-

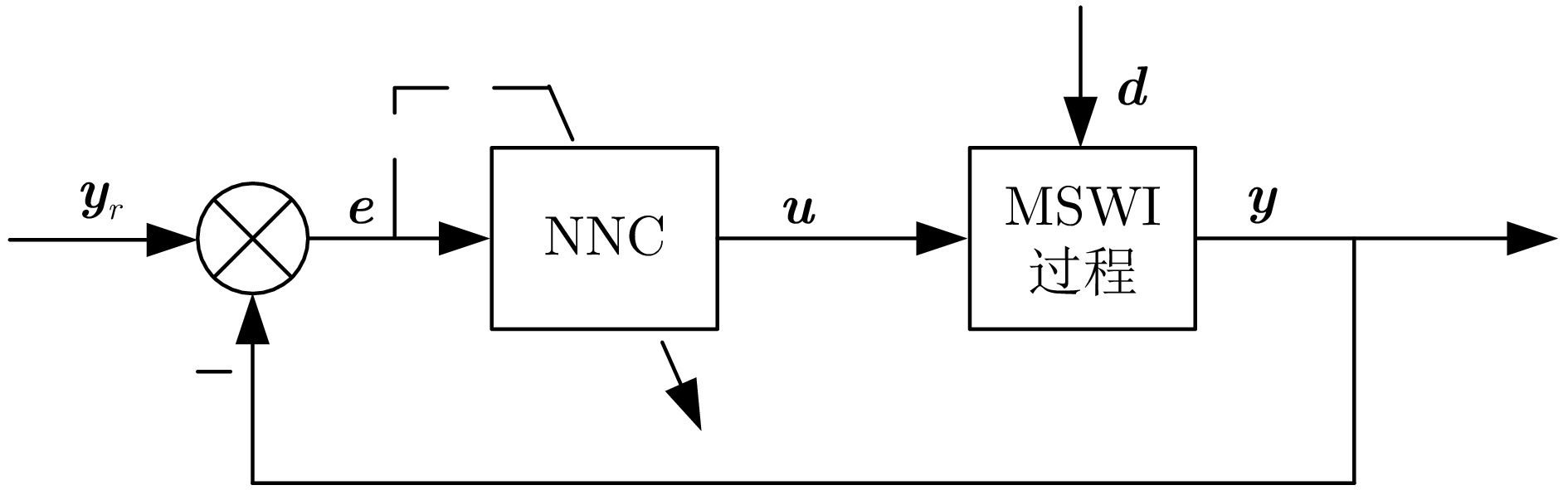

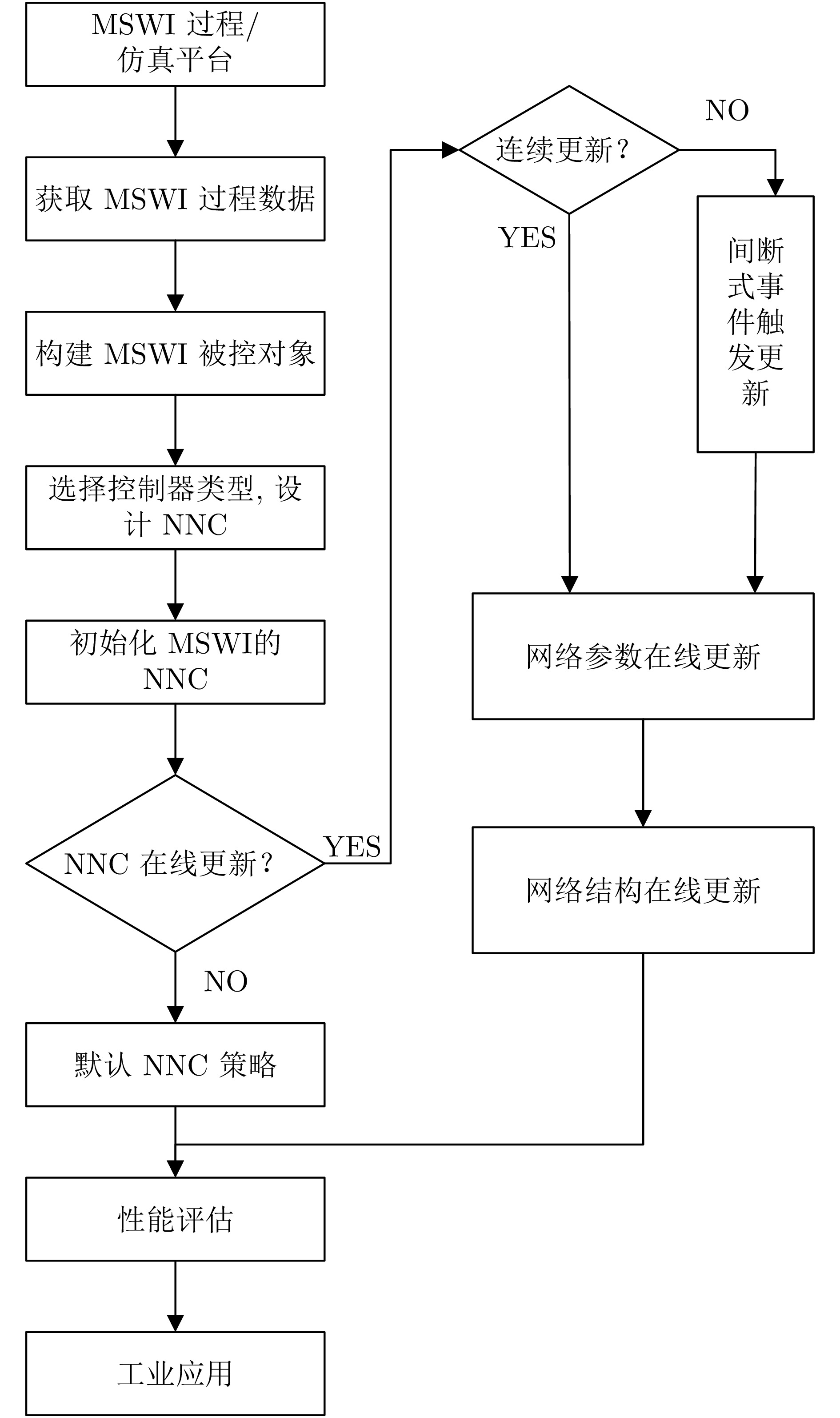

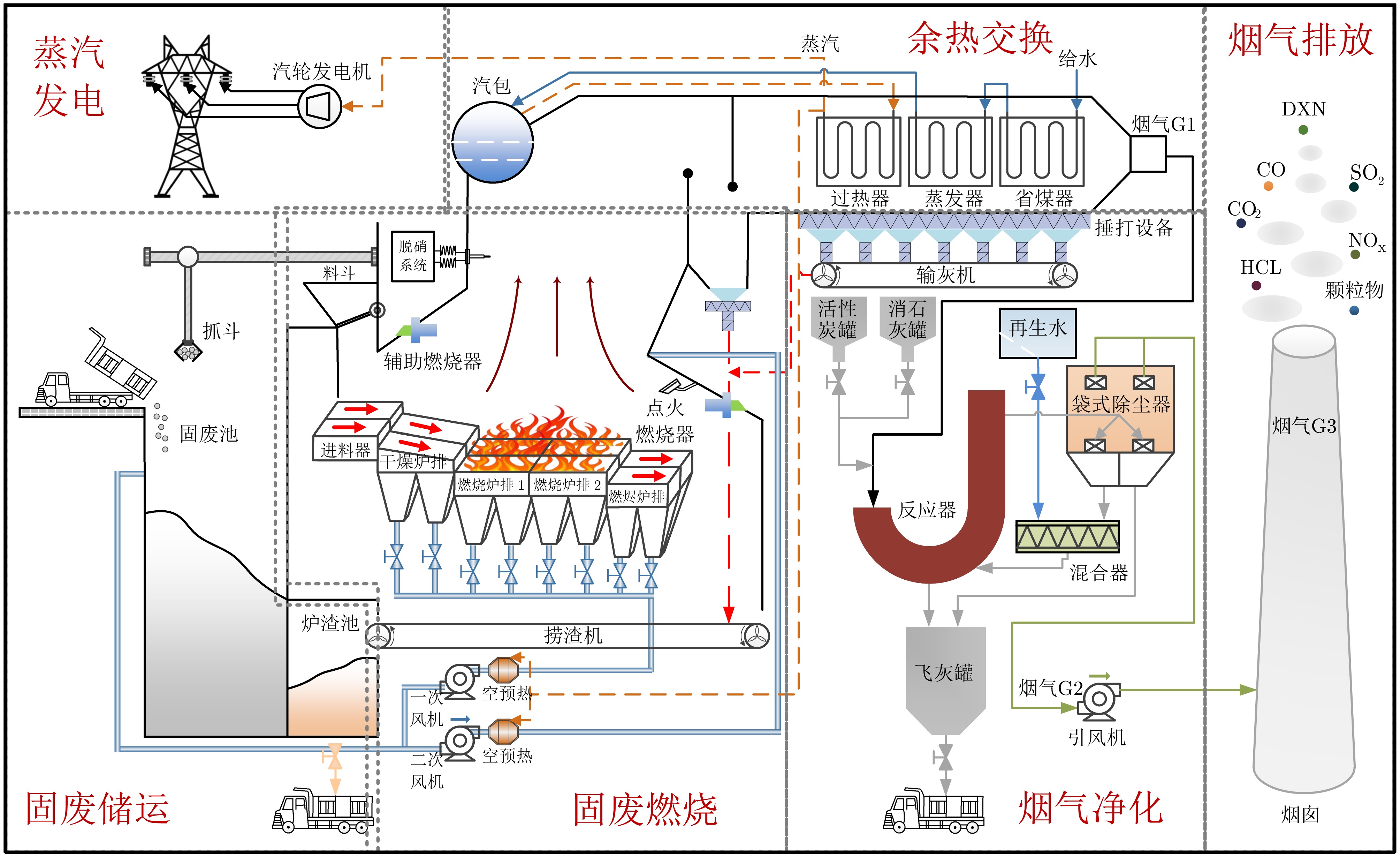

摘要: 城市固废焚烧(MSWI)已成为解决城市环境问题并实现可再生能源循环利用的主流技术, 其对应系统具有参数多、耦合性强、非线性显著等特性, 需采用先进过程控制(APC)技术以确保平稳运行. 本文进行面向MSWI过程神经网络控制(NNC)综述以弥补该领域的缺失和促进深入研究. 首先, 描述典型MSWI过程工艺, 分析其控制问题与控制目标, 明确控制复杂性, 概述NNC及其优势. 其次, 综述面向控制的机理与数据驱动焚烧炉模型. 随后, 简要分析和介绍非NNC控制器设计在MSWI过程的研究现状. 接着, 详细综述面向NNC的浅层和模糊控制器设计, 网络参数、网络结构和事件触发在线更新算法以及稳定性分析的研究现状, 并进行控制性能分析. 然后, 展望未来研究方向. 最后, 给出结论.

-

关键词:

- 城市固废焚烧(MSWI) /

- 先进过程控制(APC) /

- 神经网络控制(NNC) /

- 参数在线更新 /

- 结构自组织 /

- 事件驱动控制

Abstract: The incineration of municipal solid waste (MSWI) has emerged as a crucial technology for addressing urban environmental challenges and promoting the recycling of renewable energy. The MSWI system is characterized by numerous parameters, strong interdependencies, and significant nonlinearity, which necessitate the application of advanced process control (APC) techniques to ensure stable and efficient operation. This paper provides a comprehensive review of neural network control (NNC) applications in the MSWI process, aiming to fill existing research gaps and encourage further investigation in this field. First, the typical MSWI process is outlined, and the associated control challenges and objectives are analyzed, emphasizing the complexity of the control task. The paper then introduces neural network control (NNC) techniques, highlighting their advantages in managing such complex systems. Next, various models of incinerators used for control purposes are reviewed, including both traditional mechanistic models and data-driven approaches. A brief discussion on non-NNC controllers is also provided. The review further explores shallow and fuzzy controller designs within the context of NNC, addressing aspects such as network parameters, network structures, event-triggered online update algorithms, and stability analysis. A performance evaluation of these control strategies is included as well. Additionally, the paper outlines potential future research directions. Finally, the paper concludes with a summary of the key findings. -

表 1 面向MSWI过程控制的被控对象建模技术

Table 1 Controlled object modeling technology for MSWI process control

文献 作者/年份 方法 输入/输出及功能描述 [26] Leskens等人, 2002 系统辨识, 基于机理的动态模型 MVs: MSW入口流量、炉排速度、一次风量、二次风量; CVs: 蒸汽流量、烟气含氧量; 通过系统辨识获得模型, 确保模型能够实际应用; 动态模型有助于优化焚烧过程的运行性能 [27] Leskens等人, 2002 ARX模型 MVs: MSW入口流量、炉排速度、一次风量、二次风量; CVs: 蒸汽流量、烟气含氧量; 将模型约简应用于MIMO ARX模型, 在简化模型结构的同时保证其基本的动态特性 [28] Leskens等人, 2005 基于实验获得的动态过程模型和扰动模型 MVs: MSW入口流量、炉排速度、一次风量、二次风量; CVs: 蒸汽流量、烟气含氧量; 能够处理多变量相互作用过程、多重冲突目标和约束条件 [29] Qin等, 2008 神经网络模型 MVs: MSW入口流量、炉排速度、一次风量、二次风量; CVs: 蒸汽流量、烟气含氧量; 基于数据驱动的神经网络模型能够捕捉并描述被控对象独特的动态行为 [30] Cho等, 2017 多区域、零维建模方案 MVs: 风量、燃料供应率、蒸汽阀开度; CVs: 烟气中氧气摩尔分数、蒸汽产生率、蒸汽压力; 能够模拟真实工厂操作数据, 准确预测系统行为, 计算资源需求相对较小 [31] Wang等人, 2021 集成决策树(ensemble decision tree, EnDT)模型 MVs: 一次/二次风量、炉排速度; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 结合随机森林(Random forest, RF)和梯度提升决策树(gradient boosting decision tree, GBDT) 构建EnDT模型 [32] Riccardo等, 2022 系统辨识, 状态空间模型 MVs: 氢氧化钙的输入质量流量; CVs: 出口氯化氢浓度、布袋除尘器压降; 通过系统辨识技术验证模型, 可靠并适用于控制研究, 能够减少净化物料的消耗并优化控制性能 [33] 丁等, 2022 T-S模糊神经网络(fuzzy neural network, FNN)模型 MVs: 一次风量、二次风量、干燥炉排平均速度; CVs: 烟气含氧量、炉膛温度、蒸汽流量; 面向MSWI过程的强非线性、强耦合、大时变和高不确定等特性建立模糊模型, 为控制算法研究提供基础 [34] Chen等人, 2023 基于粒子群优化(Particle swarm optimization, PSO)的级联传递函数模型 MVs: 一次风量; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 所建模型能够反映系统在实际工况下的动态特性. [35] 王等人, 2023 RF与GBDT模型 MVs: 干燥炉排左1风量、干燥炉排速度、右1风量等37个MVs; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 面向实际工业过程构建, 提供工程化验证模型, 考虑了MSWI过程的MIMO特性 [36] Xia等人, 2023 线性回归决策树(Linear regression decision tree, LRDT)模型 MVs: 一次风量、二次风量、干燥炉排速度均值、进料器速度均值; CVs: 炉膛温度; 提高预测精度, 具有可解释性的树结构模型 [37] 王等人, 2023 多模态数据, RF和反向传播NN (Back propagation NN, BP NN) 模型 MVs: 炉排速度, 一次风量, 二次风量, 风温; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 解决多模态数据的同步问题, 提供可靠的工程化验证环境, 模拟实际工业现场进行CVs建模 [38] Wang等人, 2023 LRDT模型 MVs: 一次风量、二次风量、干燥炉排速度均值、进料器速度均值; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 通过多LRDT模型实现MIMO建模, 为优化控制提供基础 [39] Ding等, 2023 基于物料平衡和能量平衡的机理建模模型 MVs: 抓取量、推送量、干燥炉排速度、燃烧炉排1速度、燃烧炉排2速度、燃烬炉排速度、一次风量及其各分支风量、二次风量、引风机风量; CVs: 炉膛温度、烟气含氧量和蒸汽流量; 能够独立分析每个环节的内部特性, 通过计算多个子过程的输入与输出实现全流程机理建模 [40] 何等, 2023 T-SFNN模型 MVs: 一次风量、二次风压、一次风温度; CVs: 炉膛温度; 能够反映炉膛温度的变化趋势, 具有较高的拟合精度 [41] 王等人, 2024 极端梯度提升(eXtreme gradient boosting, XGBoost)串并联集成模型 MVs: 进料器均速、干燥炉排均速、一次风量二次风量、氨水注入量; CVs: 炉膛温度、蒸汽流量和烟气含氧量; 为洞悉MSWI过程的内在机理和验证智能控制与运行优化算法提供了基础 表 2 面向MSWI过程的NNC统计结果

Table 2 Statistical results of NNC for MSWI processes

文献 作者/年份 控制器类型 输入/输出/辅助参数 网络参数 网络结构 [98] 沈等, 2004 FNN控制器 输入: 加料时间、停料时间; 输出: 炉膛温度 基于系统数据

初始化控制器无 [92] 高等, 2007 BPNN控制器 输入: (未明确提及); 输出: 炉膛温度 遗传算法 无 [93] 陶等, 2008 集成NN控制器 输入: 燃烧带平均温度、冷却带平均温度、50分钟内燃烧带温度变化率和50分钟内冷却带温度变化率; 输出: 炉排转速、供风频率与处理量之比 无 无 [99] 杨等, 2011 双端输入模糊

BPNN控制器输入: (未明确提及); 输出: 炉膛温度 无 无 [106] Takaghaj等, 2012 BPNN控制器 输入: 燃油量、风量、给水量; 输出: 汽包压力、过量氧气水平状态、负载水平 Lyapunov稳定技术 无 [94] Takaghaj等, 2014 类脑神经网络控制器 输入: 燃油流量、风量、给水量; 输出: 汽包压力状态、过量氧气水平状态、蒸汽流量 Lyapunov稳定技术 无 [74] Ding等, 2023 FNN控制器 输入: 一次风量、干燥炉排速度; 输出: 炉膛温度、烟气含氧量 无 无 [100] Tian等, 2023 TSFNN控制器 输入: 一次风量、二次风量、进料机速度、干燥炉排速度、氨水注入量; 输出: 炉膛温度 无 无 [101] He等, 2023 协同自组织

TSFNN控制器输入: 二次风压、一次风温度; 输出: 炉膛温度 无 无 [102] Ding等, 2023 TSFNN控制器 输入: 一次风量、干燥炉排速度、二次风量; 输出: 炉膛温度 无 无 [103] 汤等, 2023 自适应IT2FNN

控制器输入: 一次风量、二次风量、进料器速度均值、干燥炉排速度均值、氨水注入量; 输出: 炉膛温度 无 无 [104] 丁等, 2023 FNN控制器 输入: 一次风量、干燥炉排速度、二次风量; 输出: 炉膛温度、烟气含氧量 无 无 [105] Ding等, 2023 TSFNN控制器 输入: 一次风量、干燥炉排速度; 输出: 炉膛温度、烟气含氧量 无 无 [73] Tian等, 2024 BO-ITFNN控制器 输入: 一次风量、二次风量、进料器速度均值、干燥炉排速度均值、氨水注入量; 输出: 炉膛温度 BO优化 无 [91] 游等, 2024 BPNN控制器 输入: 脱酸塔入口石灰浆流量控制阀开度; 输出/EIs: SO2和HCL排放浓度 遗传算法 遗传算法 表 3 面向MSWI过程的NNC网络参数的在线更新方法统计结果

Table 3 Statistical results of online updating method for network parameters of NNC in MSWI processes

文献 作者/年份 参数类型 损失/目标函数/ 更新算法 性能提升 [98] 沈等, 2004 隶属函数的中心和宽度、神经网络的连接权 $ {\theta ^*} = {({A^{\rm{T}}}A)^{ - 1}}{A^{\rm{T}}}y{\rm{ }} $ 递归最小二乘法 收敛速度快, 能够适应炉膛温度控制的需要 [92] 高等, 2007 NNC连接权值 $ E = \displaystyle\sum {({y_k} - {Y_k})^2} $ 反向传播算法 采用遗传算法初始化NNC; 采用反向传播算法更新网络参数 [99] 杨等, 2011 神经网络的连接权值和偏置项 $ {\theta ^*} = {({A^{\rm{T}}}A)^{ - 1}}{A^{\rm{T}}}y{\rm{ }} $ BP混合学习算法结合递归最小二乘 具有较好的过渡过程时间和超调抑制能力 [106] Takaghaj等, 2012 自适应参数、神经网络权重 $ V = \dfrac{1}{2}e_2^2 + \dfrac{1}{{{\beta _2}}}\tilde w_2^{\rm{T}}{\tilde w_2} $ 基于Lyapunov稳定的在线更新 能够在未知燃料输入导致的干扰下保持稳定 [94] Takaghaj等, 2014 自适应参数、神经网络权重 $ {V_n} = \dfrac{{e_n^{\rm{T}}{e_n}}}{2} + \dfrac{{{{\tilde p}^{\rm{T}}}\tilde p}}{{2{\beta _p}}} + \dfrac{{tr\left( {{{\tilde P}^{\rm{T}}}\tilde P} \right)}}{{2{\beta _P}}} + \dfrac{{{{\tilde w}^{\rm{T}}}\tilde w}}{{2{\beta _w}}} $ 基于Lyapunov稳定的在线更新 在PI控制无法提供满意性能的情况下, 能够实现准确的跟踪性能和稳定性 [74, 105] Ding等, 2023 高斯函数的中心、标准差、后件连接权值 $ \begin{aligned}&{{e_q}(t) = {{\left( {{r_q}(t) - {{\hat y}_q}(t)} \right)}^2}/2}\\&\qquad{E(t) = \displaystyle\sum_{q = 1}^Q \left( {{e_q}(t)} \right)}\end{aligned} $ 梯度下降法 采用经典的GD算法进行参数学习, 计算复杂度低, 学习速度快 [100] Tian等, 2023 TSFNN控制器的中心、宽度和后件参数 $ J(w) = \displaystyle\sum\limits_{t = 1}^n {(e(} t) - {e_{{\rm{ref}}}}{)^2}{\rm{ }} $ 梯度下降法 提高了炉膛温度控制的准确性和适应性; 能够快速稳定地跟踪设定值 [101] He等, 2023 中心、宽度和权值 $ V(x,\;y) = E[g(x,\;y)] = \dfrac{1}{K} \displaystyle\sum {i = 1}^K g\left( {{x_i},\;{y_i}} \right) $ 最大相关熵准则 引入相关熵削弱不确定度在控制过程中的影响; 针对不确定性问题提高了控制精度 [102] Ding等, 2023 高斯函数的中心、标准差、后件连接权值 $ E_T(t) = (r_T(t) - \hat{y}_T(t))^2/2 $ 梯度下降法 与传统的PID控制方法相比, 在控制精度和效率上具有显著提升 [103] 汤等, 2023 隶属函数的中心的上下界和宽度, 后件连接权值和偏置项 $ E(t) = \dfrac{1}{2}{\left( {\hat y(t) - {y^ * }(t)} \right)^2} = \dfrac{1}{2}e{(t)^2} $ 梯度下降法 基于GD的参数学习能够快速调整网络参数以适应新的设定值, 具有较好的自适应能力 [104] 丁等, 2023 控制器的共享参数 $ {E_c}(t) = \displaystyle\sum\limits_{q' = 1}^{Q'} {({e_{cq'}}(} t){)^2} $ 梯度下降算法 控制器能够自适应调整网络中的多类型参数; 实现对多被控变量的在线跟踪控制 [91] 游等, 2024 BPNN的权值和偏置项 $ {e_{k}} = {Y_k} - {O_k} $ 反向传播算法 应用BP算法在线更新NNC的权值和偏置项; 反应灵敏, 控制效果平缓 [73] Tian等, 2024 隶属函数的中心上下界和宽度、后件连接权值和偏置项, 以及各参数对应的学习率 $\begin{aligned}& \qquad\qquad\qquad E(t) = e^2(t)/2 \\ &F(\boldsymbol{\eta}) = \text{ISE} = \displaystyle\int_{t_0}^{t_f} e^2(t,\; \boldsymbol{\eta}) dt / (t_f - t_0) \end{aligned}$ GD算法, BO优化 GD算法进行参数学习, 提高控制器自适应能力; BO算法自适应寻优各参数学习率, 改善控制效果 表 4 面向MSWI过程的NNC网络结构的在线更新方法统计结果

Table 4 Statistical results of online updating method for network structure of NNC in MSWI processes

文献 作者/年份 评估结构更新的指标 结构更新的规则 性能提升 [74] Ding等, 2023 动态时间弯曲距离、

累积贡献增长: 当基于多任务学习评估的累积贡献满足设定阈值时; 删减: 当模糊规则之间的相似性最大且学习能力最小时; 恒定: 当神经元的动态相关性和学习能力满足特定条件时 通过自组织机制, 控制器能够实现自适应多变量控制; 提高控制精度和系统稳定性 [100] Tian等, 2023 激活强度、滑动窗口内的平均误差、规则无用率、欧氏距离 增长: 当隐藏层神经元的激活强度与误差满足特定条件时; 删减: 基于规则无用率, 当规则不再有效或有用时; 合并: 中心欧氏距离最小的两个神经元合并 通过在线学习算法, 控制器能够适应时变性; 实现对炉膛温度的准确控制, 提高控制精度和适应性 [101] He等, 2023 系统误差和激活强度 增长: 当系统误差增大且规则最大激活强度小于阈值时; 删减: 当系统误差减小且规则最小激活强度大于阈值时 可灵活地响应环境变化进行适当的结构调整; 保证模糊规则的有效性和紧凑性 [102] Ding等, 2023 信息传递强度、重要性、

网络结构敏感性增长: 当规则神经元的前向和后向信息传递强度满足设定阈值时; 删减: 当神经元的重要性和对输入的敏感性满足设定阈值时 控制器能够根据实时控制效果自适应调整网络结构, 提高了炉膛温度控制的准确性和效率 [105] 丁等, 2023 互信息、相似度、学习能力 增长: 当规则层神经元的相似度最小且对学习能力最大时; 删减: 当规则层神经元之间的相似性最大且学习能力最小时; 恒定: 当规则层神经元的相似度与学习能力处于适中水平时 控制器能够根据MSWI过程的动态变化自适应地调整网络结构; 提高控制精度和响应速度, 增强系统的稳定性和鲁棒性 表 5 面向MSWI过程的NNC事件触发在线更新方法统计结果

Table 5 Statistical results of online update method for event triggering of NNC in MSWI processes

文献 作者/年份 事件触发方式 事件触发条件 事件触发公式 性能提升 [74] Ding等, 2023 滑动窗口的误差变化率、系统误差、固定阈值 当滑动窗口的误差变化率大于阈值或系统误差大于阈值时, 触发控制器更新 $ \left\{ {\begin{aligned}&{{{\bar o}_q}(t)/\underline{o}_q(t)> {\kappa _1}{\rm{ or }}\underline{o}_q(t)/{{\bar o}_q}(t)> {\kappa _1}}\\&{\left| {{\vartheta _q}(t)} \right|> {\kappa _2},\;{\vartheta _q}(t) \in \Theta (t)}\end{aligned}} \right. $ 相比时间触发机制, 减少了53.46%; 能够有效地为控制规则提供信任时间, 避免了频繁更新对控制稳定性的影响 [101] He等, 2023 系统误差、固定阈值 当系统误差大于等于所设置固定阈值时, 触发控制器更新 $ {k_{N + 1}} = \{ |e(k)|\geq M\} $ 相比时间触发机制, 减少80%; 降低了控制器的资源消耗和控制系统的成本 [102] Ding等, 2023 系统误差、误差增量、固定阈值 当系统误差大于阈值或误差增量大于阈值时, 触发控制器更新 $ \left\{ {\begin{aligned} &{\left| {{e_{\rm{T}}}(t)} \right|> {\xi _1}}\\&{{\rm{\;or}}}\\&{\left| {{{\Delta }}{e_{\rm{T}}}(t)} \right|> {\xi _2}}\end{aligned}} \right. $ 相比时间触发机制, 更新次数减少了40%; 具有事件触发机制的控制器提供了合理的稳态控制时间, 使得控制策略更加有效 [105] Ding等, 2023 多变量系统误差、误差增量、固定阈值 当多变量系统误差大于阈值或误差增量大于阈值时, 触发控制器更新 $ \left\{ {\begin{aligned} &{\left| {{\varpi _{1,\;i}}(t(t) \in {\Omega _1}()} \right|> {\xi _1},\;{\varpi _{1,\;i}}t)}\\ &{{\rm{\;or}}}\\ &{\left| {{\varpi _{2,\;i}}(t(t) \in {\Omega _2}()} \right|> {\xi _2},\;{\varpi _{2,\;i}}t)}\end{aligned}} \right. $ 相比时间触发机制, 更新次数减少了66%; 减少了重复输入低效控制信号所引起的误差振荡问题 表 6 面向MSWI过程的NNC稳定性分析统计结果

Table 6 Statistical results of NNC stability analysis for MSWI processes

文献 作者/年份 稳定性分析内容 设计的Lyapunov函数 结论 [98] 沈等, 2004 无 无 仅从仿真层面证明系统稳定性 [92] 高等, 2007 无 无 仅从仿真层面证明系统稳定性 [99] 杨等, 2011 无 无 仅从仿真层面证明系统稳定性 [106] Takaghaj等, 2012 参数在线更新的稳定性 $ V = \dfrac{{{e^{\rm{T}}}e}}{2} + \dfrac{{{{{{\tilde \Theta }}}^{\rm{T}}}{{\tilde \Theta }}}}{{2{\beta _{{\Theta }}}}} + \dfrac{{{{\tilde G}^{\rm{T}}}\tilde G}}{{2{\beta _G}}} + \dfrac{{{{\tilde w}^{\rm{T}}}\tilde w}}{{2{\beta _w}}} $ 所设计控制系统为UUB [94] Takaghaj等, 2014 参数在线更新的稳定性 $ {V_n} = \dfrac{{e_n^{\rm{T}}{e_n}}}{2} + \dfrac{{{{\tilde p}^{\rm{T}}}\tilde p}}{{2{\beta _p}}} + \dfrac{{tr\left( {{{\tilde P}^{\rm{T}}}\tilde P} \right)}}{{2{\beta _P}}} + \dfrac{{{{\tilde w}^{\rm{T}}}\tilde w}}{{2{\beta _w}}} $ 所设计控制系统为UUB [74] Ding等, 2023 参数在线更新的稳定性;

结构在线更新的稳定性$ V_1(t) = (E(t))^2/2 $(参数更新); $ {\tilde V_2}(t) = {V_2}(t) + {\left[ { \displaystyle\sum _{q = 1}^2 \left( {{{\Delta }}\hat u_q^\prime (t) - {{\Delta }}{{\hat u}_q}(t)} \right)} \right]^2}/2 $

(结构更新); $ {\tilde V_3}(t) = {V_3}(t) + {\left[ {\displaystyle \sum _{q = 1}^2 \left( {{{\Delta }}\hat u_q^{\prime \prime }(t) - {{\Delta }}{{\hat u}_q}(t)} \right)} \right]^2}/2 $

(结构更新)当学习率满足$ 0< \eta< \dfrac{2}{{{{\left( {{\lambda _{\max }}} \right)}^2}}} $时, 系统是稳定的; 控制器在自组织

过程中, 系统是稳定的[100] Tian等, 2023 无 无 基于实际工业数据实验

证明系统稳定性[101] He等, 2023 参数在线更新的稳定性 $ V(k) = \dfrac{1}{{\sqrt {2\pi } {\sigma _g}}}\left( {1 - \exp \left( {\dfrac{{ - {e_k}^2}}{{2{\sigma _g}^2}}} \right)} \right) $ 当学习率满足$ 0< \eta< 2/{\left\| {\dfrac{{\partial {y_k}}}{{\partial {\Theta _k}}}} \right\|^2} $时, 系统是渐进稳定的 [102] Ding等, 2023 参数在线更新的稳定性;

结构在线更新的稳定性;

事件触发的稳定性$ {L_1}(t) = \dfrac{{e_{\rm{T}}^2(t)}}{2} $(参数更新);

$ {L_2}(t) = {L_1}(t) + \dfrac{{E_{m' + 1}^2(t)}}{2} $(结构更新);

$ {L_3}(t) = {L_1}(t) + \dfrac{{E_{m' - 1}^2(t)}}{2} $(结构更新);

$ {L_4}(t) = \dfrac{{\tilde e_{\rm{T}}^2(t)}}{2} $(事件触发)当学习率满足

$ 0< {\eta ^{\rm{c}}}< \dfrac{2}{{\parallel \gamma (t){\parallel ^2}}} $时,

系统是渐进稳定的[103] 汤等, 2023 参数在线更新的稳定性 $ E(t) = \dfrac{1}{2}{\left( {\hat y(t) - {y^ * }(t)} \right)^2} = \dfrac{1}{2}e{(t)^2} $ 当学习率满足$ {\psi _{}\underline{c}} + {\psi _{\bar c}} + {\psi _\sigma } + {\psi _w} + {\psi _b}< 2 $时, 系统是渐进稳定的 [104] 丁等, 2023 参数在线更新的稳定性;

结构在线更新的稳定性$ {\vartheta _1}(t) = \dfrac{1}{2}{\left( {{E^c}(t)} \right)^2} $(参数更新);

$ {\tilde \vartheta _2}(t) = {\vartheta _2}(t) + \dfrac{1}{2}{\left( {E_{m' - 1}^c(t)} \right)^2} $(结构更新);

$ {\tilde \vartheta _3}(t) = {\vartheta _3}(t) + \dfrac{1}{2}{\left( {E_{m' - 1}^c(t)} \right)^2} $(结构更新)当学习率满足$ 0< {\eta ^{\rm{c}}}< \dfrac{2}{{{{\left( {{\lambda _{\max }}} \right)}^2}}} $时, 系统是稳定和收敛的; 当采用所提的增长和删减机制时, 系统是稳定的 [105] Ding等, 2023 参数在线更新的稳定性 $ {\vartheta _1}(t) = \dfrac{{{{\left( {{E^c}(t)} \right)}^2}}}{2} $ 当学习率满足$ 0< {\eta ^{\rm{c}}}< \dfrac{2}{{{{\left( {{\lambda _{\max }}} \right)}^2}}} $时, 系统是稳定和收敛的 [73] Tian等, 2024 参数在线更新的稳定性 $ V(t) = e^2(t)/2 $ 当IT2FNN控制器采用GD在线更新参数且在假设满足的情况时, 系统是BIBO稳定的 [91] 游等, 2024 无 无 仅从仿真层面证明系统稳定性 表 7 面向MSWI过程的不同NNC的性能差异及优势

Table 7 Performance differences and advantages of different NNCs in MSWI process algorithms

文献 作者/年份 针对的控制难点 控制器类型及在线更新策略 对比方法 优势 [92] 高等, 2007 被控过程具有滞后性; 炉膛温度存在的不确定性和非线性导致其难以稳定控制 BPNN控制器;

参数更新人工控制 快速响应炉膛温度变化, 实现稳定控制, 减少人工操作的延迟和误差; 能够降低二次污染, 提高安全性和环保性 [93] 陶等, 2008 人工操作模式, 自动化程度低; 人工操作的滞后性 集成NN控制器 人工控制 通过神经网络模型进行MSWI过程的自动控制, 减少对高技能领域专家的依赖; 提高焚烧设备的运行效率和安全性 [99] 杨等, 2011 强非线性过程; 难以建立准确的EIs模型 双端输入模糊BPNN

控制器; 参数学习PID控制器;

模糊控制在温度控制方面具有过渡过程时间短、超调小的特点; 具备学习能力, 在波动剧烈的温度控制中缩短了过渡过程 [106] Takaghaj等, 2012 非线性和非最小相位特性; CO型锅炉的燃料热值未知且存在波动; 腐蚀和磨损导致系统参数发生变化, 具有不确定性 自适应NN控制器;

参数更新PID控制器 具有更高的性能、稳定性和适应性; 精确控制过剩氧气水平, 实现高效燃烧, 减少污染排放 [94] Takaghaj等, 2014 强非线性与不确定性; 控制器缺乏自适应能力, 稳定性差 类脑神经网络控制器;

参数更新PI控制器 在适应性、稳定性和跟踪性能方面均有显著提升 [74] Ding等, 2023 多变量强耦合和时变; MSW组分复杂和热值波动, 导致存在强不确定性; 过程非线性强, 控制过程不稳定 FNN控制器;

参数更新;

结构自组织;

事件触发更新模糊神经控制器;

自组织模糊控制器;

自组织FNN控制器;

模糊神经控制器在神经元的数量与其他控制器相似的情况下, 具备较好的控制效果; 具有同时响应多个被控变量的多回路解耦能力; 事件触发机制有助于长期稳定控制和避免瞬态异常值 [100] Tian等, 2023 炉膛温度受多种不确定与外部干扰因素的影响; 被控对象难以构建, EIs指标难以获取; 强非线性导致难以有效控制 自适应FNN控制器;

参数更新;

结构更新PID控制器 有效处理不确定性与扰动; 通过自适应能力应对线性, 提高了控制精度 [101] He等, 2023 过程具有不确定性, 炉膛温度控制难度大; 需要频繁更新控制器 基于事件触发的自组织FNN控制器;

参数更新;

结构自组织;

事件触发更新PID控制器;

基于RBF的自整定PID控制器;

FNN控制器控制性能显著优于PID类型控制器; 减少控制器更新次数, 降低操作成本; 提高控制精度和稳定性, 适应不确定性 [102] Ding等, 2023 数据含有异常值和噪声; 多过程变量间存在耦合, 控制规则难以推导; 外部干扰和不确定性对控制的稳定性构成挑战 鲁棒FNN控制器;

参数更新;

结构自组织;

事件触发更新多变量直接自组织FNN控制器;

自组织FNN控制器;

模糊控制器;

FNN控制器在处理不确定性和外部干扰时展现出更强的鲁棒性; 在面对数据不完善和外部干扰时, 提供了更为高效和可靠的控制方案. [103] 汤等, 2023 精准被控对象模型难以构建; 存在强不确定性与多源干扰 IT2FNN控制器;

参数更新FNN控制器;

PID控制器处理不确定性能力增强; 优化了控制性能 [104] 丁等, 2023 多变量耦合、工况漂移; 难以建立被控对象模型 自组织FNN控制器;

参数更新;

结构更新NN控制器;

自组织模糊控制器;

自组织FNN控制器;

FNN控制器具有良好的建模能力与在线控制性能; 构建多变量被控对象; 实现多变量同步控制, 提高控制精度与鲁棒性 [105] Ding等, 2023 多变量耦合、非线性和不确定性; 多变量被控对象模型难以建立; 外部干扰强烈, 影响控制稳定性 多变量FNN控制器;

参数更新;

结构自组织;

事件触发更新模糊神经控制器 构建多变量FNN模型作为被控对象; 有效降低能耗和机械磨损; 提供更好的控制效果和跟踪精度 [73] Tian等, 2024 存在MSW组分多变和设备维护等多源干扰; 在有效克服炉膛温度不确定性方面存在困难 BO的IT2FNN控制器;

基于BO的初值设计;

参数更新IT2FNN控制器;

自组织FNN控制器;

FNN控制器;

PID控制器能够有效地处理不确定性; 在面对复杂和不确定的环境时具有更好的适应性和鲁棒性 [91] 游等, 2024 传统PID控制反应时间长, 控制效果不佳 BPNN控制器;

参数更新PID控制器 在酸性气体排放控制精度上优于PID控制器 A1 文中缩略词及含义

A1 Abbreviations and their meanings

缩略词 英文全称 中文含义 MSW Municipal solid waste 城市固废 MSWI Municipal solid waste incineration 城市固废焚烧 WTE Waste-to-Energy 废物到能源 EIs Environmental indicators 环保指标 MV Manipulated variable 操纵变量 CV Controlled variable 被控变量 AV Auxiliary variables 辅助变量 ACC Automatic combustion control 自动燃烧控制 AI Artificial intelligence 人工智能 APC Advanced process control 先进过程控制 NNC Neural network control 神经网络控制 ANN Artificial neural network 人工神经网络 CEMS Continuous emission monitoring system 连续排放监测系统 DXN Dioxin 二噁英 HRGC / HRMS High-resolution gas chromatography / High-resolution mass spectrometry 高分辨气相色谱-高分辨率质谱联机法 EnDT Ensemble decision tree 集成决策树 RF Random forest 随机森林 GBDT Gradient boosting decision tree 梯度提升决策树 FNN Fuzzy neural network 模糊神经网络 PSO Particle swarm optimization 粒子群优化 LRDT Linear regression decision tree 线性回归决策树 BP Back propagation 反向传播 RBF Radial basis function 径向基函数 XGBoost eXtreme gradient boosting 极端梯度提升 IAI Industrial AI 工业人工智能 HSIC Human simulated intelligent control 仿人智能控制 FLC Fuzzy logic control 模糊逻辑控制 MPC Model predictive control 模型预测控制 LSTM Long short-term memory 长短期记忆 RWNN Random weight neural network 随机权重神经网络 IT2FNN Interval type-2 FNN 区间二型模糊神经网络 GD Gradient descent 梯度下降 SOA Seagull optimization algorithm 海鸥优化算法 BO Bayesian optimization 贝叶斯优化 RLS Recursive least squares 递归最小二乘 UUB Ultimately uniformly bounded 最终一致有界 -

[1] Gómez-Sanabria A, Kiesewetter G, Klimont Z, et al. Potential for future reductions of global GHG and air pollutants from circular waste management systems. Nature Communications, 2022, 13(1): 1−12 doi: 10.1038/s41467-021-27699-2 [2] 乔俊飞, 郭子豪, 汤健. 面向城市固废焚烧过程的二噁英排放浓度检测方法综述. 自动化学报, 2020, 46(6): 1063−1089Qiao J F, Guo Z H, Tang J. Dioxin Emission Concentration Measurement Approaches for Municipal Solid Wastes Incineration Process: A Survey. Acta Automatica Sinica, 2020, 46(6): 1063−1089 [3] 陈安, 陈晶睿, 崔晶, 范超, 韩玮. 中国31个直辖市和省会(首府)城市"垃圾围城"风险与对策研究–基于DⅡS方法的实证研究. 中国科学院院刊, 2019, 34(07): 797−806Chen A, Chen J R, Cui J, Fan C, Han W. Research on risks and countermeasures of "Cities Besieged by Waste" in China-An Empirical Analysis Based on DⅡS. Bulletin of Chinese Academy of Sciences, 2019, 34(07): 797−806 [4] 汤健, 夏恒, 余文, 乔俊飞. 城市固废焚烧过程智能优化控制研究现状与展望. 自动化学报, 2023, 49(10): 2019−2059Tang J, Xia H, Yu W, Qiao J F. Research status and prospects of intelligent optimization control for municipal solid waste incineration process. Acta Automatica Sinica, 2023, 49(10): 2019−2059 [5] Walser T, Limbach L, Brogioli R, et al. Persistence of engineered nanoparticles in a municipal solid-waste incineration plant. Nature Nanotechnology, 2012, 7(8): 520−524 doi: 10.1038/nnano.2012.64 [6] Xia H, Tang J, Aljerf L. Dioxin emission prediction based on improved deep forest regression for municipal solid waste incineration process. Chemosphere, 2022, 294: 133716 doi: 10.1016/j.chemosphere.2022.133716 [7] Baji? B, Dodi? S, Vu?urovi? D, et al. Waste to energy status in Serbia. Renewable and Sustainable Energy Reviews, 2015, 50: 1437−1444 doi: 10.1016/j.rser.2015.05.079 [8] Kalyani K, Pandey K. Waste to energy status in India: a short review. Renewable and Sustainable Energy Reviews, 2014, 31: 113−120 doi: 10.1016/j.rser.2013.11.020 [9] 生态环境部. 生活垃圾焚烧发电厂自动监测数据公开平台. 2022Ministry of Ecology and Environment. Automatic monitoring data disclosure platform for domestic waste incineration power plants. 2022 [10] Liang X, Kurniawan T, Goh H, et al. Conversion of landfilled waste-to-electricity (WTE) for energy efficiency improvement in Shenzhen (China): A strategy to contribute to resource recovery of unused methane for generating renewable energy on-site. Journal of Cleaner Production, 2022, 369: 133078 doi: 10.1016/j.jclepro.2022.133078 [11] Hunsinger H, Jay K, Vehlow J. Formation and destruction of PCDD/F inside a grate furnace. Chemosphere, 2002, 46: 1263−1272 doi: 10.1016/S0045-6535(01)00256-9 [12] Silpa K, Lisa C, Perinaz B, et al. What a waste 2.0: A global snapshot of solid waste management to 2050. Washington: Urban Development, 2018. [13] 谷琳, 何坤, 刘海威. 中国生活垃圾焚烧发电项目垃圾热值特性及其影响研究. 环境工程, 20227Gu L, He K, Liu H W. Study on waste heat value characteristics and its impact on waste incineration power generation project in China. Environmental Engineering, 20227 [14] Yamada T, Asari M, Miura T, et al. Municipal solid waste composition and food loss reduction in Kyoto city. Journal of Material Cycles and Waste Management, 2017, 19(4): 1351−1360 doi: 10.1007/s10163-017-0643-z [15] 桂卫华, 岳伟超, 谢永芳, 张红亮, 阳春华. 铝电解生产智能优化制造研究综述. 自动化学报, 2018, 44(11): 1957−1970Gui W H, Yue W C, Xie Y F, Zhang H L, Yang C H. A review of intelligent optimal manufacturing for aluminum reduction production. Acta Automatica Sinica, 2018, 44(11): 1957−1970 [16] 杜胜利, 张庆达, 曹博琦, 乔俊飞. 城市污水处理过程模型预测控制研究综述. 信息与控制, 2022, 51(01): 41−53Du S L, Zhang Q D, Cao B Q, Qiao J F. A Review of Model Predictive Control for Urban Wastewater Treatment Process. Information and Control, 2022, 51(01): 41−53 [17] Wang Y J, Huang J Q, Zhou W X, Lu F, Xu W H. Neural network-based model predictive control with fuzzy-SQP optimization for direct thrust control of turbofan engine. Chinese Journal of Aeronautics, 2022, 35(12): 59−71 doi: 10.1016/j.cja.2022.04.012 [18] Schwedersky B B, Flesch R C C, Rovea S B. Echo state networks for online, multi-step MPC relevant identification. Engineering Applications of Artificial Intelligence, 2022, 108(2022): 104596 [19] Tang J, Wang T Z, Xia H, Cui C L. An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process. Sustainability, 2024, 16(5): 2042 doi: 10.3390/su16052042 [20] El Asri R, Baxter D. Process control in municipal solid waste incinerators: survey and assessment. Waste Management and Research, 22(3): 177−185. [21] Bunsan S, Chen W Y, Chen H W, Chuang Y H, Grisdanurak N. Modeling the dioxin emission of a municipal solid waste incinerator using neural networks. Chemosphere, 2013, 92(3): 258−264 doi: 10.1016/j.chemosphere.2013.01.083 [22] Leskens M, Van't Veen P P, Van Kessel L B M, et al. Improved economic operation of mswc plants with a new model based pid control strategy. IFAC Proceedings Volumes, 2010, 43(5): 655−660 doi: 10.3182/20100705-3-BE-2011.00109 [23] 柴天佑. 自动化科学与技术发展方向. 自动化学报, 2018, 44(11): 1923−1930Chai T Y. Development directions of automation science and technology. Acta Automatica Sinica, 2018, 44(11): 1923−1930 [24] 孙备, 张斌, 阳春华, 桂卫华. 有色冶金净化过程建模与优化控制问题探讨. 自动化学报, 2017, 43(6): 880−892Sun B, Zhang B, Yang C H, Gui W H. Discussion on modeling and optimal control of nonferrous metallurgical purification process. Acta Automatica Sinica, 2017, 43(6): 880−892 [25] 刘强, 秦泗钊. 过程工业大数据建模研究展望. 自动化学报, 2016, 42(2): 161−171Liu Q, Qin S Z. Perspectives on big data modeling of process industries. Acta Automatica Sinica, 2016, 42(2): 161−171 [26] Van Kessel L B M, Leskens M, Brem G. On-Line Calorific Value Sensor and Validation of Dynamic Models Applied to Municipal Solid Waste Combustion. Journal of Process Control, 2002, 80(5): 245−255 [27] Leskens M, Van Kessel L B M, Van den Hof P M J. MIMO closed-loop identification of an MSW incinerator. Control Engineering Practice, 2002, 10(3): 315−326 doi: 10.1016/S0967-0661(01)00139-3 [28] Leskens M, Van Kessel L B M, Bosgra O H. Model predictive control as a tool for improving the process operation of MSW combustion plants. Waste Management, 2005, 25(8): 788−798 doi: 10.1016/j.wasman.2005.03.005 [29] Qin Y, Bai Y, Shen Z, et al. Design of combustion control system for MSW incineration plant, In: 2008 International Conference on Intelligent Computation Technology and Automation (ICICTA). IEEE, 2008, 1: 341−344 [30] Cho J, Kim D, Choi H, et al. Design of dynamic plant model and model-based controller for a heat recovery system with a swirling flow incinerator. Energy, 2018, 147: 1016−1029 doi: 10.1016/j.energy.2017.12.001 [31] Wang T, Tang J, Xia H. Key Controlled Variable Model of MSWI Process Based on Ensembled Decision Tree Algorithm. In: Proceedings of 2021 China Automation Congress. IEEE, 2021: 5038−5043. [32] Di Capaci R B, Fino D, Bosio B. Data-driven models for advanced control of acid gas treatment in waste-to-energy plants. IFAC-PapersOnLine, 2022, 55(7): 869−874 doi: 10.1016/j.ifacol.2022.07.554 [33] 丁海旭, 汤健, 夏恒, 乔俊飞. 基于TS-FNN的城市固废焚烧过程MIMO被控对象建模. 控制理论与应用, 2022, 39(8): 1529−1540 doi: 10.7641/CTA.2022.10524Ding H X, Tang J, Xia H, Qiao J F. Modeling of MIMO controlled object in municipal solid waste incineration process based on TS-FNN. Control Theory and Applications, 2022, 39(8): 1529−1540 doi: 10.7641/CTA.2022.10524 [34] Chen J K, Tang J, Xia H, Wang D D, Wang T Z, Xu W. Cascade transfer function models of MSWI process based on weight adaptive particle swarm optimization. In: Proceedings of 2021 China Automation Congress. IEEE, 2021: 5553−5558. [35] 王天峥, 汤健, 夏恒, 乔俊飞. 城市固废焚烧过程的回路控制半实物仿真平台. 系统仿真学报, 2023, 35(2): 241−253Wang T Z, Tang J, Xia H, Qiao J F. Hardware-in-the-loop simulation platform of loop control for municipal solid waste incineration process. Journal of System Simulation, 2023, 35(2): 241−253 [36] Xia H, Tang J, Wang T, Tian H, Cui C, Xu W. Interpretable controlled object model of furnace temperature for MSWI process based on a novel linear regression decision tree. In: Proceedings of 2023 35th Chinese Control and Decision Conference (CCDC). IEEE, 2023: 325−330. [37] 王天峥, 汤健, 夏恒, 潘晓彤, 乔俊飞, 刘溪芷. 多模态数据驱动的城市固废焚烧过程验证平台设计与实现. 中国电机工程学报, 20221−12Wang T Z, Tang J, Xia H, Pan X T, Qiao J F, Liu X Z. Design and implementation of multimodal data-driven verification platform for urban solid waste incineration process. Proceedings of the CSEE, 20221−12 [38] Wang T, Tang J, Xia H, et al. Multiple Input Multiple Output Control Method Based on Single Neuron Adaptive PID for Municipal Solid Waste Incineration Process. In: Proceedings of 2023 35th Chinese Control and Decision Conference (CCDC). IEEE, 2023: 331−336. [39] Ding H X, Tang J, Qiao J. Dynamic modeling of multi-input and multi-output controlled object for municipal solid waste incineration process. Applied Energy, 2023, 339: 120982 doi: 10.1016/j.apenergy.2023.120982 [40] 何海军, 蒙西, 汤健, 等. 城市固废焚烧过程炉膛温度建模与控制研究. 控制工程, 2023, 30(10): 1852−1862He H J, Meng X, Tang J. Modeling and Control of Furnace Temperature in Urban Solid Waste Incineration Process. Control Engineering, 2023, 30(10): 1852−1862 [41] 王天峥, 汤健, 夏恒, 乔俊飞. 基于XGBoost串并联集成的数据驱动MSWI全流程模型. 计算机集成制造系统, 20241−20Wang T Z, Tang J, Xia H, Qiao J F. Data driven modeling of MSWI whole process based on XGBoost serial and parallel ensemble. Computer Integrated Manufacturing Systems, 20241−20 [42] Wang J, Peng Z, Wang X, et al. Deep fuzzy cognitive maps for interpretable multivariate time series prediction. IEEE transactions on fuzzy systems, 2020, 29(9): 2647−2660 [43] Zhang H, Zhou A, Chen Q, et al. SR-Forest: a genetic programming based heterogeneous ensemble learning method. IEEE Transactions on Evolutionary Computation, 2023. [44] De Campos Souza P V, Dragoni M. IFNN: Enhanced Interpretability and Optimization in FNN via Adam Algorithm. Information Sciences, 2024121002 [45] Fei J, Xie J. Self-Evolving Hermite Fuzzy Neural Fractional-Order Sliding Mode Control of MEMS Gyroscope. IEEE Transactions on Automation Science and Engineering, 2024. [46] Carrasco F, Llauró X, Poch M. A methodological approach to knowledge-based control and its application to a municipal solid waste incineration plant. Combustion Science and Technology, 2006, 178(4): 685−705 doi: 10.1080/00102200500248243 [47] Ju Y. Intelligent Optimization Control Strategy for Secondary Pollution of Flue Gas in Municipal Solid Waste Incineration. Wireless Communications and Mobile Computing, 2022, 2022: Article ID 123456 [48] Ni Y M, Li L. Garbage incineration and intelligent fusion strategy of secondary pollution control. In: Proceedings of Advanced Materials Research. Trans Tech Publications Ltd, 2014, 853: 323−328. [49] 肖前军, 许虎. 生活垃圾焚烧炉燃烧过程温度的仿人智能控制. 智能系统学报, 2015, 10(6): 881−885 doi: 10.11992/tis.201507039Xiao Q J, Xu H. Algorithm for human-simulated intelligent temperature control of incinerator combustion process of urban household garbage. CAAI Transactions on Intelligent Systems, 2015, 10(6): 881−885 doi: 10.11992/tis.201507039 [50] 巫茜. 采用PSO改进的智能算法在焚烧污染控制中的应用. 重庆理工大学学报(自然科学), 2018, 32(12): 133−138Wu Q. Application study of PSO improving based intelligent algorithm in incineration pollution control. Journal of Chongqing University of Technology (Natural Science), 2018, 32(12): 133−138 [51] 钱大群, 孙振飞. 一个垃圾焚烧智能控制系统. 信息与控制, 1993, 22(6): 374−377Qian D Q, Sun Z F. A waste incineration intelligent control system. Information and Control, 1993, 22(6): 374−377 [52] 沈凯, 陆继东, 昌鹏, 李正华, 刘刚. 模糊自适应方法在垃圾焚烧炉温度控制系统中的应用. 动力工程, 2004, 24(3): 366−369Shen K, Lu J D, Chang P, Li Z H, Liu G. Application of adaptive fuzzy control method in combustion temperature process control system of incinerator. Journal of Chinese Society of Power Engineering, 2004, 24(3): 366−369 [53] Shen K, Lu J D, Li Z H, Liu G. An adaptive fuzzy approach for the incineration temperature control process. Fuel, 2005, 84(9): 1144−1150 doi: 10.1016/j.fuel.2004.06.042 [54] 昌鹏, 陆继东, 沈凯, 李正华. 垃圾焚烧炉炉温加权因子自适应控制方法的研究. 锅炉技术, 2004, 35(6): 77−81 doi: 10.3969/j.issn.1672-4763.2004.06.020Chang P, Lu J D, Shen K, Li Z H. Research on weight factor adaptive control system of incinerator temperature. Boiler Technology, 2004, 35(6): 77−81 doi: 10.3969/j.issn.1672-4763.2004.06.020 [55] Cervantes J, Yu W, Salazar S, et al. Time-varying output-based Takagi-Sugeno fuzzy controller of uncertain nonlinear systems. International Journal of Systems Science, 2020, 51(9): 1495−1510 doi: 10.1080/00207721.2020.1723732 [56] Han H G, Sun C, Wu X L, et al. Training fuzzy neural network via multiobjective optimization for nonlinear systems identification. IEEE Transactions on Fuzzy Systems, 2021, 30(9): 3574−3588 [57] 何海军, 蒙西, 汤健. 基于ET–RBF–PID的城市固废焚烧过程炉膛温度控制方法. 控制理论与应用, 2022, 39(12): 2262−2273He H J, Meng X, Tang J. A furnace temperature control method for urban solid waste incineration process based on ET-RBF-PID. Control Theory and Applications, 2022, 39(12): 2262−2273 [58] 代爽, 张伟, 张先鹤. 垃圾焚烧炉燃烧系统的模糊控制与仿真. 科学技术创新, 2019(22): 21−22 doi: 10.3969/j.issn.1673-1328.2019.22.011Dai S, Zhang W, Zhang X H. Fuzzy control and simulation of combustion system in waste incineration furnaces. Science and Technology Innovation, 2019(22): 21−22 doi: 10.3969/j.issn.1673-1328.2019.22.011 [59] Wang T Z, Tang J, Xia H. Multiple Input Multiple Output Control Method Based on Single Neuron Adaptive PID for Municipal Solid Waste Incineration Process. In: Proceedings of 2023 35th Chinese Control and Decision Conference (CCDC). IEEE, 2023: 331−336. [60] Ding H, Tang J, Qiao J. MIMO modeling and multi-loop control based on neural network for municipal solid waste incineration. Control Engineering Practice, 2022, 127: 105280 doi: 10.1016/j.conengprac.2022.105280 [61] Leskens M, Van Kessel L B M, Van den Hof P M J, Bosgra O H. Nonlinear model predictive control with moving horizon state and disturbance estimation–with application to MSW combustion. IFAC Proceedings Volumes, 2005, 38(1): 291−296 [62] Leskens M, Van Der Linden R J P, Van Kessel R L, Bosgra O H. Nonlinear model predictive control of municipal solid waste combustion plants. In: Proceedings of International Workshop on Assessment and Future Directions of NMPC. Pavia, Italy, 2008. [63] Qiao J, Sun J, Meng X. Event-triggered adaptive model predictive control of oxygen content for municipal solid waste incineration process. IEEE Transactions on Automation Science and Engineering, 2022. [64] Sun J, Meng X, Qiao J. Data-driven optimal control for municipal solid waste incineration process. IEEE Transactions on Industrial Informatics, 2023. [65] Wang R, Yan A. R-RWNN based Model Predictive Control for NOx Emissions of MSWI Process. In: Proceedings of 2023 CAA Symposium on Fault Detection, Supervision and Safety for Technical Processes (SAFEPROCESS). IEEE, 2023: 1−5. [66] 胡开成, 严爱军, 王殿辉. 城市固废焚烧过程炉温非线性模型预测控制. 控制理论与应用, 20241−9 doi: 10.7641/CTA.2022.20145Hu K C, Yan A J, Wang D H. Nonlinear model predictive control of furnace temperature for a municipal solid waste incineration process. Control Theory and Applications, 20241−9 doi: 10.7641/CTA.2022.20145 [67] 孙剑, 蒙西, 乔俊飞. 数据驱动的城市固废焚烧过程烟气含氧量预测控制. 控制理论与应用, 20241−12 doi: 10.7641/CTA.2022.20145Sun J, Meng X, Qiao J F. Data-driven predictive control of oxygen content in flue gas during the municipal solid waste incineration process. Control Theory and Applications, 20241−12 doi: 10.7641/CTA.2022.20145 [68] 蒙西, 彭亚惠, 孙子健, 等. 城市固废焚烧过程炉膛温度模型预测控制. 第34届中国过程控制会议论文集, 2023: 1Meng X, Peng Y H, Sun Z J, et al. Model Predictive Control of Furnace Temperature for Municipal Solid Waste Incineration Process. In: Proceedings of the 34th Chinese Process Control Conference (CPCC), 2023: 1. [69] 汤健, 王博康, 夏恒, 王天峥, 乔俊飞. 基于自组织IT2FNN的城市固废焚烧过程炉膛温度预测控制. 北京工业大学学报, 20241−11 doi: 10.11936/bjutxb2022030018Tang J, Wang B K, Xia H, Wang T Z, Qiao J F. Furnace temperature prediction control based on self-organizing IT2FNN for municipal solid waste incineration process. Journal of Beijing University of Technology, 20241−11 doi: 10.11936/bjutxb2022030018 [70] 孙剑, 蒙西, 乔俊飞. 城市固废焚烧过程烟气含氧量自适应预测控制. 自动化学报, 2022, 48(x): 1−13Sun J, Meng X, Qiao J F. Adaptive predictive control of oxygen content in flue gas for municipal solid waste incineration process. Acta Automatica Sinica, 2022, 48(x): 1−13 [71] Wang B, Tang J, Xia H, et al. Furnace Temperature Control for MSWI Process Based on Neural Network Predictive Controller. In: 2024 36th Chinese Control and Decision Conference (CCDC). IEEE, 2024: 1731−1736. [72] Zhou P, Guo D, Chai T. Data-driven predictive control of molten iron quality in blast furnace ironmaking using multi-output LS-SVR based inverse system identification. Neurocomputing, 2018, 308: 101−110 doi: 10.1016/j.neucom.2018.04.060 [73] Tian H, Tang J, Xia H, et al. Bayesian optimization-based interval type-2 fuzzy neural network for furnace temperature control. IEEE Transactions on Industrial Informatics, 2024. [74] Ding H, Qiao J, Huang W, et al. Cooperative Event-Triggered Fuzzy-Neural Multivariable Control with Multi-Task Learning for Municipal Solid Waste Incineration Process. IEEE Transactions on Industrial Informatics, 2023. [75] Zhou G, Tan D. Review of nuclear power plant control research: Neural network-based methods. Annals of Nuclear Energy, 2023, 181: 109513 doi: 10.1016/j.anucene.2022.109513 [76] Ramasamy V, Kannan R, Muralidharan G, et al. A comprehensive review on Advanced Process Control of cement kiln process with the focus on MPC tuning strategies. Journal of Process Control, 2023, 121: 85−102 doi: 10.1016/j.jprocont.2022.12.002 [77] Liu Y J, Zhao W, Liu L, Li D, Tong S, Chen C P. Adaptive neural network control for a class of nonlinear systems with function constraints on states. IEEE Transactions on Neural Networks and Learning Systems, 2021, 34(6): 2732−2741 [78] Cheng L, Wang Z, Jiang F, Li J. Adaptive neural network control of nonlinear systems with unknown dynamics. Advances in Space Research, 2021, 67(3): 1114−1123 doi: 10.1016/j.asr.2020.10.052 [79] Perrusquía A, Yu W. Robot position/force control in unknown environment using hybrid reinforcement learning. Cybernetics and Systems, 2020, 51(4): 542−560 doi: 10.1080/01969722.2020.1758466 [80] Cruz D L, Yu W. Path planning of multi-agent systems in unknown environment with neural kernel smoothing and reinforcement learning. Neurocomputing, 2017, 233: 34−42 doi: 10.1016/j.neucom.2016.08.108 [81] Perrusquía A, Yu W. Neural H? control using continuous-time reinforcement learning. IEEE Transactions on Cybernetics, 2020, 52(6): 4485−4494 [82] Perrusquía A, Yu W. Discrete-time H? neural control using reinforcement learning. IEEE Transactions on Neural Networks and Learning Systems, 2020, 32(11): 4879−4889 [83] 乔俊飞, 韩红桂. 神经网络结构动态优化设计的分析与展望. 控制理论与应用, 2010, 27(03): 350−357Qiao J F, Han H G. Dynamic optimization structure design for neural networks: review and perspective. Control Theory and Applications, 2010, 27(03): 350−357 [84] Baranilingesan I, Deepa S N. An intelligent neural network controller for non-linear CSTR process control. Iranian Journal of Chemistry and Chemical Engineering, 2023, 42(3): 103−116 [85] Emami S A, Castaldi P, Banazadeh A. Neural network-based flight control systems: Present and future. Annual Reviews in Control, 2022, 53: 97−137 doi: 10.1016/j.arcontrol.2022.04.006 [86] Han H, Zhou W, Qiao J, Feng G. A direct self-constructing neural controller design for a class of nonlinear systems. IEEE Transactions on Neural Networks and Learning Systems, 2015, 26(6): 1312−1322 doi: 10.1109/TNNLS.2015.2401395 [87] Han H, Liu H, Li J, Qiao J. Cooperative fuzzy-neural control for wastewater treatment process. IEEE Transactions on Industrial Informatics, 2020, 17(9): 5971−5981 [88] Qiao J F, Li D P, Han H G. Neural Network-Based Adaptive Fault-Tolerant Control of Dissolved Oxygen and Nitrate Concentrations in WWTPs. IEEE Transactions on Industrial Informatics, 2024. [89] Li X, Wang K, Jia C. Data-driven control of ground-granulated blast-furnace slag production based on IOEM-ELM. IEEE Access, 2019, 7: 60650−60660 doi: 10.1109/ACCESS.2019.2915925 [90] Govindan V, Pappa N. Online learning based neural network adaptive controller for efficient power tracking of PWR type reactor with unknown internal dynamics. Annals of Nuclear Energy, 2022, 168: 108866 doi: 10.1016/j.anucene.2021.108866 [91] 游敏. BP神经网络在垃圾焚烧电厂酸性气体排放控制中的应用. 自动化应用, 2024, 65(01): 35−37You M. Application of BP neural network in acid gas emission control in waste incineration power plants. Automation Applications, 2024, 65(01): 35−37 [92] 高阁, 罗大庸. 基于遗传算法的医疗垃圾焚烧控制系统. 计算机测量与控制, 15(4), 470−473.Gao G, Luo D Y. Medical waste incineration control system based on genetic algorithm. Computer Measurement and Control, 2007, 15(4): 470−473. [93] 陶怀志, 孙巍, 赵劲松, 陈晓春, 杨一新. 基于神经网络的垃圾焚烧炉过程控制. 计算机与应用化学, 2008, 25(7): 859−862 doi: 10.3969/j.issn.1001-4160.2008.07.021Tao H Z, Sun W, Zhao J S, Chen X C, Yang Y X. Process control of waste incineration furnace based on neural network. Computer and Applied Chemistry, 2008, 25(7): 859−862 doi: 10.3969/j.issn.1001-4160.2008.07.021 [94] Takaghaj S M, Xu Y, Shi Y, et al. Neural-adaptive control of waste-to-energy steam generators. IEEE Transactions on Control Systems Technology, 2013, 22(5): 1920−1926 [95] Lee S C, Lee E T. Fuzzy neural networks. Mathematical Biosciences, 1975, 23(1−12): 151−177 doi: 10.1016/0025-5564(75)90125-X [96] Dote Y. Fuzzy and neural network controller. In: Proceedings of IECON'90: 16th Annual Conference of IEEE Industrial Electronics Society. IEEE, 1990: 1314−1343. [97] Berenji H R. A reinforcement learning-based architecture for fuzzy logic control. International Journal of Approximate Reasoning, 1992, 6(2): 267−292 doi: 10.1016/0888-613X(92)90020-Z [98] 沈凯, 陆继东, 昌鹏, 李正华, 刘刚. 垃圾焚烧炉炉温控制模糊神经网络模型研究. 燃烧科学与技术, 2004, 10(6): 516−520 doi: 10.3321/j.issn:1006-8740.2004.06.008Shen K, Lu J D, Chang P, Li Z H, Liu G. Research on combustion temperature fuzzy neural network model of incinerators. Journal of Combustion Science and Technology, 2004, 10(6): 516−520 doi: 10.3321/j.issn:1006-8740.2004.06.008 [99] 杨涛, 刘勇, 喻晓红. 基于模糊BP神经网络的垃圾焚烧炉控制系统. 成都大学学报: 自然科学版, 2011, 30(4): 356−360Yang T, Liu Y, Yu X H. Waste incineration furnace control system based on fuzzy BP neural network. Journal of Chengdu University: Natural Science Edition, 2011, 30(4): 356−360 [100] Tian H, Tang J, Xia H, et al. Furnace Temperature Control based on Adaptive TS-FNN for Municipal Solid Waste Incineration Process. In: Proceedings of 2023 35th Chinese Control and Decision Conference (CCDC). IEEE, 2023: 360−365. [101] He H J, Meng X, Tang J, et al. Event-triggered-based self-organizing fuzzy neural network control for the municipal solid waste incineration process. Science China Technological Sciences, 2023, 66(4): 1096−1109 doi: 10.1007/s11431-022-2078-3 [102] Ding H X, Qiao J F, Huang W M, et al. Event-triggered online learning fuzzy-neural robust control for furnace temperature in municipal solid waste incineration process. IEEE Transactions on Automation Science and Engineering, 2023. [103] 汤健, 田昊, 夏恒, 等. 基于区间Ⅱ型FNN的MSWI过程炉膛温度控制. 北京工业大学学报, 20231−11 doi: 10.11936/bjutxb2021080018Tang J, Tian H, Xia H, Qiao J F. Interval Type-Ⅱ FNN-based furnace temperature control for municipal solid waste incineration (MSWI) process. Journal of Beijing University of Technology, 20231−11 doi: 10.11936/bjutxb2021080018 [104] 丁海旭, 汤健, 乔俊飞. 城市固废焚烧过程数据驱动建模与自组织控制. 自动化学报, 2023, 49(3): 1−17Ding H X, Tang J, Qiao J F. Data-driven modeling and self-organizing control of municipal solid waste incineration process. Acta Automatica Sinica, 2023, 49(3): 1−17 [105] Ding H X, Qiao J F, Huang W M, et al. Event-triggered fuzzy neural multivariable control for a municipal solid waste incineration process. Science China Technological Sciences, 2023, 66(11): 3115−3128 doi: 10.1007/s11431-022-2294-3 [106] Takaghaj S M, Xu Y, Shi Y, et al. Neural-adaptive control of waste-to-energy boilers. In: Proceedings of 2012 IEEE 51st Conference on Decision and Control (CDC). IEEE, 2012. [107] Kim J, Calhoun V D, Shim E, Lee J H. Deep neural network with weight sparsity control and pre-training extracts hierarchical features and enhances classification performance: Evidence from whole-brain resting-state functional connectivity patterns of schizophrenia. Neuroimage, 2016, 124: 127−146 doi: 10.1016/j.neuroimage.2015.05.018 [108] Wang C H, Cheng C S, Lee T T. Dynamical optimal training for interval type-2 fuzzy neural network (T2FNN). IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics), 2004, 34(3): 1462−1477 doi: 10.1109/TSMCB.2004.825927 [109] Gaxiola F, Melin P, Valdez F, Castro J R, Castillo O. Optimization of type-2 fuzzy weights in backpropagation learning for neural networks using GAs and PSO. Applied Soft Computing, 2016, 38: 860−871 doi: 10.1016/j.asoc.2015.10.027 [110] Li Q, Pan Y, Zhang Z, et al. Reliable dissipative interval type-2 fuzzy control for nonlinear systems with stochastic incomplete communication route and actuator failure. International Journal of Fuzzy Systems, 2020, 22: 368−379 doi: 10.1007/s40815-020-00807-y [111] Li Y, Zhang Y, Wang Z, et al. Parameter optimization model of heuristic algorithms for controller placement problem in large-scale SDN. IEEE Access, 2020, 8: 151668−151680 doi: 10.1109/ACCESS.2020.3017673 [112] Zhang Y. Neural network algorithm with reinforcement learning for parameters extraction of photovoltaic models. IEEE Transactions on Neural Networks and Learning Systems, 2021, 34(6): 2806−2816 [113] Liu J, Wang Y, Zhang T, et al. Heuristic dynamic programming based online energy management strategy for plug-in hybrid electric vehicles. IEEE Transactions on Vehicular Technology, 2019, 68(5): 4479−4493 doi: 10.1109/TVT.2019.2903119 [114] Han H G, Fu S J, Sun H Y, et al. Modeling and control of wastewater treatment process with time delay based on event-triggered recursive least squares. Engineering Applications of Artificial Intelligence, 2023, 122: 106052 doi: 10.1016/j.engappai.2023.106052 [115] Han H G, Fu S J, Sun H Y, et al. Hierarchical nonlinear model predictive control with multi-time-scale for wastewater treatment process. Journal of Process Control, 2021, 108: 125−135 doi: 10.1016/j.jprocont.2021.11.002 [116] Saagi R, Ramesh A, Jeppsson U, et al. A model library for simulation and benchmarking of integrated urban wastewater systems. Environmental Modelling and Software, 2017, 93: 282−295 doi: 10.1016/j.envsoft.2017.03.026 [117] Jeppsson U, Alex J, Pons M N, et al. Towards a benchmark simulation model for plant-wide control strategy performance evaluation of WWTPs. Water Science and Technology, 2006, 53(1): 287−295 doi: 10.2166/wst.2006.031 [118] Du S L, Qiao J F, Huang W, et al. Dual-mode event-triggered predictive control for nonlinear systems with bounded disturbances. International Journal of Robust and Nonlinear Control, 2024, 34(3): 1878−1897 doi: 10.1002/rnc.7059 [119] Du S L, et al. Event-triggered model predictive control of wastewater treatment plants. Journal of Water Process Engineering, 2022, 47: 102765 doi: 10.1016/j.jwpe.2022.102765 [120] Chen N, Zhou P, Qiao J, et al. Event-triggered optimal control for temperature field of roller kiln based on adaptive dynamic programming. IEEE Transactions on Cybernetics, 2021, 53(5): 2805−2817 [121] Li B, Chen N, Luo B, Chen J, Yang C, Gui W H. ADP-based event-triggered constrained optimal control on spatiotemporal process: application to temperature field in roller kiln. IEEE Transactions on Neural Networks and Learning Systems, 2023, 35(3): 3229−3241 [122] He W, et al. Adaptive consensus control of linear multiagent systems with dynamic event-triggered strategies. IEEE Transactions on Cybernetics, 2019, 50(7): 2996−3008 [123] Sun J Y, et al. Adaptive Distributed Control of Nonlinear Multiagent Systems with Event-Triggered for Communication Faults and Dead-Zone Inputs. IEEE Transactions on Cybernetics, 2024. [124] Zhou H, Zhang Y, Duan W, Zhao H. Nonlinear systems modeling based on self-organizing fuzzy neural network with hierarchical pruning scheme. Applied Soft Computing, 2020, 95: 106516 doi: 10.1016/j.asoc.2020.106516 [125] Wang G, Gui W, Li Y, et al. Data-driven robust adaptive control with deep learning for wastewater treatment process. IEEE Transactions on Industrial Informatics, 2023, 20(1): 149−157 [126] Ai M, Xie Y, Xie S, et al. Data-driven-based adaptive fuzzy neural network control for the antimony flotation plant. Journal of the Franklin Institute, 2019, 356(12): 5944−5960 doi: 10.1016/j.jfranklin.2019.04.032 -

计量

- 文章访问数: 116

- HTML全文浏览量: 109

- 被引次数: 0

下载:

下载: