Research on Force Sensing for the End-load of Industrial Robot Based on a 6-axis Force/Torque Sensor

-

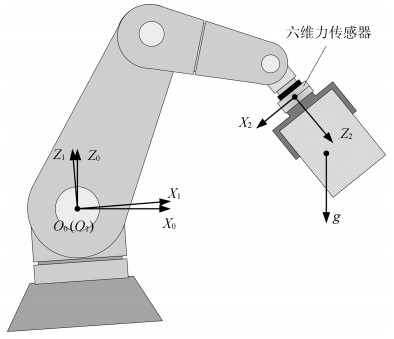

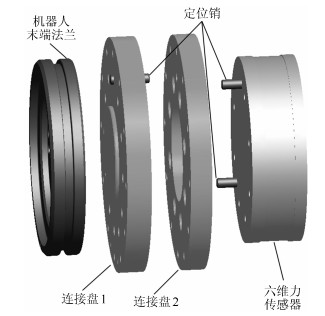

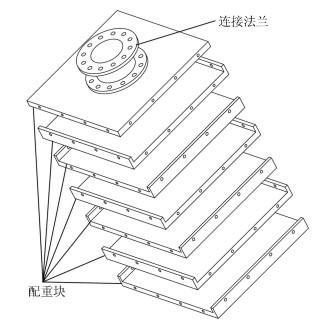

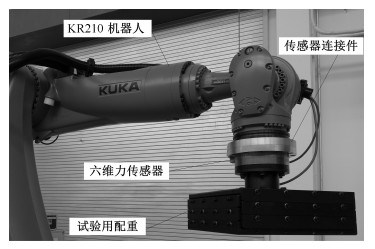

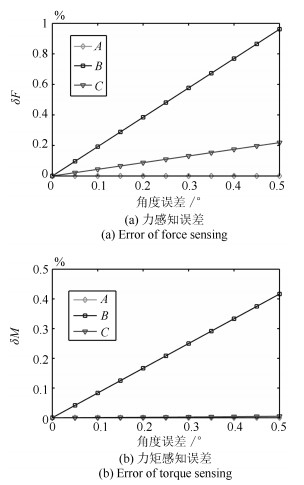

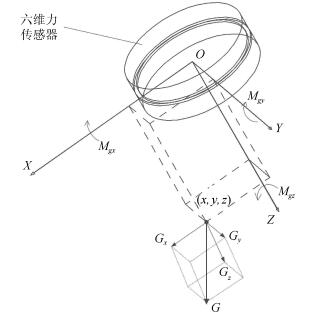

摘要: 针对工业机器人末端负载与外界环境接触力的感知需求,在机器人法兰与负载之间设置六维力传感器,并研究一套标定与计算方法,综合考虑负载重力作用、传感器零点、机器人安装倾角等因素,利用不少于3个机器人姿态下的力传感器数据,可求得传感器零点、机器人安装倾角、负载重力大小、负载重心坐标等参数,进一步可消除传感器零点及负载重力对受力感知的影响,精确得到机器人末端负载所受的外部作用力与力矩.实验得到对于重量从320N到1917N的负载,在静态条件下,感知外力的误差在负载重力的0.28%以内,感知外力矩的误差在负载对传感器力矩的0.59%以内.Abstract: Based on the 6-axis force/torque sensor mounted on the robot wrist, a estimating and computing method is studied to obtain the force between the load and nearby object. In the method, the gravity of load, bias of the sensor, installing angle of the robot are overall considered. Using the sensor data of not less than 3 robot orientations, all these parameters can be calculated, include the bias of sensor, installing angle of the robot, the gravity of the load and the coordinate of gravity center. Using the result, the influence of the load gravity and bias of sensor on the data of the sensor can be compensated, and the external force on the load can be precisely obtained. In the experiments, sensing the external force/torque for the loads from 320N to 1917N at static state, the error of force is not more than 0.28% of the load gravity, and the error of torque is not more than 0.59% of the torque caused by the load gravity.

-

Key words:

- Force sensing /

- gravity compensation /

- bias estimation /

- 6-axis force/torque sensor /

- industrial robot

-

表 1 KR210机器人性能参数

Table 1 Performance parameters of KR210

属性 额定负载 轴数 最大工作半径 重复定位精度 数值 210 kg 6 2 700 mm 0.06 mm 表 2 Omega190技术参数

Table 2 Technical parameters of Omega190

项目 $F_x$ (N) $F_y$ (N) $F_z$ (N) $T_x$ (N $\cdot$ m) $T_y$ (N $\cdot$ m) $T_z$ (N $\cdot$ m) 测量范围 ±7 200 ±7 200 ±18 000 ±1 400 ±1 400 ±1 400 分辨率 3/8 3/8 5/8 5/96 5/96 5/144 精度 0.20 % 0.19 % 0.09 % 0.33 % 0.87 % 0.30 % 表 3 机器人姿态列表

Table 3 Attitude parameters of robot

序号 $A$ (°) $B$ (°) $C$ (°) 1 -50.77 37.76 -63.44 2 0.00 60.00 0.00 3 50.77 37.76 63.44 4 60.00 0.00 90.00 5 -129.23 37.76 -116.56 6 -180.00 60.00 -180.00 7 129.23 37.76 116.56 8 120.00 0.00 90.00 表 4 加载7个配重块时的传感器数据

Table 4 Data from the sensor when 7 load blocks are mounted

序号 $F_x$ (N) $F_y$ (N) $F_z$ (N) $T_x$ (N $\cdot$ m) $T_y$ (N $\cdot$ m) $T_z$ (N $\cdot$ m) 1 1 232.1 1 339.5 -634.1 -214.3 162.2 -11.7 2 1 716.9 -3.5 -924.1 -13.4 235.6 -13.7 3 1 231.1 -1 357.8 -638.0 187.4 164.3 -15.4 4 55.4 -1 923.6 50.3 270.8 -9.2 -15.8 5 1 232.2 1 338.3 730.6 -212.7 162.8 -12.3 6 1 714.1 -3.7 1 015.6 -12.6 236.0 -14.2 7 1 232.4 -1 358.9 739.2 187.1 164.7 -15.7 8 59.5 -1 923.9 57.3 270.9 -8.5 -15.8 表 5 负载重力及机器人安装倾角计算结果

Table 5 Results of load gravity, gravity center and installing angle of robot

配重数 $G$ (N) $x$ (mm) $y$ (mm) $z$ (mm) $U$ (°) $V$ (°) 1 320.8 1.2 0.4 73.8 -0.091 -0.043 2 586.5 1.1 0.2 91.4 -0.062 -0.041 3 851.6 1.1 0.1 104.4 -0.046 -0.077 4 1 117.8 1.0 0.2 116.1 -0.028 -0.054 5 1 384.2 1.0 0.1 127.1 -0.023 -0.084 6 1 651.1 0.9 0.0 137.8 -0.039 -0.041 7 1 917.3 0.9 0.1 148.2 -0.063 -0.020 表 6 六维力传感器零点计算结果

Table 6 Results of the bias of force/torque sensor

配重数 $F_{x0}$ (N) $F_{y0}$ (N) $F_{z0}$ (N) $M_{x0}$ (N $\cdot$ m) $M_{y0}$ (N $\cdot$ m) $M_{z0}$ (N $\cdot$ m) 1 50.4 -12.3 41.8 -13.1 -9.1 -13.3 2 51.3 -10.8 42.8 -13.1 -9.3 -13.4 3 52.0 -10.2 45.2 -13.0 -9.4 -13.5 4 53.0 -9.4 46.3 -13.0 -9.5 -13.6 5 54.5 -8.1 50.6 -12.9 -9.9 -13.7 6 56.0 -9.3 50.2 -13.1 -10.0 -13.8 7 56.1 -8.7 50.2 -12.9 -10.2 -13.8 表 7 受力感知误差统计

Table 7 Statistical list of the sensing errors

配重数 $F_e$ (N) $G$ (N) $\delta_F$ (%) $M_e$ (N $\cdot$ m) $M_g$ (N $\cdot$ m) $\delta_M$ (%) 1 0.9 320.8 0.28 0.14 23.7 0.59 2 0.8 586.5 0.14 0.24 53.6 0.45 3 1.3 851.6 0.15 0.33 88.9 0.37 4 1.8 1 117.8 0.16 0.30 129.8 0.23 5 2.4 1 384.2 0.17 0.46 175.9 0.26 6 3.5 1 651.1 0.21 0.40 227.5 0.18 7 5.3 1 917.3 0.28 0.34 284.1 0.12 表 8 负载重力测量误差统计 (N)

Table 8 Statistical list of the errors on payload gravity (N)

配重数 安装重量计算值 安装重量实测值 误差 1 285.3 285.1 0.2 2 551.0 551.7 -0.7 3 816.6 817.3 -0.7 4 1 082.3 1 082.8 -0.5 5 1 348.7 1 349.4 -0.7 6 1 615.6 1 616.0 -0.4 7 1 881.8 1 880.6 1.2 表 9 参考数据随机误差

Table 9 Random error of the referred data

项目 $F_x$ (N) $F_y$ (N) $F_z$ (N) $T_x$ (N $\cdot$ m) $T_y$ (N $\cdot$ m) $T_z$ (N $\cdot$ m) 极差 $D$ 0.031 0.030 0.162 0.191 0.419 0.181 标准差 $\sigma$ 0.006 0.006 0.034 0.034 0.105 0.038 表 10 仿真受力感知误差统计

Table 10 Statistical list of errors after compensation in simulation

序号 1 2 3 4 5 6 7 $F_e$ (N) 0.6 1.1 1.6 2.1 2.7 3.2 3.7 $M_e$ (N $\cdot$ m) 0.02 0.04 0.07 0.11 0.14 0.19 0.23 -

[1] Olsson T, Haage M, Kihlman H, Johansson R, Nilsson K, Robertsson A, Björkman M, Isaksson R, Ossbahr G, Brogårdh T. Cost-efficient drilling using industrial robots with high-bandwidth force feedback. Robotics and Computer-Integrated Manufacturing, 2010, 26(1): 24-38 doi: 10.1016/j.rcim.2009.01.002 [2] Kubela T, Pochyly A, Singule V, Flekal L. Force-torque control methodology for industrial robots applied on finishing operations. Mechatronics: Recent Technological and Scientific Advances. Berlin: Springer-Verlag, 2012. 429-437 [3] 索利骞.力传感器结合机器人实现超长轴精密装配.机械研究与应用, 2013, 26(4): 1-7 http://www.cnki.com.cn/Article/CJFDTOTAL-JXYJ201304001.htmSuo Li-Qian. Long cam shaft assembly with force sensor and ABB robot. Mechanical Research & Application, 2013, 26(4): 1-7 http://www.cnki.com.cn/Article/CJFDTOTAL-JXYJ201304001.htm [4] Park J O, Kim W Y, Han S H, Park S, Ko S Y. Gravity compensation of a force/torque sensor for a bone fracture reduction system. In: Proceedings of the 13th International Conference on Control, Automation and Systems. Gwangju, Korea: IEEE, 2013. 1042-1045 [5] 魏秀权, 吴林, 高洪明, 李海超.遥控焊接工具装配力控制的重力补偿算法.焊接学报, 2009, 30(4): 109-112 http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB200904027.htmWei Xiu-Quan, Wu Lin, Gao Hong-Ming, Li Hai-Chao. Research on gravity compensation algorithm for tool-assembling with force control in remote welding. Transactions of the China Welding Institution, 2009, 30(4): 109-112 http://www.cnki.com.cn/Article/CJFDTOTAL-HJXB200904027.htm [6] 赵磊, 刘巍, 巩岩.预紧式Stewart结构六维力/力矩传感器.光学精密工程, 2011, 19(12): 2954-2962 doi: 10.3788/OPE.Zhao Lei, Liu Wei, Gong Yan. Pre-stressed six-axis force/torque sensor based on Stewart platform. Optics and Precision Engineering, 2011, 19(12): 2954-2962 doi: 10.3788/OPE. [7] Shetty B R, Ang M H Jr. Active compliance control of a PUMA 560 robot. In: Proceedings of the 1996 IEEE International Conference on Robotics and Automation. Minneapolis, Minnesota, USA: IEEE, 1996. 3720-3725 [8] Vougioukas S. Bias estimation and gravity compensation for force-torque sensors. In: Proceedings of 3rd WSEAS Symposium on Mathematical Methods and Computational Techniques in Electrical Engineering. Athens, Greece: WSEAS Press, 2001. 82-85 [9] 林君健. 基于力传感器的工业机器人主动柔顺装配系统研究[硕士学位论文], 华南理工大学, 中国, 2013Lin Jun-Jian. Research in Active Compliant Assembly System for Industrial Robot with Force Sense [Master dissertation], South China University of Technology, China, 2013 [10] 蔡明君. 基于力融合控制的遥操作机器人同构式手控器研究[硕士学位论文], 吉林大学, 中国, 2015Cai Ming-Jun. Research on Homogeneous Hand Controller based on Force Fusion Control for Telerobot [Master dissertation], Jilin University, China, 2015 [11] 张庆伟, 韩利利, 徐方, 贾凯, 邹风山.基于打磨机器人的力/位混合控制策略研究.化工自动化及仪表, 2012, 39(7): 884-887 http://www.cnki.com.cn/Article/CJFDTOTAL-HGZD201207018.htmZhang Qing-Wei, Han Li-Li, Xu Fang, Jia Kai, Zou Feng-Shan. Research on hybrid position/force control for grinding robots. Control and Instruments in Chemical Industry, 2012, 39(7): 884-887 http://www.cnki.com.cn/Article/CJFDTOTAL-HGZD201207018.htm [12] Massa D, Callegari M, Cristalli C. Manual guidance for industrial robot programming. Industrial Robot, 2015, 42(5): 457-465 doi: 10.1108/IR-11-2014-0413 [13] Du H P, Sun Y W, Feng D Y, Xu J T. Automatic robotic polishing on titanium alloy parts with compliant force/position control. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2015, 229(7): 1180-1192 doi: 10.1177/0954405414567518 [14] 张光辉, 王耀南.末端F/T传感器的重力环境下大范围柔顺控制方法.智能系统学报, 2015, 10(5): 675-683 http://www.cnki.com.cn/Article/CJFDTOTAL-ZNXT201505004.htmZhang Guang-Hui, Wang Yao-Nan. A wide range compliance control method in gravity environment based on end force/torque sensor. CAAI Transactions on Intelligent Systems, 2015, 10(5): 675-683 http://www.cnki.com.cn/Article/CJFDTOTAL-ZNXT201505004.htm [15] 杨林, 赵吉宾, 李论, 刘雷.有机玻璃研磨抛光机器人力控制研究.机械设计与制造, 2015, 2015(4): 105-107 http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201504030.htmYang Lin, Zhao Ji-Bin, Li Lun, Liu Lei. A study of grinding and polishing robot force control for plexiglass. Machinery Design & Manufacture, 2015, 2015(4): 105-107 http://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201504030.htm [16] 盛国栋, 曹其新, 潘铁文, 冷春涛, 顾凯.主从式机器人系统中力反馈的实现.机械设计与制造中国机械工程, 2015, 2015(9): 1157-1160, 1166 http://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201509005.htmSheng Guo-Dong, Cao Qi-Xin, Pan Tie-Wen, Leng Chun-Tao, Gu Kai. Implementation of force feedback in master-slave robot systems. China Mechanical Engineering, 2015, 2015(9): 1157-1160, 1166 http://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201509005.htm [17] 高强, 田凤杰, 杨林, 李静.机器人自动研抛系统平台搭建及重力补偿研究.工具技术, 2015, 49(8): 47-50 http://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201508036.htmGao Qian, Tian Feng-Jie, Yang Lin, Li Jing. Research on platform of robot automatic polishing system and gravity compensation. Tool Engineering, 2015, 49(8): 47-50 http://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201508036.htm [18] 缪新, 田威.机器人打磨系统控制技术研究.机电一体化, 2014, 20(11): 8-14 http://www.cnki.com.cn/Article/CJFDTOTAL-JDTH201411002.htmMiu Xin, Tian Wei. The control technology on robotic grinding system. Mechatronics, 2014, 20(11): 8-14 http://www.cnki.com.cn/Article/CJFDTOTAL-JDTH201411002.htm [19] 刘文波. 基于力控制方法的工业机器人磨削研究[硕士学位论文], 华南理工大学, 中国, 2014Liu Wen-Bo. Research on Industrial Robot Grinding based on Force Control [Master dissertation], South China University of Technology, China, 2014 [20] Wu Y E, Klimchik A, Caro S, Furet B, Pashkevich A. Geometric calibration of industrial robots using enhanced partial pose measurements and design of experiments. Robotics and Computer-Integrated Manufacturing, 2015, 35: 151-168 doi: 10.1016/j.rcim.2015.03.007 [21] Nubiola A, Bonev I A. Absolute robot calibration with a single telescoping ballbar. Precision Engineering, 2014, 38(3): 472-480 doi: 10.1016/j.precisioneng.2014.01.001 [22] Mosqueira G, Apetz J, Santos K M, Villani E, Suterio R, Trabasso L G. Analysis of the indoor GPS system as feedback for the robotic alignment of fuselages using laser radar measurements as comparison. Robotics and Computer-Integrated Manufacturing, 2012, 28(6): 700-709 doi: 10.1016/j.rcim.2012.03.004 [23] Slamani M, Nubiola A, Bonev I. Assessment of the positioning performance of an industrial robot. Industrial Robot: An International Journal, 2012, 39(1): 57-68 doi: 10.1108/01439911211192501 -

下载:

下载: