Industrial Process Safety Control Based on Spatio-Temporal Stable Causal Dynamic Bayesian Network

-

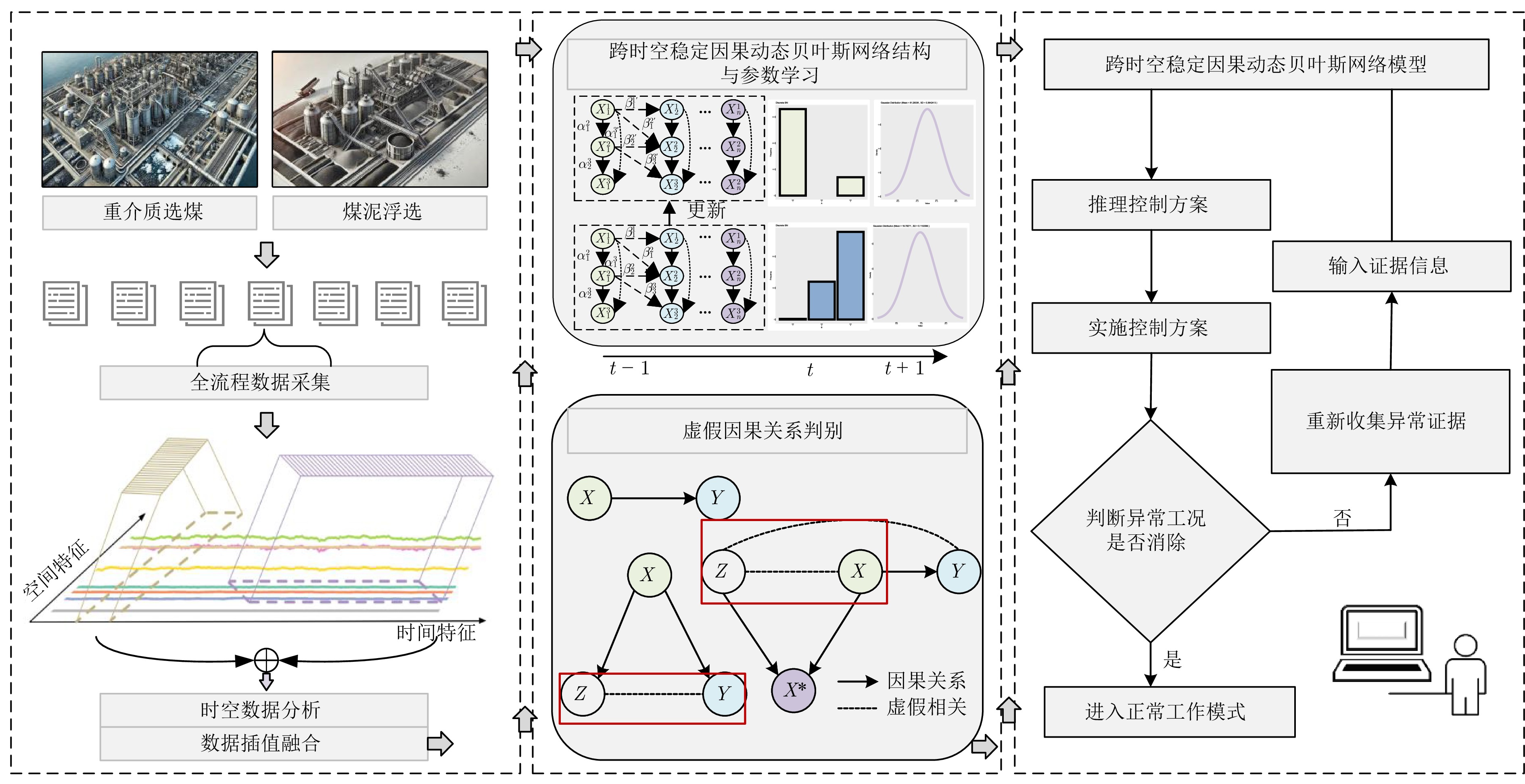

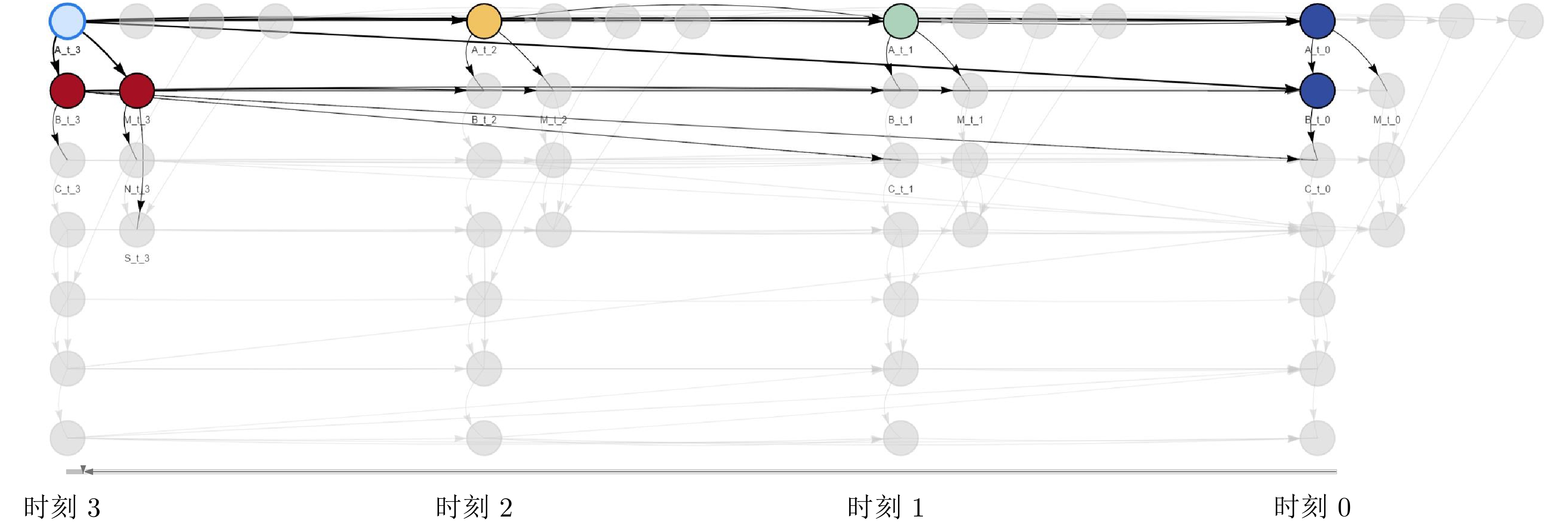

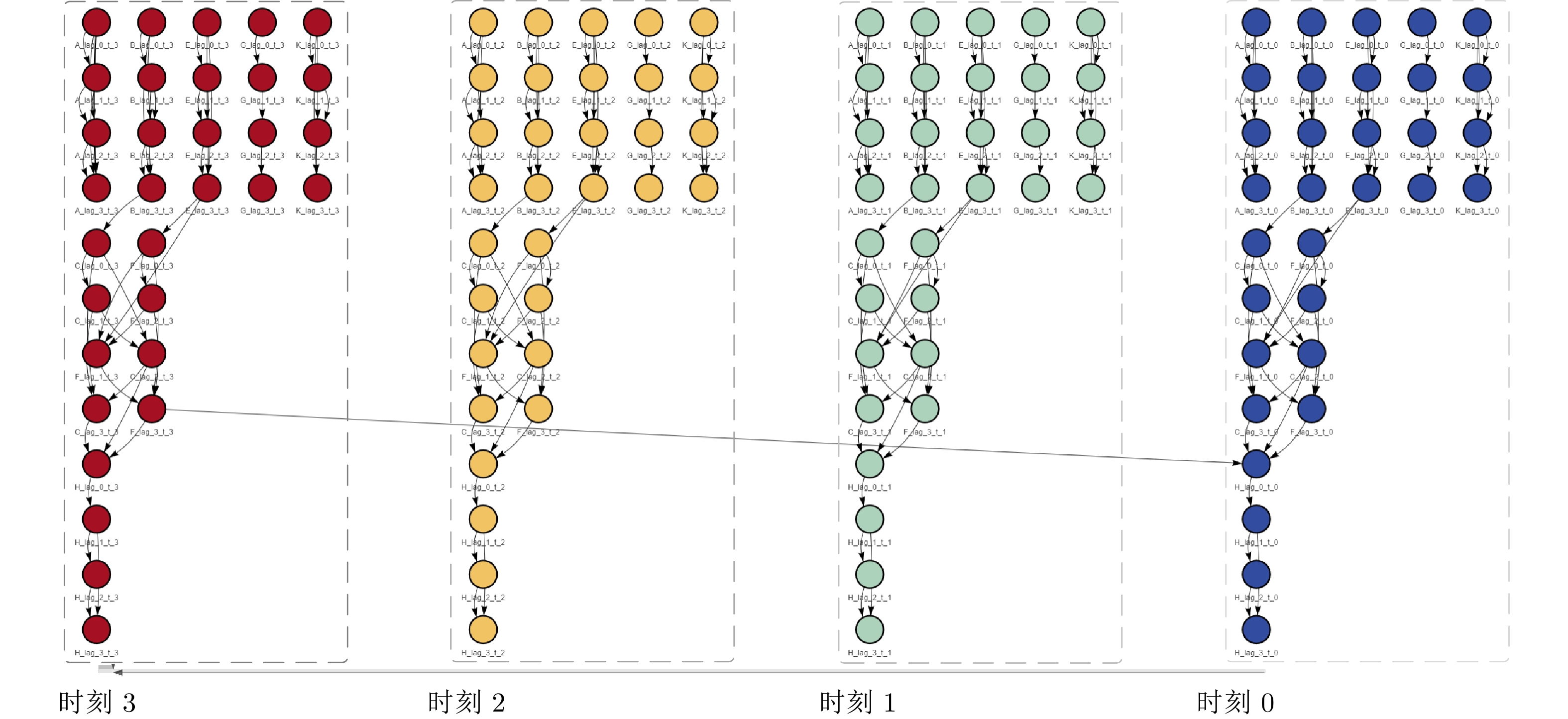

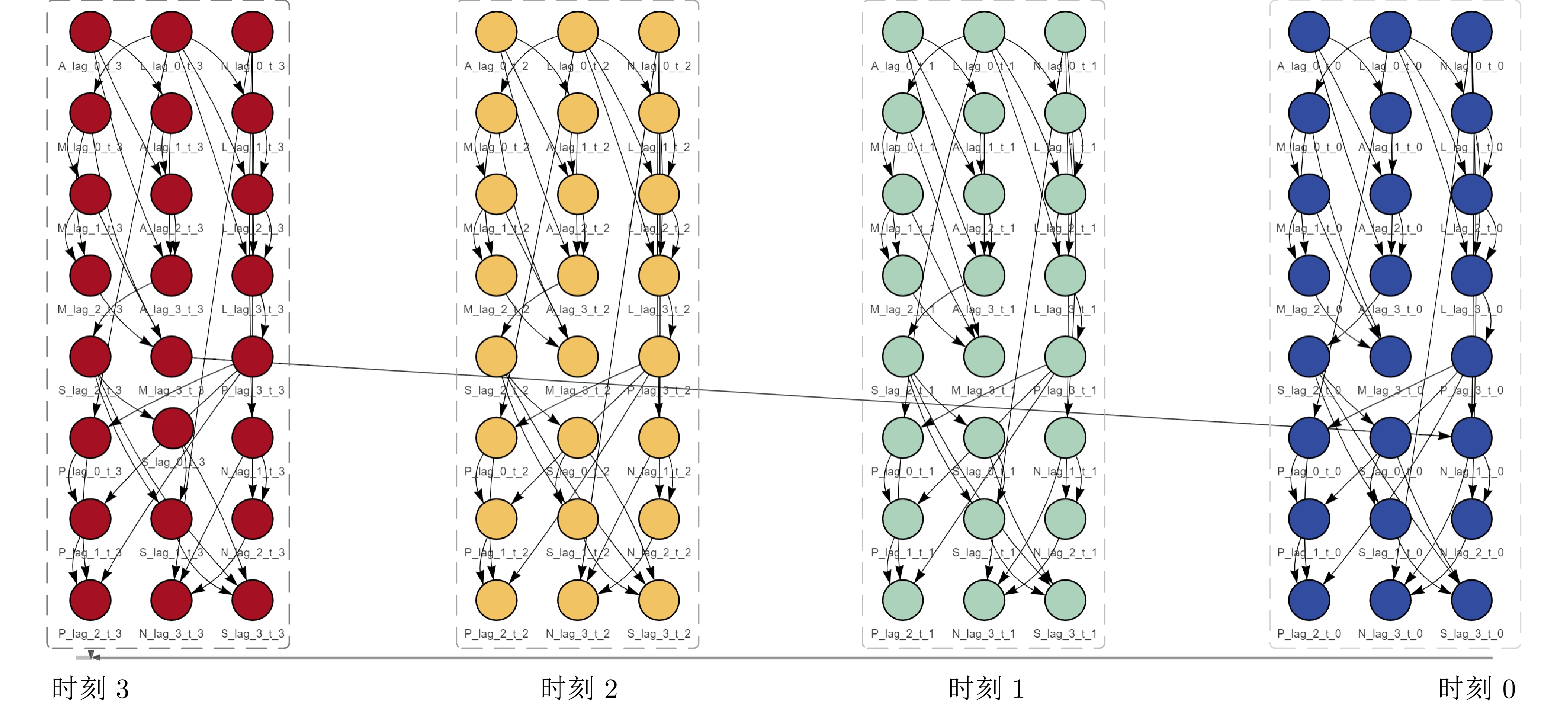

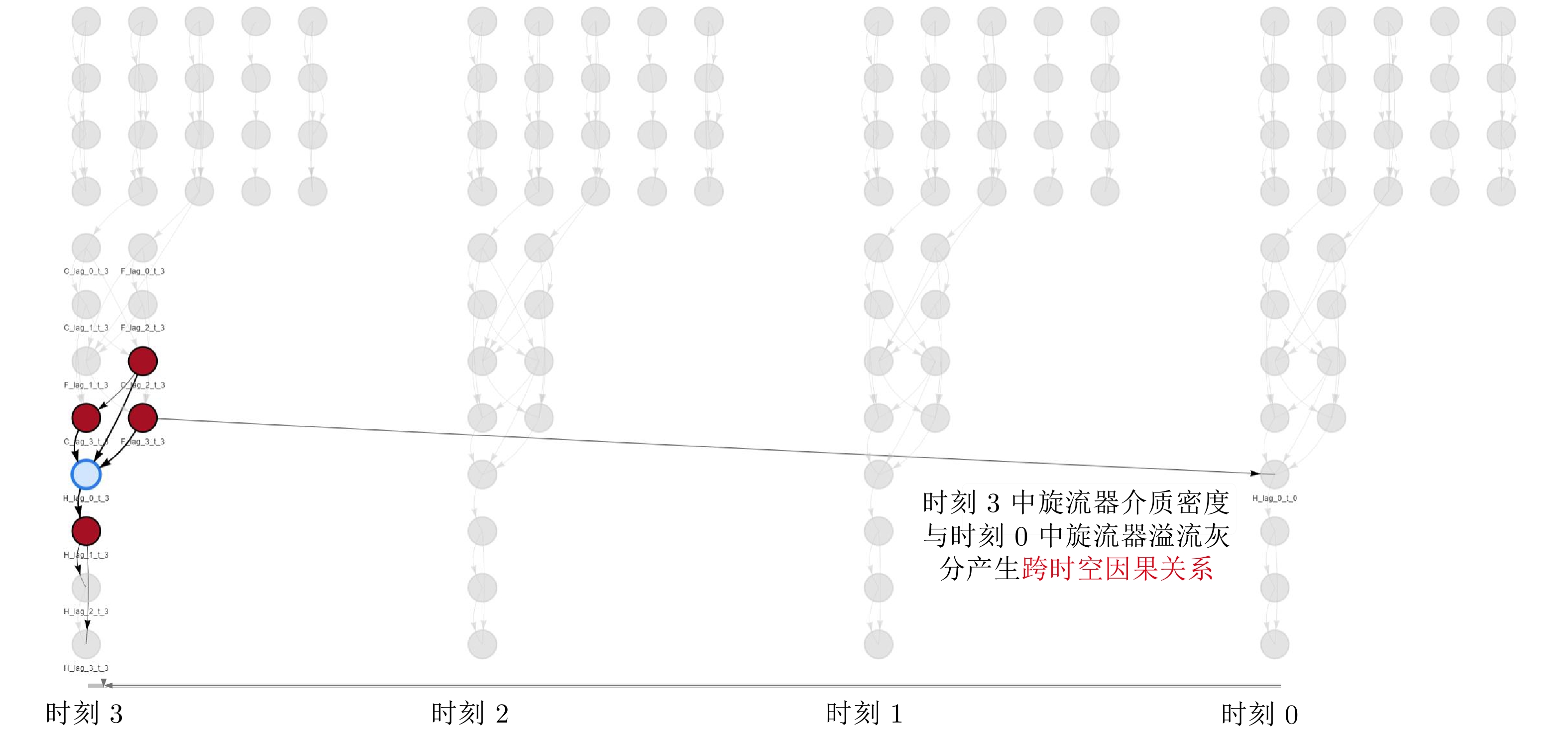

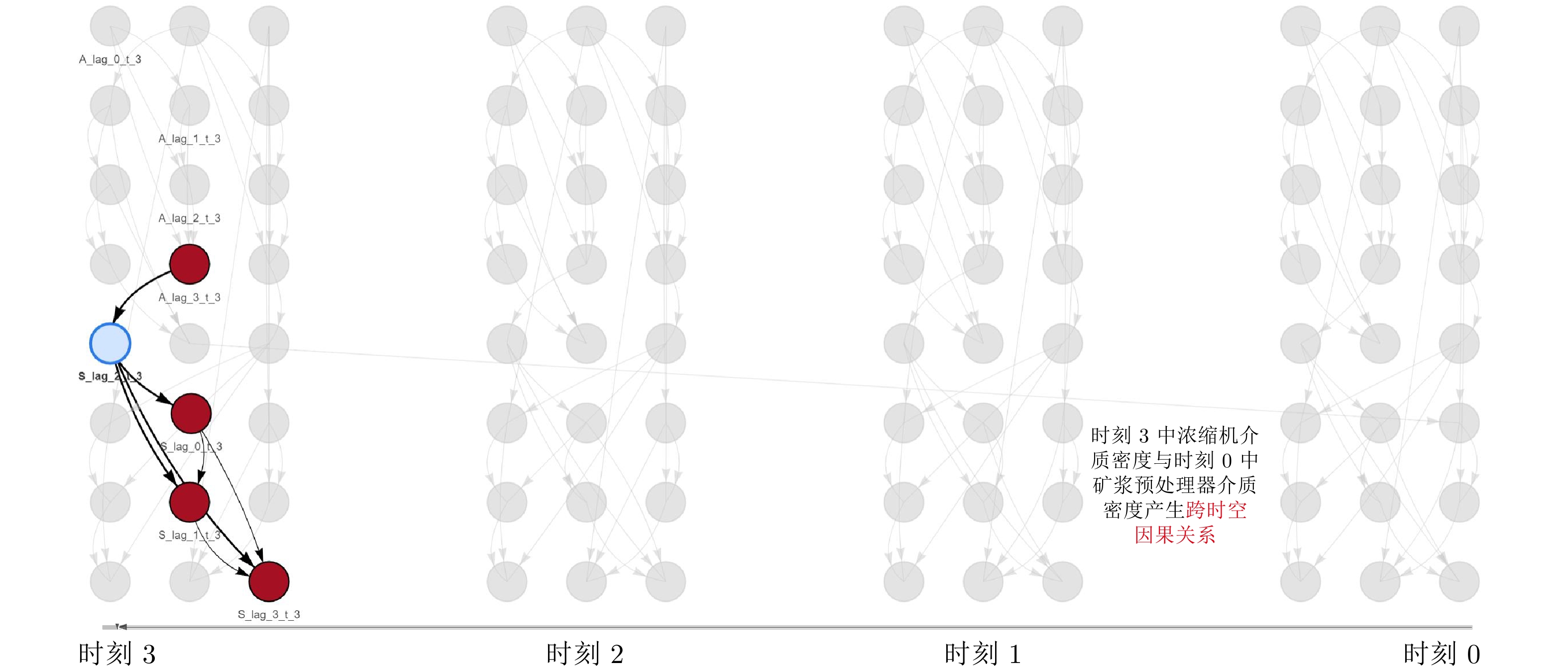

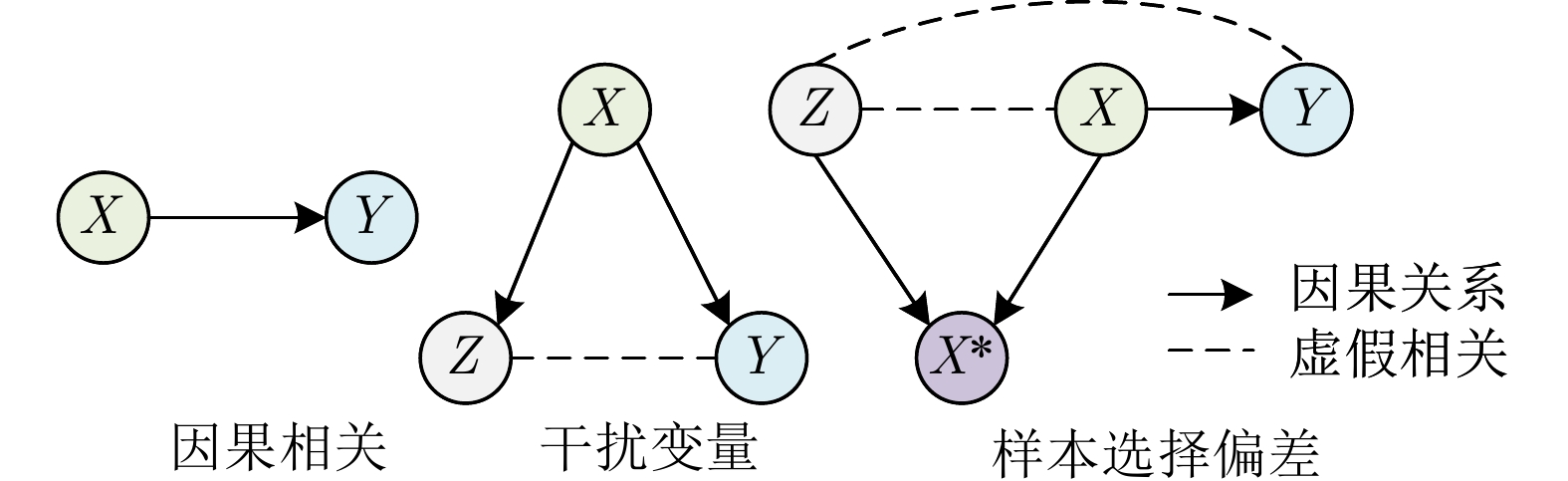

摘要: 因果关系挖掘对工业过程异常工况定位和控制方案推理至关重要. 然而, 传统的因果关系挖掘方法缺乏对时空动态变化的综合考虑, 难以有效消除虚假因果关系. 针对上述问题, 提出了基于跨时空稳定因果动态贝叶斯网络的工业过程安全控制方法. 该方法利用稳定学习(Stable learning, SL)挖掘并优化不同时空数据分布下的因果一致性特征, 确保所挖掘的因果关系在不同时空单元中具有稳定性. 在此基础上, 利用动态贝叶斯网络(Dynamic Bayesian network, DBN)引入滞后节点, 捕捉时序数据中的滞后依赖关系, 刻画因果关系的时空演化特性并利用信息熵建立因果关系筛选机制. 此外, 采用基于协变量平衡的样本重加权技术, 通过调整样本权重, 使模型能够更准确地反映理想情况下的因果特性. 最后, 选取12种典型工况案例验证了方法的有效性.Abstract: Causal relationship mining is crucial for the localization of abnormal conditions in industrial processes and the reasoning of control schemes. Nevertheless, traditional causal mining methods lack comprehensive consideration of spatio-temporal dynamic changes and struggle to effectively eliminate spurious causal relationships. To address these issues, an industrial process safety control method based on a spatio-temporal stable causal dynamic Bayesian network is proposed. This method uses stable learning (SL) to mine and optimize causally consistent features across different spatio-temporal data distributions, ensuring the stability of mined causal relationships across spatio-temporal units. Dynamic Bayesian network (DBN) are then employed to introduce lag nodes, capturing time-lagged dependencies in sequential data to characterize the spatio-temporal evolution of causal relationships. An information entropy-based causal relationship screening mechanism is established. Additionally, a covariate-balanced sample reweighting technique adjusts sample weights to enable the model to more accurately reflect ideal causal characteristics. Finally, twelve typical working condition cases validate the method's effectiveness.

-

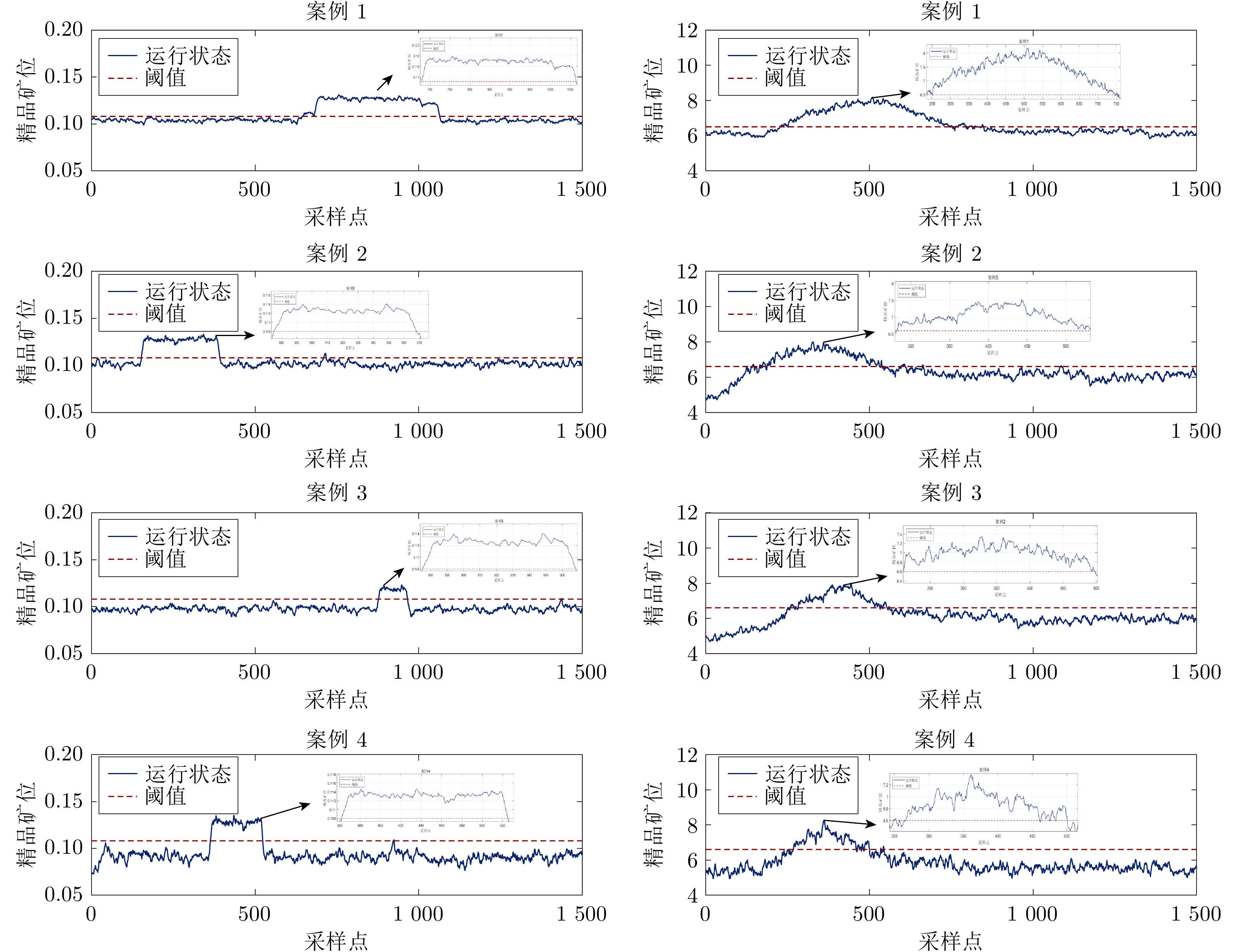

图 9 左图为实施控制方案后旋流器溢流灰分指标曲线; 右图为实施控制方案后浮选槽溢流灰分指标曲线

Fig. 9 The left figure shows the change curve of the overflow ash content index of the hydrocyclone after implementing the control scheme; the right figure shows the change curve of the overflow ash content index of the flotation cell after implementing the control scheme.

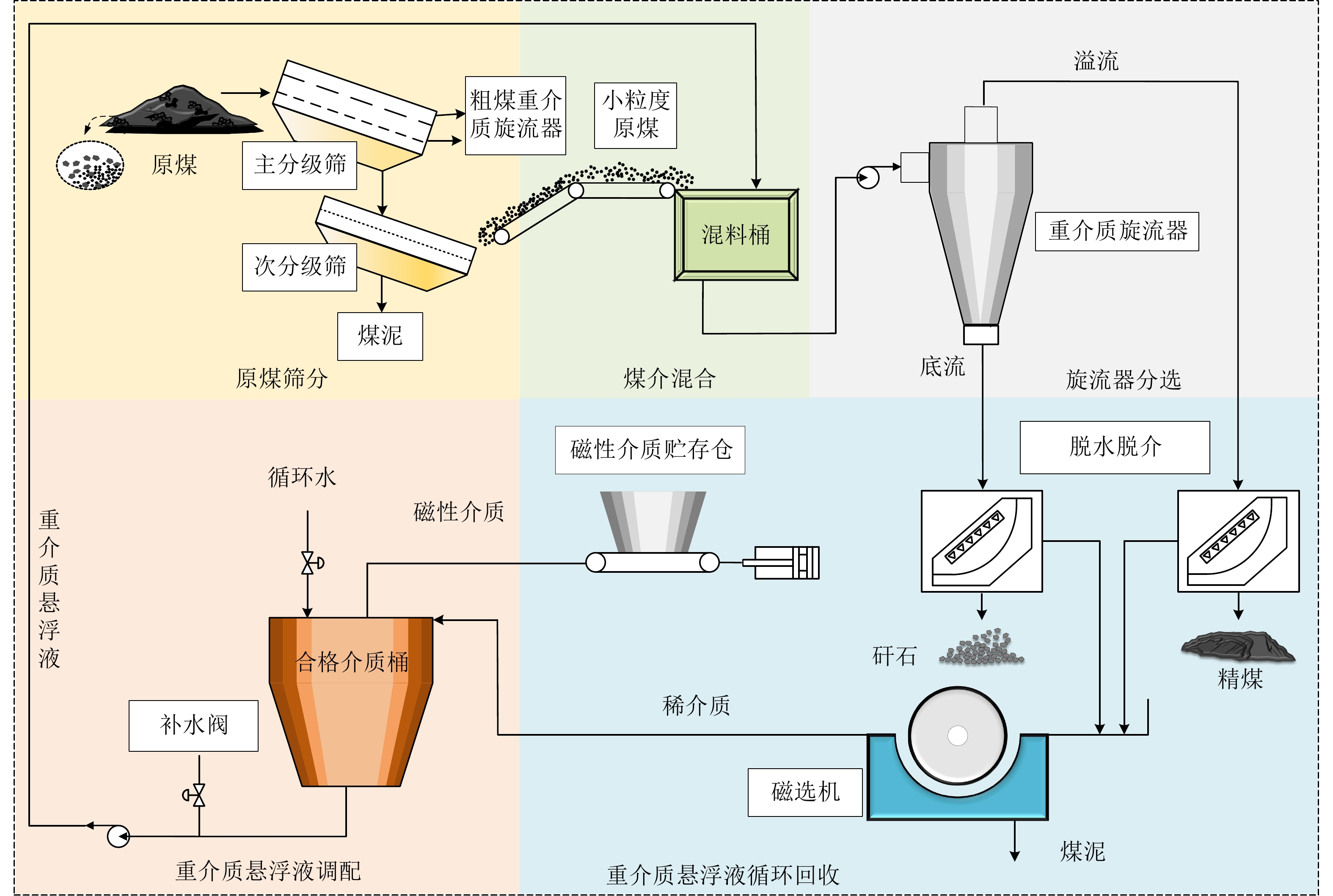

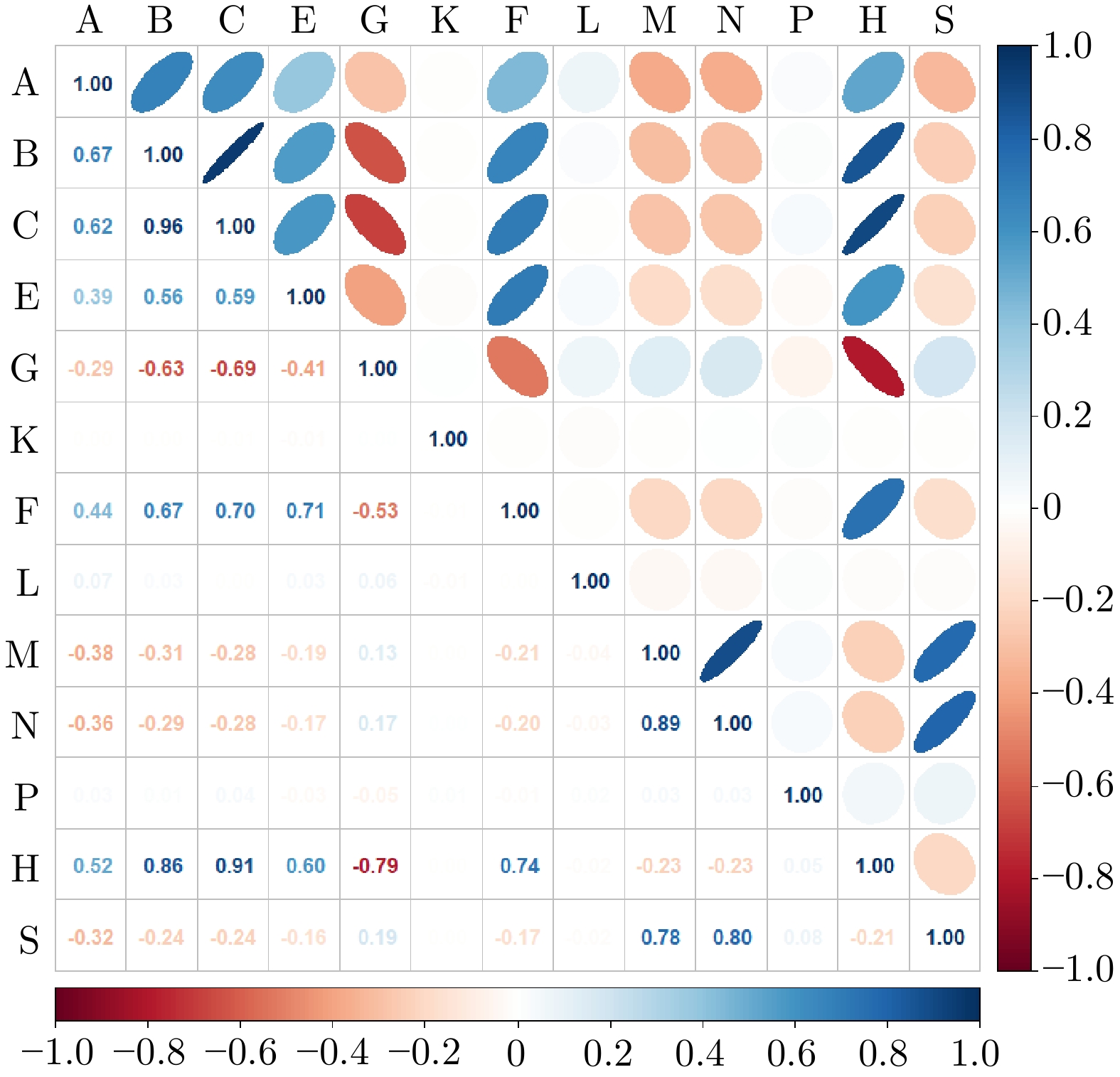

表 1 重介质选煤单元测量变量

Table 1 Measured variables of the dense medium coal preparation unit

变量含义 变量物理意义 节点标签 变量状态 双层筛 出料流量(t/h) B 1: 正常 2: 异常值偏小 3: 异常值偏大 单层筛 出料流量(t/h) C 1: 正常 2: 异常值偏小 3: 异常值偏大 混合介质桶 矿浆密度(kg/m3) E 1: 正常 2: 异常值偏小 3: 异常值偏大 旋流器 介质密度(kg/m3) F 1: 正常 2: 异常值偏小 3: 异常值偏大 合格介质桶 介质密度(kg/m3) K 1: 正常 2: 异常值偏小 3: 异常值偏大 旋流器 溢流灰分(%) H 1: 正常 2: 异常 表 2 重介质选煤单元操作变量

Table 2 Operating variables of the dense medium coal preparation unit

变量含义 变量物理意义 节点标签 变量状态 原煤仓 入煤量(t/h) A 1: 正常 2: 异常值偏小 3: 异常值偏大 旋流器 入介压力(pa) G 1: 正常 2: 异常值偏小 3: 异常值偏大 表 3 煤泥浓缩浮选单元测量变量

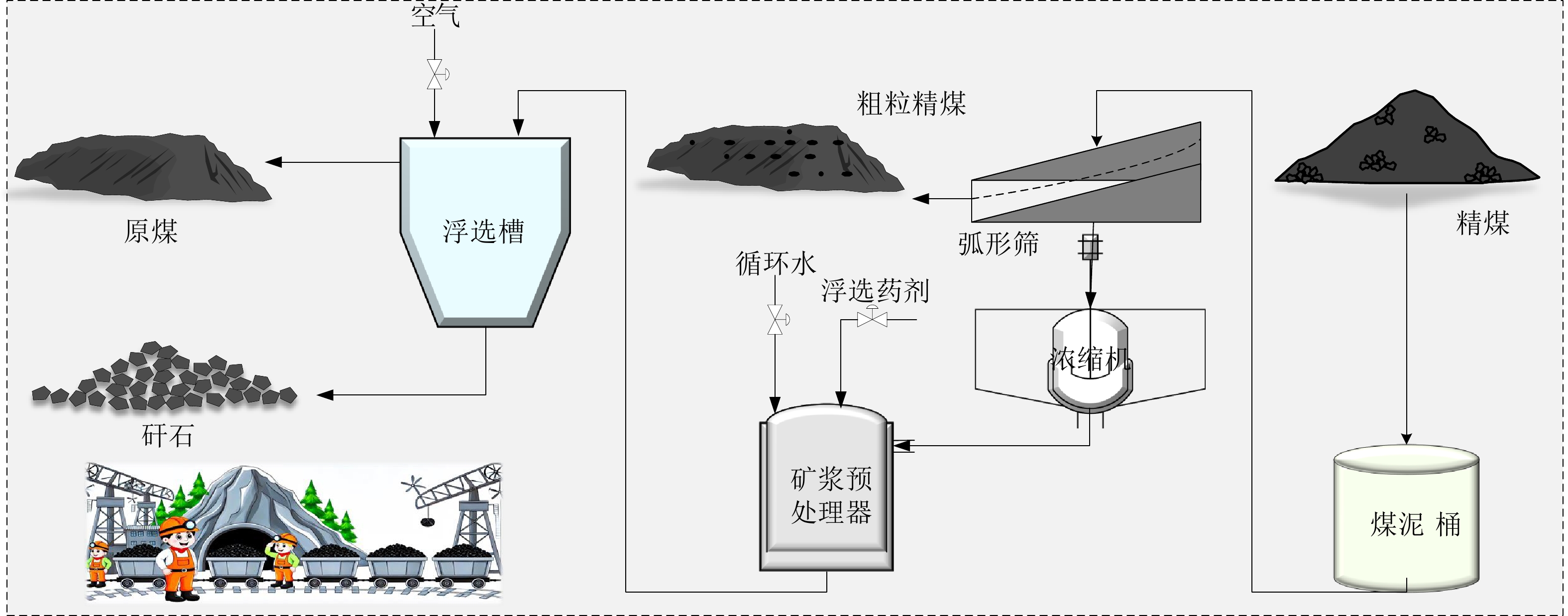

Table 3 Measured variables of the coal slurry flotation unit

变量含义 变量物理意义 节点标签 变量状态 矿浆预处理器 介质密度(kg/m3) N 1: 正常 2: 异常值偏小 3: 异常值偏大 浓缩机 介质密度(kg/m3) M 1: 正常 2: 异常值偏小 3: 异常值偏大 浮选槽 溢流灰分(%) S 1: 正常 2: 异常 表 4 煤泥浓缩浮选单元操作变量

Table 4 Operating variables of the coal slurry flotation unit

变量含义 变量物理意义 节点标签 变量状态 原煤仓 入煤量(t/h) A 1: 正常 2: 异常值偏小 3: 异常值偏大 浓缩机 底流流量(m3/h) L 1: 正常 2: 异常值偏小 3: 异常值偏大 浮选槽 搅拌速度(rad/min) P 1: 正常 2: 异常值偏小 3: 异常值偏大 表 5 重介质选煤单元格兰杰因果关系检验

Table 5 Granger causality test of the dense medium coal preparation unit

因果关系 LM统量 (Asymg) p值 LM统计量 (FS_cor) A$\rightarrow$H 6.335 0.7864 0.628 B$\rightarrow$H 14.12 0.1674 1.40 C$\rightarrow$H 31.72 0.0004 3.17 E$\rightarrow$H 644.25 $5.76 \times 10^{-132}$ 81.08 G$\rightarrow$H 27.50 0.0042 2.57 A$\rightarrow$C 201.03 $9.84 \times 10^{-38}$ 21.33 表 6 煤泥浓缩浮选单元格兰杰因果关系检验

Table 6 Granger causality test of the coal slurry flotation unit

因果关系 LM统量 (Asymg) p值 LM统计量 (FS_cor) A$\rightarrow$S 5.5096 0.0032 1.8319 L$\rightarrow$S 5.4113 0.1440 1.7949 M$\rightarrow$H 0.0488 0.9972 0.0162 N$\rightarrow$H 1.9442 0.5841 0.6455 P$\rightarrow$H 4.6752 0.1972 1.5530 M$\rightarrow$C 2.2450 0.5231 0.7469 A$\rightarrow$M 2.9028 0.4069 0.9656 P$\rightarrow$N 3.7581 0.2888 1.2497 表 7 重介质选煤单元溢流灰分H条件概率表

Table 7 Conditional probability table of overflow ash content H for dense medium coal preparation unit

C 1 2 3 F 1 2 3 1 2 3 1 2 3 H 1 0.7287 0.4662 0.1025 0.9756 0.9939 0.0682 1 0.6125 0.0221 2 0.2713 0.5338 0.8975 0.0244 0.0061 0.9318 0 0.3875 0.9779 表 8 重介质选煤单元控制变量调整策略

Table 8 Adjustment strategies for control variables in the dense medium coal preparation unit

案例 A B C E F G K 1 − − ↓ ↑ ↓ − − 2 − − ↓ ↓ − − − 3 − ↑ ↓ ↓ ↓ − − 4 − ↑ ↓ ↑ − − − 5 − ↓ ↑ − ↑ − − 6 − ↑ ↓ ↑ ↓ − − 表 9 煤泥浓缩浮选单元溢流灰分S条件概率表

Table 9 Conditional probability table of the overflow ash content S for coal slurry flotation unit

A 1 2 3 S 1 0.8516 0.4771 0.3333 2 0.1484 0.5229 0.6667 表 10 煤泥浓缩浮选单元控制变量调整策略

Table 10 Adjustment strategies for control variables in the coal slurry flotation unit

案例 A L M N P 1 ↓ ↓ ↓ − ↓ 2 ↑ − − − ↓ 3 ↑ ↑ ↑ − ↓ 4 ↓ ↑ ↑ − − 5 ↓ − − − ↓ 6 ↓ − − − ↓ -

[1] 柴天佑, 钱锋, 管晓宏, 丁进良, 堵威, 徐占伯等. 面向双碳目标的自动化和智能化理论与技术[J]. 中国科学基金, 2024, 38(04): 560−570.Chai T Y, Qian F, Guan X H, Ding J L, Du W, Xu Z B, et al. Theoryand Technologyof AutomationandIntelligencefor Dual Carbon Target (in Chinese), 2024, 38(04): 560−570. [2] Wan X, Cen L, Chen X, Xie Y, Gui, W. “Convertible Shapelet Learning With Incremental Learning Capability for Industrial Fault Diagnosis Under Shape Shift Samples,” in IEEE Transactions on Industrial Informatics, 2025, 21(4): 3356−3365. [3] Dong W, Li S, Yin X. Decentralized fault diagnosis of discrete-event systems with unreliable sensors using linear temporal logic. Science China Information Sciences, 2025, 68(1): 1−20 [4] Wu G, Zhang Y, Deng L, Zhang J, Chai T. “Cross-Modal Learning for Anomaly Detection in Complex Industrial Process: Methodology and Benchmark,” in IEEE Transactions on Circuits and Systems for Video Technology, 2025, 35(3): 2632−2645. [5] Chen X, Yang Y, Wang J. Plant‐wide processes monitoring and fault tracing based on causal graphical model. IET Control Theory & Applications, 2024, 18(17): 2322−2334 [6] Chen J, Zhao C. Multi-lag and multi-type temporal causality inference and analysis for industrial process fault diagnosis. Control Engineering Practice, 2022, 124: 105174 doi: 10.1016/j.conengprac.2022.105174 [7] Zhang X, Song C, Huang B, Zhao J. Bayesian-Based Causal Structure Inference With a Domain Knowledge Prior for Stable and Interpretable Soft Sensing. IEEE Transactions on Cybernetics, 2024, 54(10): 6081−6094 doi: 10.1109/TCYB.2024.3431636 [8] Yu F, Xiong Q, Cao L, Ya ng, F. Stable soft sensor modeling based on causality analysis. Control Engineering Practice, 2022, 122: 105109 doi: 10.1016/j.conengprac.2022.105109 [9] Zhao L, Song P, Zhao C. Causal similarity learning with multi-level predictive relation aggregation for grouped root cause diagnosis of industrial faults. Control Engineering Practice, 2025, 154: 106140 doi: 10.1016/j.conengprac.2024.106140 [10] Yu W, Zhao C, Huang B, Xie M. Intrinsic causality embedded concurrent quality and process monitoring strategy. IEEE Transactions on Industrial Electronics, 2024, 71(11): 15111−15121 doi: 10.1109/TIE.2024.3370955 [11] Jiang Q, Jiang J, Wang W, Pan C, Zhong W. Partial cross mapping based on sparse variable selection for direct fault root cause diagnosis for industrial processes. IEEE Transactions on Neural Networks and Learning Systems, 2024, 35(5): 6218−6230 doi: 10.1109/TNNLS.2023.3242361 [12] Zhang X, Song C, Zhao J, Xu Z, Deng X. Spatial-temporal causality modeling for industrial processes with a knowledge-data guided reinforcement learning. IEEE Transactions on Industrial Informatics, 2023, 20(4): 5634−5646 [13] 闫浩, 王福利, 孙钰沣, 何大阔. 基于贝叶斯网络参数迁移学习的电熔镁炉异常工况识别. 自动化学报, 2021, 47(1): 197Yan Hao, Wang Fu-Li, Sun Yu-Feng, He Da-Kuo. Abnormal condition identification based on Bayesian network parameter transfer learning for the electro-fused magnesia. Acta Automatica Sinica, 2021, 47(1): 197 [14] 毛腾, 褚菲, 王建文, 王福利. 基于分布式混合贝叶斯网络的煤泥浮选过程安全运行与产品质量一体化控制方法. 控制与决策, 2025, 40(2): 497−506Mao Teng, Chu Fei, Wang Jianwen, Wang Fuli. An integrated safe operation and product quality control method for coal slurry flotation process based on distributed hybrid Bayesian network. Control and Decision, 2025, 40(2): 497−506 [15] Cao X, Sun C and Wang X, “Threat Assessment Strategy of Human-in-the-Loop Unmanned Underwater Vehicle Under Uncertain Events,” in IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2024, 54(1), 520−532. [16] Li H, Wang F, Li H, et al. Safety control modeling method based on Bayesian network transfer learning for the thickening process of gold hydrometallurgy. Knowledge-Based Systems, 2020, 192: 105297 doi: 10.1016/j.knosys.2019.105297 [17] Zeng L, Ge Z. Bayesian network for dynamic variable structure learning and transfer modeling of probabilistic soft sensor. Journal of Process Control, 2021, 100: 20−9 doi: 10.1016/j.jprocont.2021.02.004 [18] Yang WT, Reis MS, Borodin V, Juge M, Roussy A. An interpretable unsupervised Bayesian network model for fault detection and diagnosis. Control Engineering Practice, 2022, 127: 105304 doi: 10.1016/j.conengprac.2022.105304 [19] Xia L, Zheng P, Herrera M, Liang Y, Li X, Gao, L, “Graph Embedding-Based Bayesian Network for Fault Isolation in Complex Equipment,” in IEEE Transactions on Reliability, 2024. [20] Kumari P, Bhadriraju B, Wang Q, Kwon J. S. I. A modified Bayesian network to handle cyclic loops in root cause diagnosis of process faults in the chemical process industry. Journal of Process Control, 2022, 110: 84−98 doi: 10.1016/j.jprocont.2021.12.011 [21] Zhu Y, Li Z, Wang F, Li L, “Control Sequences Generation for Testing Vehicle Extreme Operating Conditions Based on Latent Feature Space Sampling,” in IEEE Transactions on Intelligent Vehicles, 2023, 8(4), 2712−2722. [22] Stephenson T A. An introduction to Bayesian network theory and usage[J]. 2000. [23] Liu N, Hu M, Wang J, Ren Y, Tian W. “Fault detection and diagnosis using Bayesian network model combining mechanism correlation analysis and process data: Application to unmonitored root cause variables type faults. “ Process Safety and Environmental Protection, 2022, 164: 15−29 [24] Murphy K P. Dynamic bayesian networks. Probabilistic Graphical Models, M. Jordan, 2002, 7: 431 [25] Codetta-Raiteri D, Portinale L, “Dynamic Bayesian Networks for Fault Detection, Identification, and Recovery in Autonomous Spacecraft,” in IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2015, 45(1), 13−24. [26] Wang L, Zhang J, Wang H, You Q, Zhuo J, Zhang S, et al. Hydrogen leakage risk assessment of HECS based on dynamic bayesian network. International Journal of Hydrogen Energy, 2024, 78: 256−267 doi: 10.1016/j.ijhydene.2024.06.280 [27] Zhang W H., Qin J, Lu D G, Liu M, Faber M H. Quantifying the value of structural health monitoring information with measurement bias impacts in the framework of dynamic Bayesian Network. Mechanical Systems and Signal Processing,, 2023, 187: 109916 doi: 10.1016/j.ymssp.2022.109916 [28] Cui P, Athey S. Stable learning establishes some common ground between causal inference and machine learning. Nature Machine Intelligence, 2022, 4(2): 110−115 doi: 10.1038/s42256-022-00445-z [29] Shen Z, Cui P, Zhang T, Kunag K. Stable learning via sample reweighting[C]//Proceedings of the AAAI Conference on Artificial Intelligence. 2020, 34(04): 5692−5699. [30] Xu W, Yuan K, Li W, Ding W. An emerging fuzzy feature selection method using composite entropy-based uncertainty measure and data distribution. IEEE Transactions on Emerging Topics in Computational Intelligence, 2022, 7(1): 76−88 [31] Wang Z, Kuang Y, Deng J, Wang G, Ji L. Research on the intelligent control of the dense medium separation process in coal preparation plant. International Journal of Mineral Processing, 2015, 142: 46−50 doi: 10.1016/j.minpro.2015.05.001 [32] Hassanzadeh A, Safari M, Hoang D H, Khoshdast H, Albijanic B, Kowalczuk P B. Technological assessments on recent developments in fine and coarse particle flotation systems. Minerals Engineering, 2022, 180: 107509 doi: 10.1016/j.mineng.2022.107509 -

计量

- 文章访问数: 13

- HTML全文浏览量: 6

- 被引次数: 0

下载:

下载: