2014.06.007 [56] Barocio E, Pal B C, Fabozzi D, Thornhill N F. Detection and visualization of power system disturbances using principal component analysis. In: Proceedings of the 2013 IREP Symposium Bulk Power System Dynamics and Control-Ⅸ Optimization, Security and Control of the Emerging Power Grid. Rethymno, Greece: IEEE, 2013. 1-10 [57] Jacobs S A, Dagnino A. Large-scale industrial alarm reduction and critical events mining using graph analytics on Spark. In: Proceedings of the 2nd International Conference on Big Data Computing Service and Applications (BigDataService). Oxford, UK: IEEE, 2016. 66-71 [58] Hu W K, Al-Dabbagh A W, Chen T W, Shah S L. Process discovery of operator actions in response to univariate alarms. IFAC-PapersOnLine, 2016, 49(7): 1026-1031 doi: 10.1016/j.ifacol.2016.07.337 [59] Yang F, Shah S L, Xiao D Y. SDG (signed directed graph) based process description and fault propagation analysis for a tailings pumping process. IFAC Proceedings Volumes, 2010, 43(9): 50-55 doi: 10.3182/20100802-3-ZA-2014.00011 [60] Yang F, Sirish L S, Xiao D Y. Signed directed graph modeling of industrial processes and their validation by data-based methods. In: Proceedings of the 2010 Conference on Control and Fault-Tolerant Systems (SysTol). Nice, France: IEEE, 2010. 387-392 [61] Wang Y M, Yang F, Lv N, Xu H P, Ye H, Li W C, Xu P, Song L M, Usadi A K. Statistical root cause analysis of novel faults based on digraph models. Chemical Engineering Research and Design, 2013, 91(1): 87-99 doi: 10.1016/j.cherd.2012.06.010 [62] Gao H H, Xu Y, Gu X B, Lin X Y, Zhu Q X. Systematic rationalization approach for multivariate correlated alarms based on interpretive structural modeling and Likert scale. Chinese Journal of Chemical Engineering, 2015, 23(12): 1987-1996 doi: 10.1016/j.cjche.2015.11.009 [63] Gao H H, Xu Y, Zhu Q X. Spatial interpretive structural model identification and AHP-based multimodule fusion for alarm root-cause diagnosis in chemical processes. Industrial and Engineering Chemistry Research, 2016, 55(12): 3641-3658 doi: 10.1021/acs.iecr.5b04268 [64] de Souza J C S, Meza E M, Schilling M T, Do Coutto Filho M B. Alarm processing in electrical power systems through a neuro-fuzzy approach. IEEE Transactions on Power Delivery, 2004, 19(2): 537-544 doi: 10.1109/TPWRD.2003.823205 [65] Larsson J E, Öhman B, Calzada A, Nihlwing C, Jokstad H, Kristianssen L I, Kvalem J, Lind M. A revival of the alarm system: making the alarm list useful during incidents. In: Proceedings of the 5th International Topical Meeting on Nuclear Plant Instrumentation Controls, and Human Machine Interface Technology. Albuquerque, New Mexico, USA: American Nuclear Society, 2006. [66] Us T, Jensen N, Lind M, J'ørgensen S B. Fundamental principles of alarm design. International Journal of Nuclear Safety and Simulation, 2011, 2(1): 44-51 https://www.researchgate.net/profile/Niels_Jensen7/publication/266228393_Fundamental_principles_of_alarm_design/links/54b7b2920cf24eb34f6ecee3.pdf?inViewer=true&disableCoverPage=true&origin=publication_detail [67] Cauvin S, Cordier M O, Dousson C, Laborie P, Lé vy F, Montmain J, Porcheron M, Servet I, Trave-Massuyes L. Monitoring and alarm interpretation in industrial environments. Aicommunications , 1998, 11(3-4): 139-173 https://www.researchgate.net/profile/Louise_Trave-Massuyes/publication/220308739_Monitoring_and_Alarm_Interpretation_in_Industrial_Environments/links/00b4952a96c844dfc8000000.pdf?origin=publication_detail [68] Abele L, Anic M, Gutmann T, Folmer J, Kleinsteuber M, Vogel-Heuser B. Combining knowledge modeling and machine learning for alarm root cause analysis. IFAC Proceedings Volumes, 2013, 46(9): 1843-1848 doi: 10.3182/20130619-3-RU-3018.00057 [69] Wang J D, Xu J W, Zhu D. Online root-cause analysis of alarms in discrete Bayesian networks with known structures. In: Proceedings of the 11th World Congress on Intelligent Control and Automation (WCICA). Shenyang, China: IEEE, 2014. 467-472 [70] Kezunovic M, Guan Y F. Intelligent alarm processing: from data intensive to information rich. In: Proceedings of the 42nd Hawaii International Conference on System Sciences. Big Island, HI, USA: IEEE, 2009. 1-8 [71] Young D J, Lo K L, McDonald J R, Howard R, Rye J. Development of a practical expert system for alarm processing (power systems). IEE Proceedings C--Generation, Transmission and Distribution, 1992, 139(5): 437-447 doi: 10.1049/ip-c.1992.0061 [72] McDonald J R, Burt G M, Young D J. Alarm processing and fault diagnosis using knowledge based systems for transmission and distribution network control. IEEE Transactions on Power Systems, 1992, 7(3): 1292-1298 doi: 10.1109/59.207347 [73] Wen F S, Chang C S. Tabu search approach to alarm processing in power systems. IEE Proceedings--Generation, Transmission and Distribution, 1997, 144(1): 31-38 doi: 10.1049/ip-gtd:19970716 [74] Wen F S, Chang C S, Fu W H. New approach to alarm processing in power systems based on the set covering theory and a refined genetic algorithm. Electric Machines and Power Systems, 1998, 26(1): 53-67 doi: 10.1080/07313569808955807 [75] Simeu-Abazi Z, Lefebvre A, Derain J P. A methodology of alarm filtering using dynamic fault tree. Reliability Engineering and System Safety, 2011, 96(2): 257-266 doi: 10.1016/j.ress.2010.09.005 [76] Guo W X, Wen F S, Liao Z W, Wei L H, Xin J B. An analytic model-based approach for power system alarm processing employing temporal constraint network. IEEE Transactions on Power Delivery, 2010, 25(4): 2435-2447 doi: 10.1109/TPWRD.2009.2032054 [77] Wei L H, Guo W X, Wen F S, Ledwich G, Liao Z W, Xin J B. An online intelligent alarm-processing system for digital substations. IEEE Transactions on Power Delivery, 2011, 26(3): 1615-1624 doi: 10.1109/TPWRD.2011.2117445 [78] Dubois L, Forět J M, Mack P, Ryckaert L. Advanced logic for alarm and event processing: methods to reduce cognitive load for control room operators. IFAC Proceedings Volumes, 2010, 43(13): 158-163 doi: 10.3182/20100831-4-FR-2021.00029 [79] Lee J W, Kim J T, Park J C, Hwang I K, Lyu S P. Computer-based alarm processing and presentation methods in nuclear power plants. International Scholarly and Scientific Research and Innovation, 2010, 4(5): 940-944 https://www.researchgate.net/publication/236357561_Nuclear_Power_Plant_Alarm_Prioritization_NPPAP_Program_status_report_January_1_1983-September_31_1983 [80] Thambirajah J, Benabbas L, Bauer M, Thornhill N F. Cause-and-effect analysis in chemical processes utilizing XML, plant connectivity and quantitative process history. Computers and Chemical Engineering, 2009, 33(2): 503-512 doi: 10.1016/j.compchemeng.2008.10.002 [81] Chiang L H, Braatz R D. Process monitoring using causal map and multivariate statistics: fault detection and identification. Chemometrics and Intelligent Laboratory Systems, 2003, 65(2): 159-178 doi: 10.1016/S0169-7439(02)00140-5 [82] Rodrigo V, Chioua M, Hagglund T, Hollender M. Causal analysis for alarm flood reduction. IFAC-PapersOnLine, 2016, 49(7): 723-728 doi: 10.1016/j.ifacol.2016.07.269 [83] Folmer J, Pantförder D, Vogel-Heuser B. An analytical alarm flood reduction to reduce operator's workload. Human-Computer Interaction. Users and Applications. Berlin, Heidelberg, Germany: Springer, 2011. 297-306 [84] Folmer J, Vogel-Heuser B. Computing dependent industrial alarms for alarm flood reduction. In: Proceedings of the 9th International Multi-Conference on Systems, Signals and Devices (SSD). Chemnitz, Germany: IEEE, 2012. 1-6 [85] Folmer J, Schuricht F, Vogel-Heuser B. Detection of temporal dependencies in alarm time series of industrial plants. IFAC Proceedings Volumes, 2014, 47(3): 1802-1807 doi: 10.3182/20140824-6-ZA-1003.01897 [86] Ahmed K, Izadi I, Chen T W, Joe D, Burton T. Similarity analysis of industrial alarm flood data. IEEE Transactions on Automation Science and Engineering, 2013, 10(2): 452-457 doi: 10.1109/TASE.2012.2230627 [87] Cheng Y, Izadi I, Chen T W. Pattern matching of alarm flood sequences by a modified Smith-Waterman algorithm. Chemical Engineering Research and Design, 2013, 91(6): 1085-1094 doi: 10.1016/j.cherd.2012.11.001 [88] Charbonnier S, Bouchair N, Gayet P. Fault isolation by comparing alarm lists using a symbolic sequence matching algorithm. IFAC Proceedings Volumes, 2014, 47(3): 7085-7090 doi: 10.3182/20140824-6-ZA-1003.00892 [89] Charbonnier S, Bouchair N, Gayet P. A weighted dissimilarity index to isolate faults during alarm floods. Control Engineering Practice, 2015, 45: 110-122 doi: 10.1016/j.conengprac.2015.09.004 [90] 陈忠圣, 高慧慧, 徐圆, 朱群雄.基于离散傅里叶变换的过程工业报警泛滥序列聚类分析及应用.化工学报, 2016, 67(3): 788-796 http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201603016.htmChen Zhong-Sheng, Gao Hui-Hui, Xu Yuan, Zhu Qun-Xiong. Discrete Fourier transform-based alarm flood sequence cluster analysis and applications in process industry. CIESC Journal, 2016, 67(3): 788-796 http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201603016.htm [91] Hu W K, Wang J D, Chen T W. Fast sequence alignment for comparing industrial alarm floods. IFAC-PapersOnLine, 2015, 48(8): 647-652 doi: 10.1016/j.ifacol.2015.09.041 [92] Hu W K, Wang J D, Chen T W. A local alignment approach to similarity analysis of industrial alarm flood sequences. Control Engineering Practice, 2016, 55: 13-25 doi: 10.1016/j.conengprac.2016.05.021 [93] Izadi I, Shah S L, Shook D S, Kondaveeti S R, Chen T W. A framework for optimal design of alarm systems. IFAC Proceedings Volumes, 2009, 42(8): 651-656 doi: 10.3182/20090630-4-ES-2003.00108 [94] Cheng Y, Izadi I, Chen T W. On optimal alarm filter design. In: Proceedings of the 2011 International Symposium on Advanced Control of Industrial Processes (ADCONIP). Hangzhou, China: IEEE, 2011. 139-145 [95] Cheng Y, Izadi I, Chen T W. Optimal alarm signal processing: filter design and performance analysis. IEEE Transactions on Automation Science and Engineering, 2013, 10(2): 446-451 doi: 10.1109/TASE.2012.2233472 [96] Adnan N A, Izadi I. On detection delays of filtering in industrial alarm systems. In: Proceedings of the 21st Mediterranean Conference on Control and Automation (MED). Chania, Greece: IEEE, 2013. 113-118 [97] Tan W, Sun Y K, Azad I I, Chen T W. Design of univariate alarm systems via rank order filters. Control Engineering Practice, 2017, 59: 55-63 doi: 10.1016/j.conengprac.2016.11.005 [98] Naghoosi E, Izadi I, Chen T W. A study on the relation between alarm deadbands and optimal alarm limits. In: Proceedings of the 2011 American Control Conference (ACC). San Francisco, CA, USA: IEEE, 2011. 3627-3632 [99] Kondaveeti S R, Izadi I, Shah S L, Chen T W. On the use of delay timers and latches for efficient alarm design. In: Proceedings of the 19th Mediterranean Conference on Control and Automation (MED). Corfu, Greece: IEEE, 2011. 970-975 [100] Adnan N A, Izadi I, Chen T W. On expected detection delays for alarm systems with deadbands and delay-timers. Journal of Process Control, 2011, 21(9): 1318-1331 doi: 10.1016/j.jprocont.2011.06.019 [101] Adnan N A, Cheng Y, Izadi I, Chen T W. Study of generalized delay-timers in alarm configuration. Journal of Process Control, 2013, 23(3): 382-395 doi: 10.1016/j.jprocont.2012.12.013 [102] Zhu J F, Shu Y D, Zhao J S, Yang F. A dynamic alarm management strategy for chemical process transitions. Journal of Loss Prevention in the Process Industries, 2014, 30: 207-218 doi: 10.1016/j.jlp.2013.07.008 [103] Xu X B, Li S B, Song X J, Wen C L, Xu D L. The optimal design of industrial alarm systems based on evidence theory. Control Engineering Practice, 2016, 46: 142-156 doi: 10.1016/j.conengprac.2015.10.014 [104] Bristol E H. Improved process control alarm operation. ISA Transactions, 2001, 40(2): 191-205 doi: 10.1016/S0019-0578(00)00004-5 [105] Brooks R, Thorpe R, Wilson J. A new method for defining and managing process alarms and for correcting process operation when an alarm occurs. Journal of Hazardous Materials, 2004, 115(1-3): 169-174 doi: 10.1016/j.jhazmat.2004.05.040 [106] Kondaveeti S R, Shah S L, Izadi I. Application of multivariate statistics for efficient alarm generation. IFAC Proceedings Volumes, 2009, 42(8): 657-662 doi: 10.3182/20090630-4-ES-2003.00109 [107] Izadi I, Shah S L, Shook D S, Chen T W. An introduction to alarm analysis and design. IFAC Proceedings Volumes, 2009, 42(8): 645-650 doi: 10.3182/20090630-4-ES-2003.00107 [108] Yang F, Shah S L, Xiao D Y. Correlation analysis of alarm data and alarm limit design for industrial processes. In: Proceedings of the 2010 American Control Conference (ACC). Baltimore, MD, USA: IEEE, 2010. 5850-5855 [109] Xu S C, Adhitya A, Srinivasan R. Hybrid model-based framework for alarm anticipation. Industrial and Engineering Chemistry Research, 2014, 53(13): 5182-5193 doi: 10.1021/ie4014953 [110] Zang H, Li H G. Optimization of process alarm thresholds: a multidimensional kernel density estimation approach. Process Safety Progress, 2014, 33(3): 292-298 doi: 10.1002/prs.v33.3 [111] Han L, Gao H H, Xu Y, Zhu Q X. Combining FAP, MAP and correlation analysis for multivariate alarm thresholds optimization in industrial process. Journal of Loss Prevention in the Process Industries, 2016, 40: 471-478 doi: 10.1016/j.jlp.2016.01.022 [112] Gao H H, Liu F F, Zhu Q X. A correlation consistency based multivariate alarm thresholds optimization approach. ISA Transactions, 2016, 65: 37-43 doi: 10.1016/j.isatra.2016.09.014 [113] Chang Y J, Khan F I, Ahmed S. A risk-based approach to design warning system for processing facilities. Process Safety and Environmental Protection, 2011, 89(5): 310-316 doi: 10.1016/j.psep.2011.06.003 [114] Ahmed S, Gabbar H A, Chang Y J, Khan F I. Risk based alarm design: a systems approach. In: Proceedings of the 2011 International Symposium on Advanced Control of Industrial Processes (ADCONIP). Hangzhou, China: IEEE, 2011. 42-47 [115] Zhu Q X, Geng Z Q. A new fuzzy clustering-ranking algorithm and its application in process alarm management. Chinese Journal of Chemical Engineering, 2005, 13(4): 477-483 http://www.cjche.com.cn/EN/abstract/abstract639.shtml [116] Geng Z Q, Zhu Q X, Gu X B. A fuzzy clustering-ranking algorithm and its application for alarm operating optimization in chemical processing. Process Safety Progress, 2005, 24(1): 66-75 doi: 10.1002/(ISSN)1547-5913 [117] Foong O M, Sulaiman S, Rambli D R A, Abdullah N S. ALAP: alarm prioritization system for oil refinery. In: Proceedings of the 2009 World Congress Engineering and Computer Science (WCECS 2009). San Francisco, USA: IAENG, 2009. 1012-1017 [118] Wang J D, Chen T W. Main causes of long-standing alarms and their removal by dynamic state-based alarm systems. Journal of Loss Prevention in the Process Industries, 2016, 43: 106-119 doi: 10.1016/j.jlp.2016.05.006 [119] Leitão G B P, Guedes L A, de Araújo J R S. A correlation-based approach to determining related alarms in industrial processes. In: Proceedings of the 17th Conference on Emerging Technologies and Factory Automation (ETFA). Krakow, Poland: IEEE, 2012. 1-7 [120] Yang Z J, Wang J D, Chen T W. Detection of correlated alarms based on similarity coefficients of binary data. IEEE Transactions on Automation Science and Engineering, 2013, 10(4): 1014-1025 doi: 10.1109/TASE.2013.2248000 [121] Yang Z J, Wang J D, Chen T W. On correlation analysis of bivariate alarm signals. In: Proceedings of the 2012 International Conference on Information and Automation (ICIA). Shenyang, China: IEEE, 2012. 530-535 [122] Noda M, Higuchi F, Takai T, Nishitani H. Event correlation analysis for alarm system rationalization. Asia-Pacific Journal of Chemical Engineering, 2011, 6(3): 497-502 doi: 10.1002/apj.575 [123] Nishiguchi J, Takai T. IPL 2 and 3 performance improvement method for process safety using event correlation analysis. Computers and Chemical Engineering, 2010, 34(12): 2007-2013 doi: 10.1016/j.compchemeng.2010.07.029 [124] Akatsuka S, Noda M, Sugimoto K. Similarity analysis of sequential alarms in plant operation data by using Levenshtein distance. Kagaku Kogaku Ronbunshu, 2013, 39(4): 352-358 doi: 10.1252/kakoronbunshu.39.352 [125] 赵劲松, 朱剑锋.基于数据过滤的化工过程重复报警处理策略.清华大学学报(自然科学版), 2012, 52(3): 277-281 http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201203000.htmZhao Jin-Song, Zhu Jian-Feng. Data filtering based alarm processing strategy for repeating alarms. Journal of Tsinghua University (Science and Technology, 2012, 52(3): 277-281 http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201203000.htm [126] Kondaveeti S R, Izadi I, Shah S L, Black T, Chen T W. Graphical tools for routine assessment of industrial alarm systems. Computers and Chemical Engineering, 2012, 46: 39-47 doi: 10.1016/j.compchemeng.2012.06.042 [127] Liu X W, Noda M, Nishitani H. Evaluation of plant alarm systems by behavior simulation using a virtual subject. Computers and Chemical Engineering, 2010, 34(3): 374-386 doi: 10.1016/j.compchemeng.2009.11.017 [128] Pariyani A, Seider W D, Oktem U G, Soroush M. Dynamic risk analysis using alarm databases to improve process safety and product quality: part Ⅰ--data compaction. AIChE Journal, 2012, 58(3): 812-825 doi: 10.1002/aic.v58.3 [129] Pariyani A, Seider W D, Oktem U G, Soroush M. Dynamic risk analysis using alarm databases to improve process safety and product quality: part Ⅱ--Bayesian analysis. AIChE Journal, 2012, 58(3): 826-841 doi: 10.1002/aic.v58.3 [130] Kalantarnia M, Khan F, Hawboldt K. Dynamic risk assessment using failure assessment and Bayesian theory. Journal of Loss Prevention in the Process Industries, 2009, 22(5): 600-606 doi: 10.1016/j.jlp.2009.04.006 [131] Kalantarnia M, Khan F, Hawboldt K. Modelling of BP Texas City refinery accident using dynamic risk assessment approach. Process Safety and Environmental Protection, 2010, 88(3): 191-199 doi: 10.1016/j.psep.2010.01.004 [132] Zhu J F, Zhao J S, Yang F. Dynamic risk analysis with alarm data to improve process safety using Bayesian network. In: Proceedings of the 11th World Congress on Intelligent Control and Automation (WCICA). Shenyang, China: IEEE, 2014. 461-466 [133] 高慧慧, 徐圆, 朱群雄.过程工业报警系统可视化监控技术及应用.化工学报, 2015, 66(1): 215-221 doi: 10.11949/j.issn.0438-1157.20141417Gao Hui-Hui, Xu Yuan, Zhu Qun-Xiong. Visualization monitoring techniques and applications in process industry alarm systems. CIESC Journal, 2015, 66(1): 215-221 doi: 10.11949/j.issn.0438-1157.20141417 [134] 段艳杰, 吕宜生, 张杰, 赵学亮, 王飞跃.深度学习在控制领域的研究现状与展望.自动化学报, 2016, 42(5): 643-654 http://www.aas.net.cn/CN/abstract/abstract18852.shtmlDuan Yan-Jie, Lv Yi-Sheng, Zhang Jie, Zhao Xue-Liang, Wang Fei-Yue. Deep learning for control: the state of the art and prospects. Acta Automatica Sinica, 2016, 42(5): 643-654 http://www.aas.net.cn/CN/abstract/abstract18852.shtml -

下载:

下载: