Data-driven Modeling and Self-organizing Control of Municipal Solid Waste Incineration Process

-

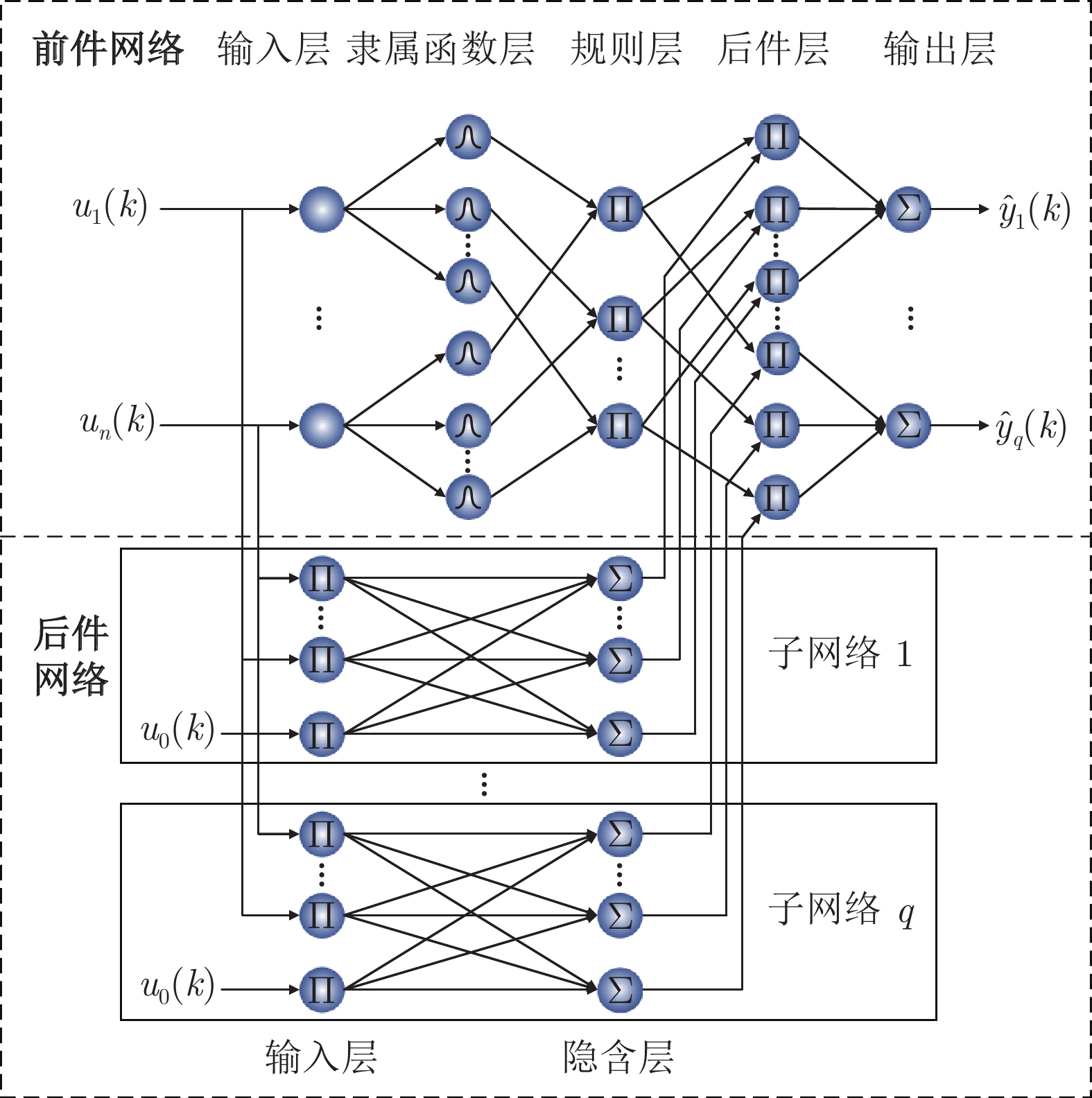

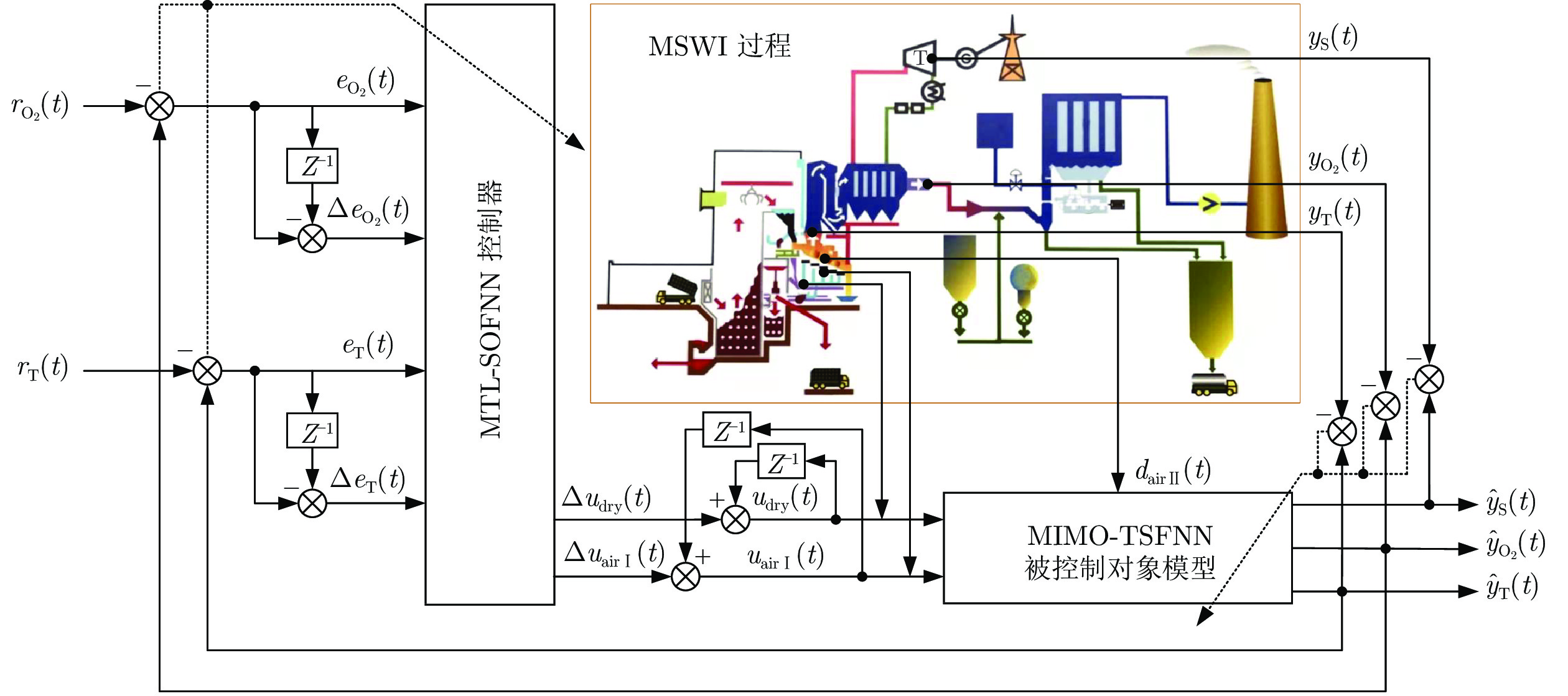

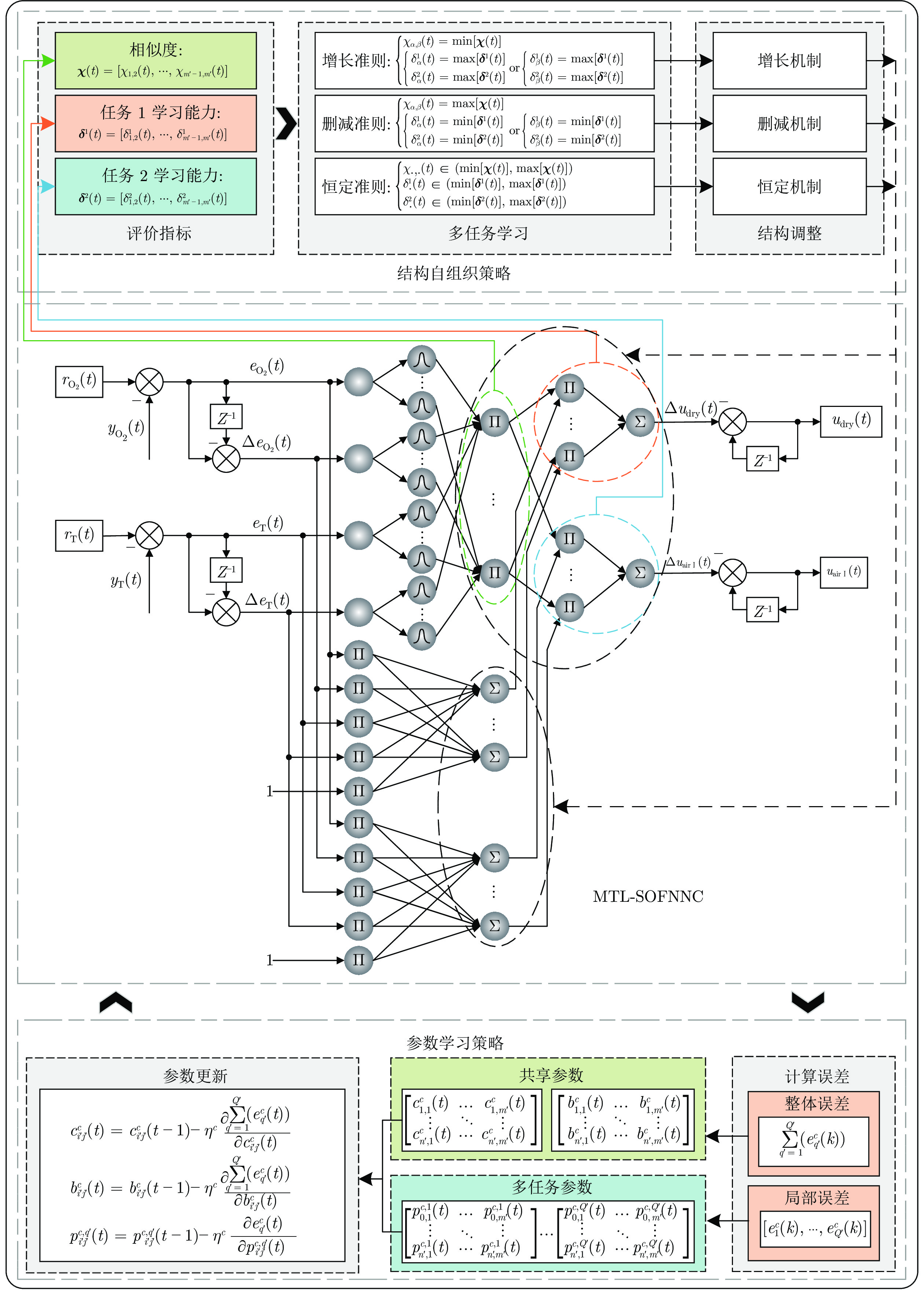

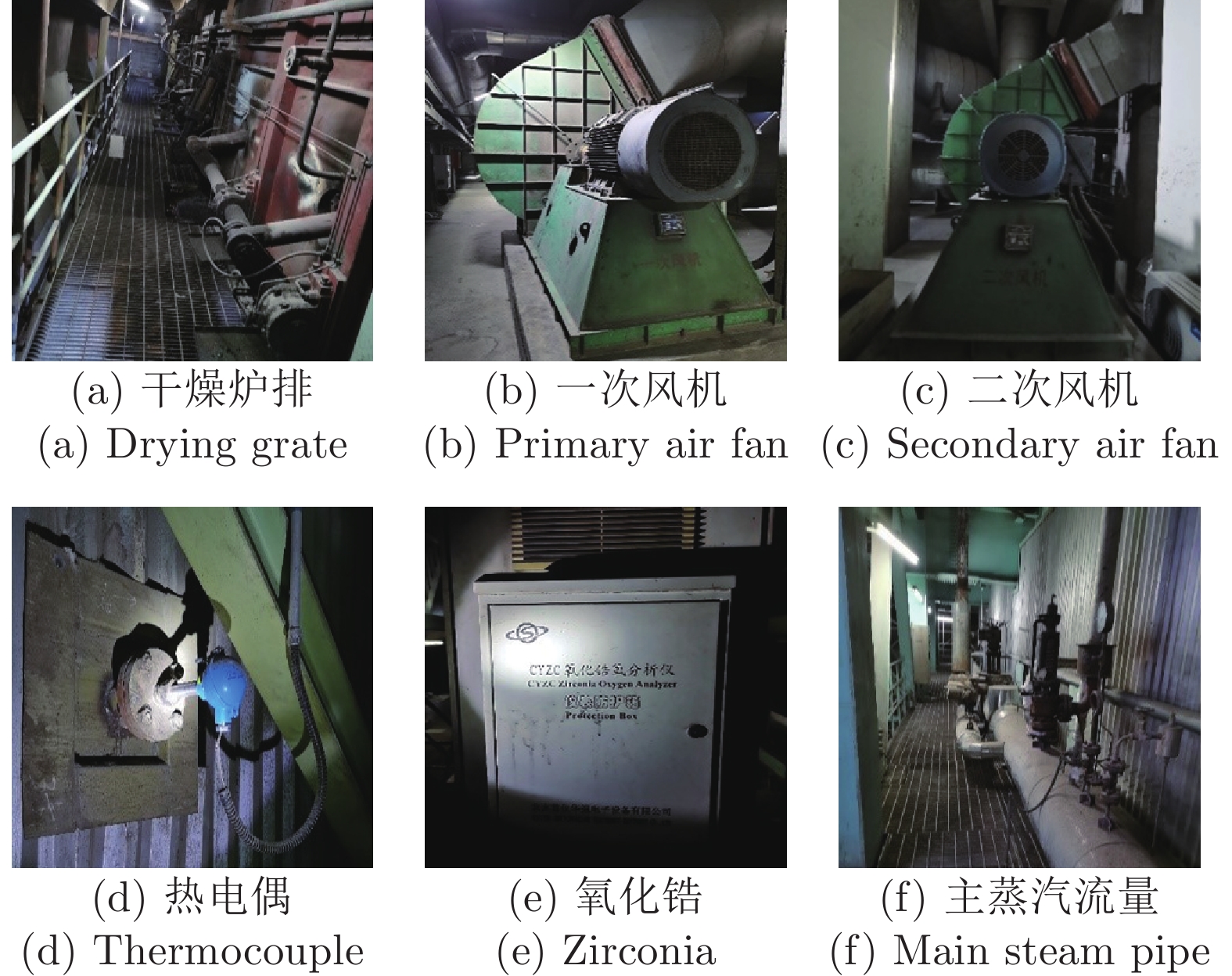

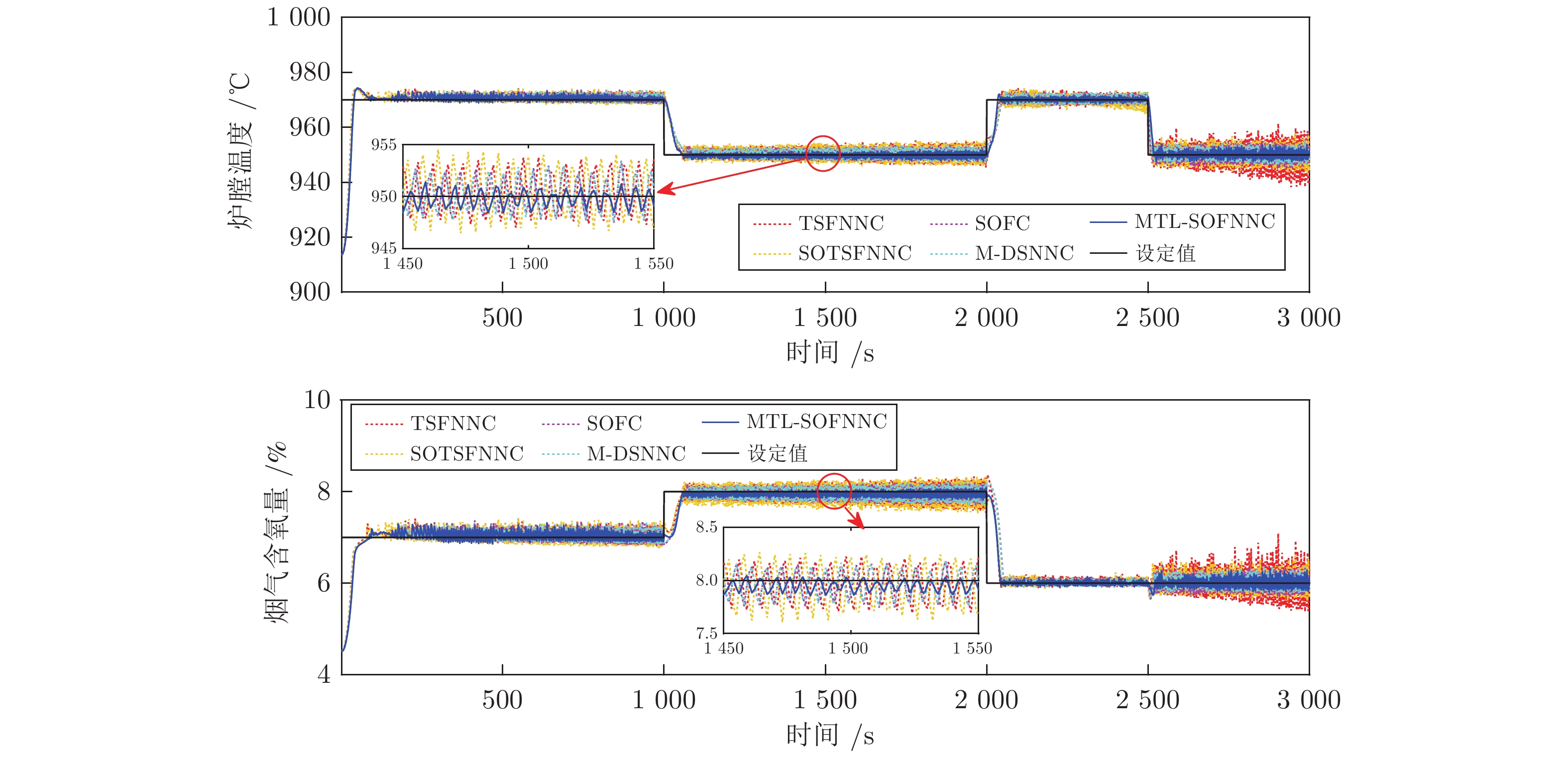

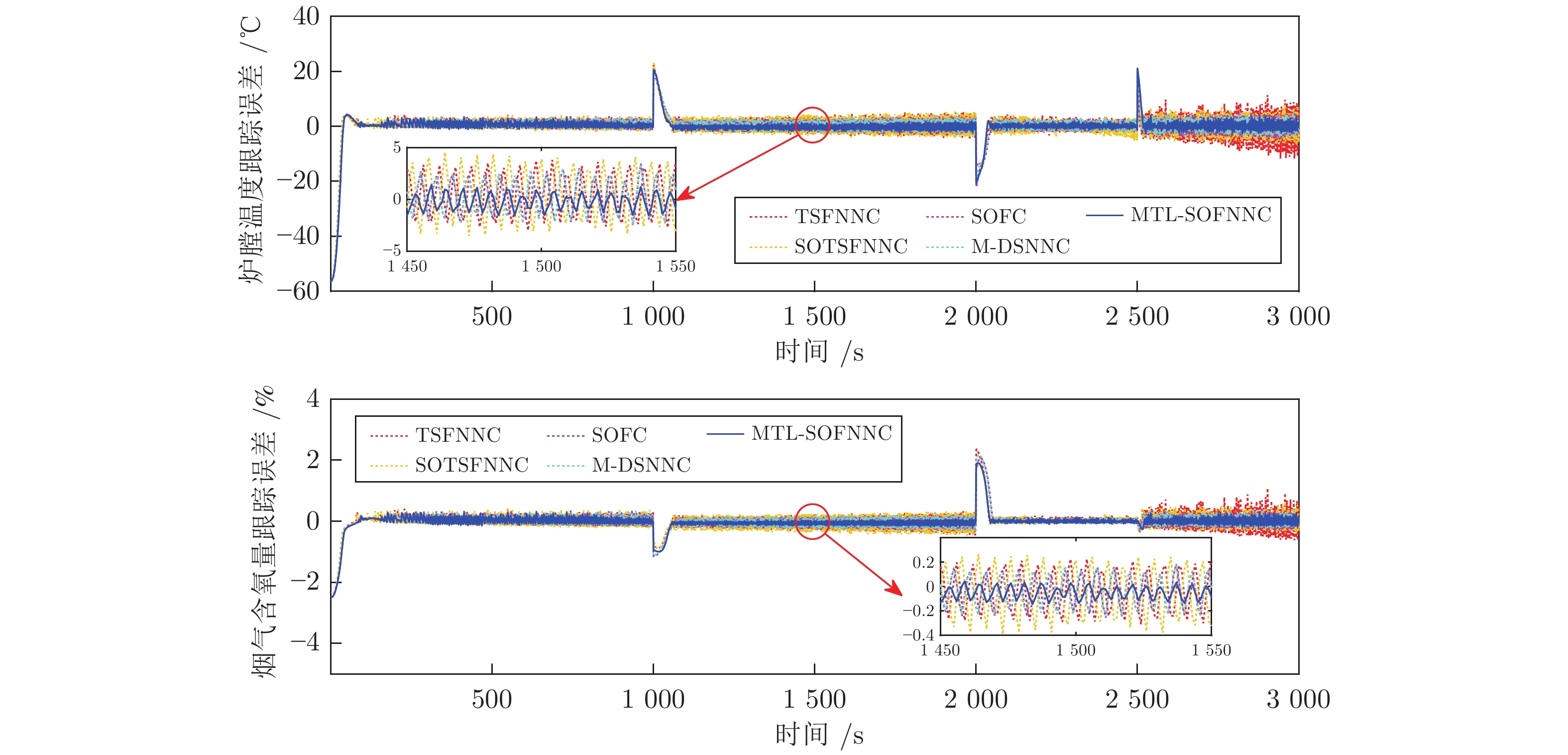

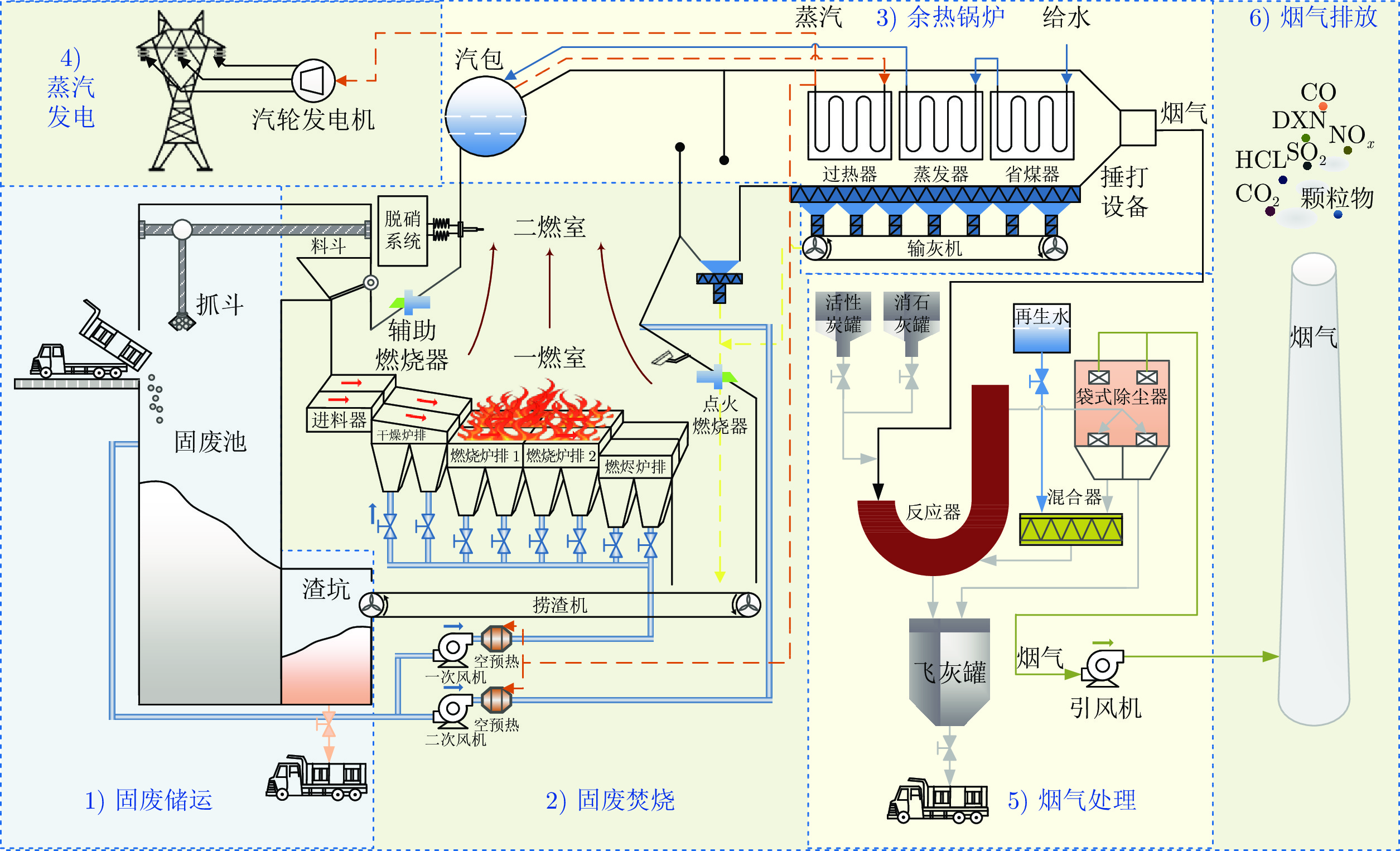

摘要: 城市固废焚烧(Municipal solid waste incineration, MSWI)是处置城市固废(Municipal solid waste, MSW) 的主要手段之一. 中国MSW来源范围广、组分复杂、热值波动大, 其焚烧过程通常依靠人工干预, 这导致MSWI过程智能化水平较低且难以满足日益提升的控制需求. MSWI具有多变量耦合、工况漂移等诸多不确定性特征, 因而难以建立其被控对象模型并设计在线控制器. 针对以上问题, 提出了一种面向MSWI过程的数据驱动建模与自组织控制方法. 首先, 构建了基于多输入多输出Takagi Sugeno 模糊神经网络(Multi-input multi-output Takagi Sugeno fuzzy neural network, MIMO-TSFNN) 的被控对象模型; 然后, 设计了基于多任务学习的自组织模糊神经网络控制器(Multi-task learning self-organizing fuzzy neural network controller, MTL-SOFNNC)用于同步控制炉膛温度与烟气含氧量, 其通过计算神经元的相似度与多任务学习(Multi-task learning, MTL)能力对控制器结构进行自组织调整; 接着, 通过Lyapunov定理对MTL-SOFNNC稳定性进行了证明; 最后, 通过北京市某MSWI厂的过程数据验证了模型与控制器的有效性.Abstract: Municipal solid waste incineration (MSWI) is one of the main means to dispose of municipal solid waste (MSW). MSW in China has a wide range of sources, complex components, and large fluctuations in calorific value. Its incineration process usually relies on manual intervention. This will lead to a low degree of intelligence in the MSWI process and it is difficult to meet the increasing control requirements. MSWI has many uncertain characteristics such as multivariable coupling and working condition drift, so it is difficult to build the model of controlled object and design the on-line controller. To solve the above problems, this paper proposes a data-driven modeling and self-organizing control method for MSWI process. Firstly, the model of controlled object based on multi-input multi-output Takagi Sugeno fuzzy neural network (MIMO-TSFNN) is constructed. Secondly, a multi-task learning self-organizing fuzzy neural network controller (MTL-SOFNNC) is designed to synchronously control the furnace temperature and flue gas oxygen content, which can self-organize the structural parameters of the controller by calculating the similarity of neurons and the ability of multi-task learning (MTL). Meanwhile, the stability of MTL-SOFNNC is proved by Lyapunov theorem. Finally, the effectiveness of the model and controller is verified by the process data of an MSWI plant in Beijing.

-

表 1 实验对象的运行范围

Table 1 Operating range of experimental subjects

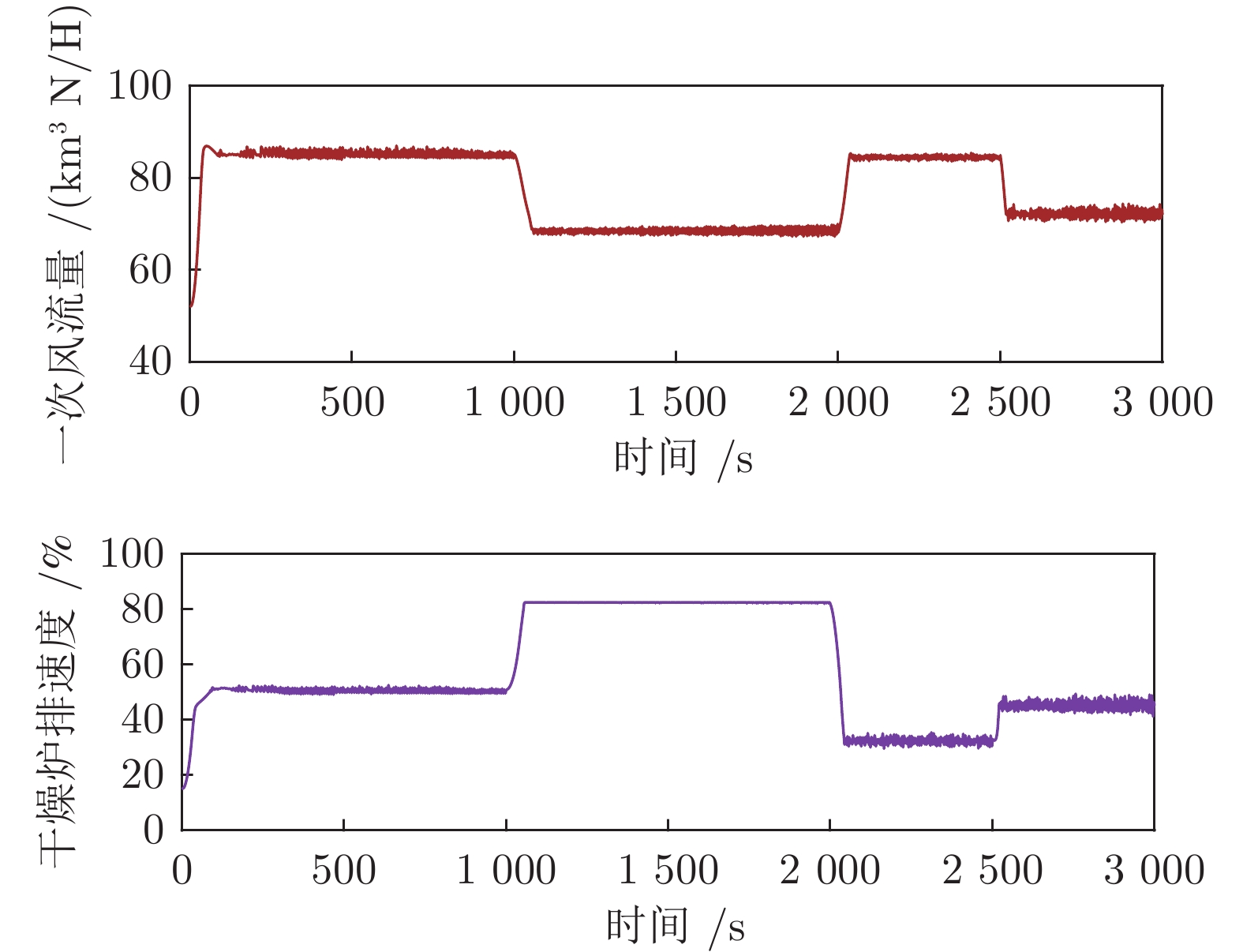

变量名 运行范围 单位 一次风总流量 40 ~ 100 km3 N/h 干燥炉排速度百分比 0 ~ 100 % 二次风流量 0 ~ 30 km3 N/h 炉膛温度 850 ~ 1050 ℃ 烟气含氧量 2 ~ 14 % 主蒸汽流量 65 ~ 85 t/h 表 2 被控对象建模效果评价

Table 2 Evaluation of modeling effect of controlled object model

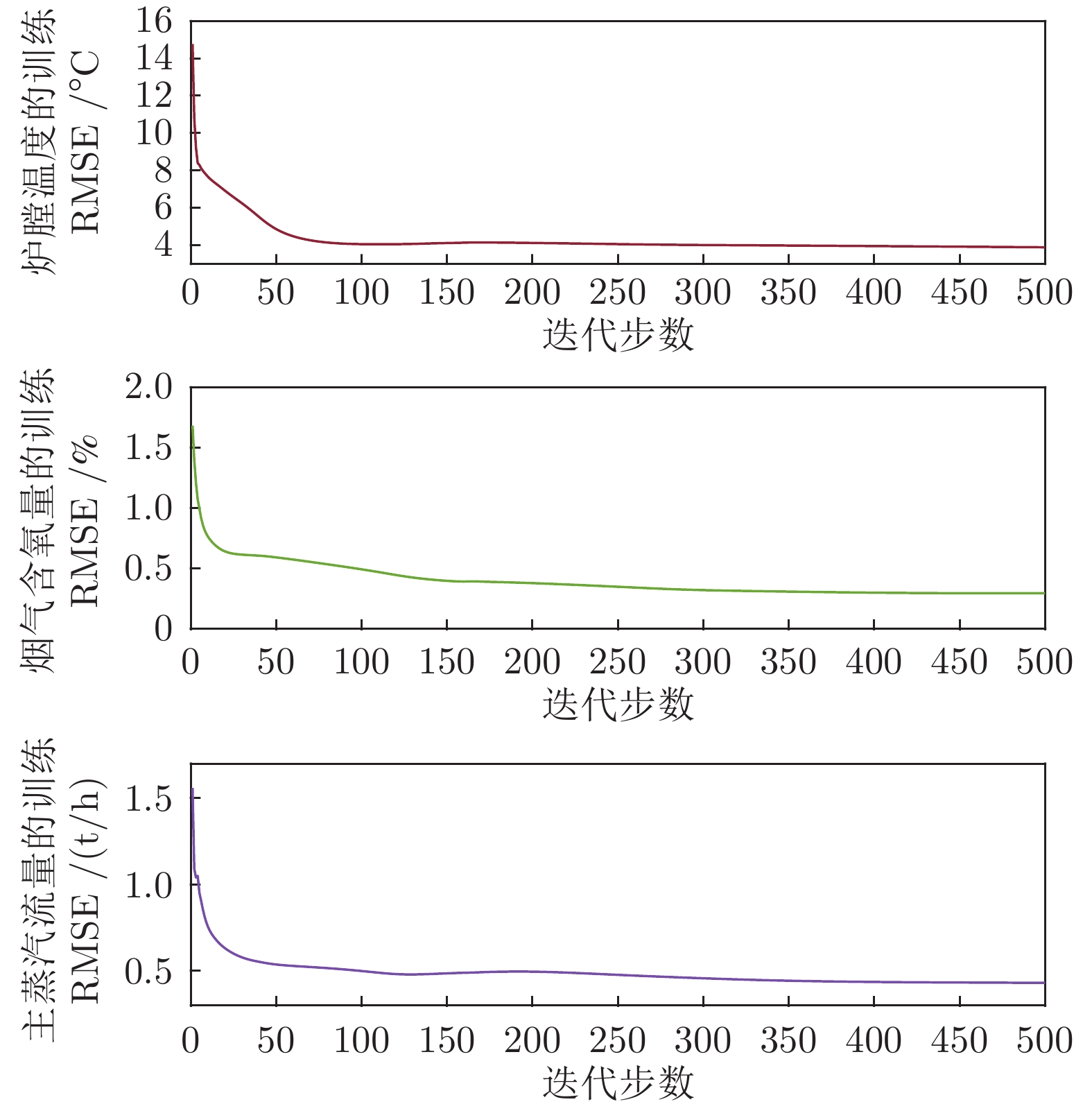

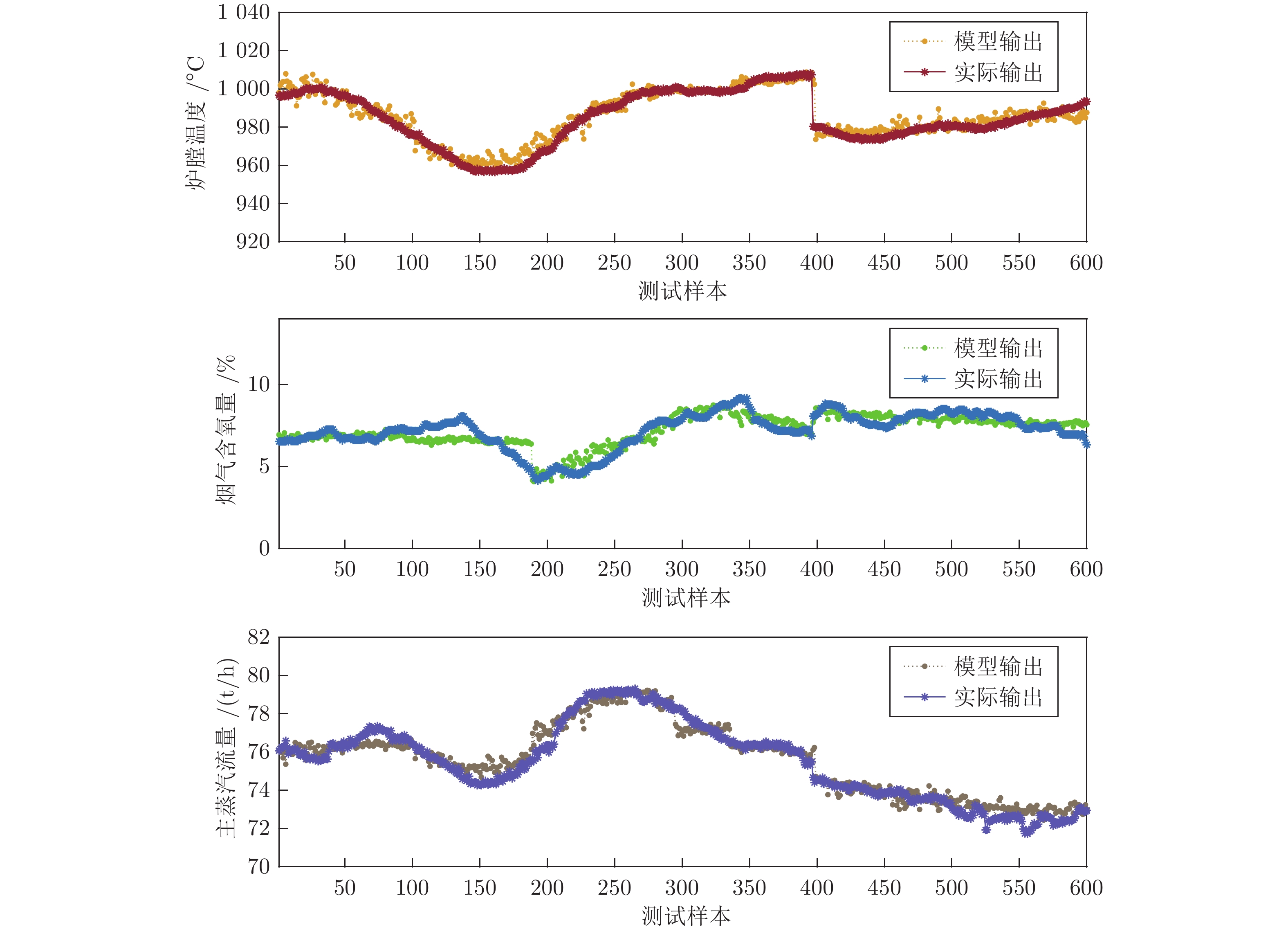

被控模型 评价指标 炉膛温度

模型烟气含氧

量模型主蒸汽

流量模型MIMO-TSFNN 训练 RMSE 3.88 ℃ 0.30% 0.43 t/h APE 0.27% 3.16% 0.45% 测试 RMSE 4.18 ℃ 0.58% 0.49 t/h APE 0.31% 6.97% 0.59% 表 3 MSWI过程多变量控制器性能比较

Table 3 Performance comparison of multi-variable controllers for MSWI process

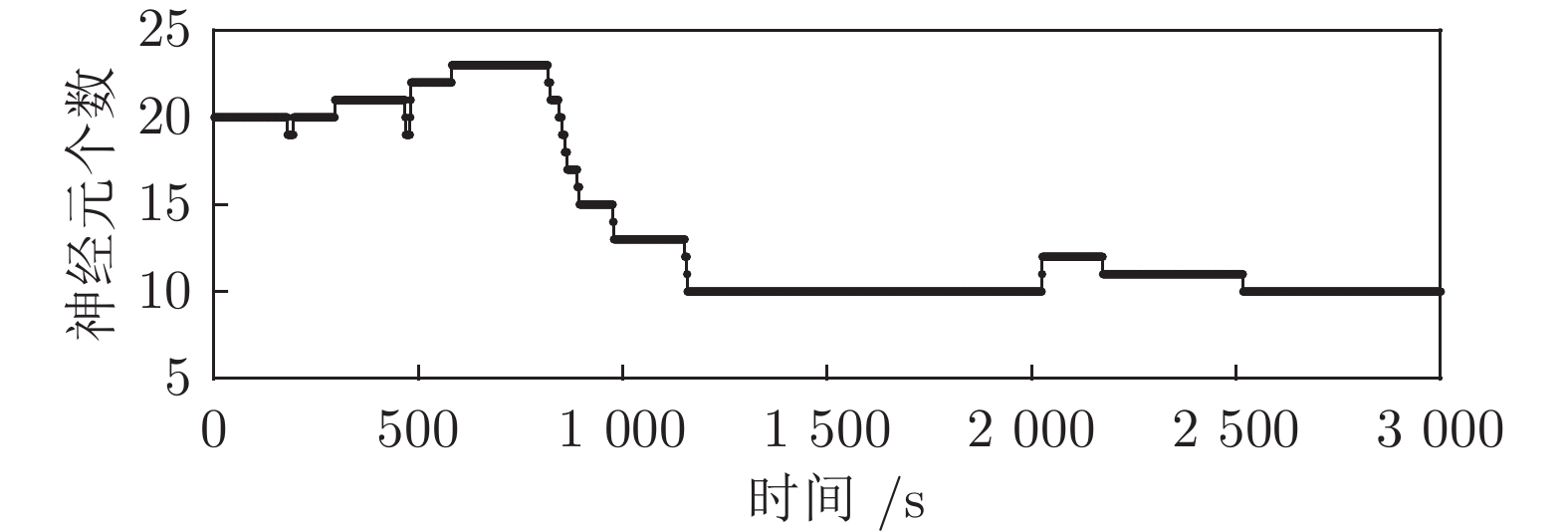

控制器 神经元个数 炉膛温度 烟气含氧量 IAE ISE $ \bar{\sigma}{\text{%}} $ $\bar{t}_r \;({\rm{s} })$ IAE ISE $ \bar{\sigma} {\text{%}}$ $\bar{t}_r\; ({\rm{s} })$ MTL-SOFNNC 10 1.883 28.828 0.39% 23.93 0.151 0.124 3.12% 21.47 M-DSNNC 21 2.379 29.374 0.58% 25.68 0.188 0.150 3.14% 29.47 SOFC 20 2.464 30.229 0.46% 30.43 0.194 0.152 3.92% 29.37 SOTSFNNC 17 2.872 30.414 0.72% 23.38 0.214 0.136 4.13% 27.72 TSFNNC 20 2.854 30.728 0.75% 24.14 0.217 0.151 5.45% 34.77 -

[1] 《中国城市发展报告》委员会. 中国城市发展报告 2020/2021. 北京: 中国城市出版社, 2021.Editorial Board of China Urban Development Report. China Urban Development Report 2020/2021. Beijing: China City Press, 2021. [2] Kaza S, Yao L, Bhadatata P, Woerden F V. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Washington: World Bank Publications, 2018. [3] Shah A V, Srivastava V K, Mohanty S S, Varjani S. Municipal solid waste as a sustainable resource for energy production: State-of-the-art review. Journal of Environmental Chemical Engineering, 2021, 9(4): Article No. 105717 [4] Lu J W, Zhang S, Hai J, Lei M. Status and perspectives of municipal solid waste incineration in China: A comparison with developed regions. Waste Management, 2017, 69: 170-186 doi: 10.1016/j.wasman.2017.04.014 [5] 乔俊飞, 郭子豪, 汤健. 面向城市固废焚烧过程的二噁英排放浓度检测方法综述. 自动化学报, 2020, 46(6): 1063-1089 doi: 10.16383/j.aas.c190005Qiao Jun-Fei, Guo Zi-Hao, Tang Jian. Dioxin emission concentration measurement approaches for municipal solid wastes incineration process: A survey. Acta Automatica Sinica, 2020, 46(6): 1063-1089 doi: 10.16383/j.aas.c190005 [6] Korai M S, Mahar R B, Uqaili M A. The feasibility of municipal solid waste for energy generation and its existing management practices in Pakistan. Renewable and Sustainable Energy Reviews, 2017, 72: 338-353 doi: 10.1016/j.rser.2017.01.051 [7] Bhatt M, Chakinala A G, Joshi J B, Sharma A, Sharma A. Valorization of solid waste using advanced thermo-chemical process: A review. Journal of Environmental Chemical Engineering, 2021, 9(4): Article No. 105434 [8] Kalyani K A, Pandey K K. Waste to energy status in India: A short review. Renewable and Sustainable Energy Reviews, 2014, 31: 113-120 doi: 10.1016/j.rser.2013.11.020 [9] Cheng H, Hu Y. Municipal solid waste (MSW) as a renewable source of energy: Current and future practices in China. Bioresource Technology, 2010, 101(11): 3816-3824 doi: 10.1016/j.biortech.2010.01.040 [10] Chen D, Christensen T H. Life-cycle assessment (EASEWASTE) of two municipal solid waste incineration technologies in China. Waste Management & Research, 2010, 28(6): 508-519 [11] 国家发展改革委. “十四五”城镇生活垃圾分类和处理设施发展规划 [Online], 获取自: https://www.ndrc.gov.cn/xwdt/tzgg/202105/t20210513_1279764.html, May 13, 2021National Development and Reform Commission. The 14th five-year plan for the development of urban domestic waste classification and treatment facilities [Online], available: https://www.ndrc.gov.cn/xwdt/tzgg/202105/t20210513_1279764.html, May 13, 2021 [12] Ding H, Tang J, Qiao J. Control methods of municipal solid wastes incineration process: A survey. In: Proceedings of the 40th Chinese Control Conference. Shanghai, China: IEEE, 2021. 662−667 [13] 郭海涛, 汤健, 丁海旭, 乔俊飞. 基于混合数据增强的 MSWI 过程燃烧状态识别. 自动化学报, DOI: 10.16383/j.aas.c210843Guo Hai-Tao, Tang Jian, Ding Hai-Xu, Qiao Jun-Fei. Combustion states recognition method of mswi process based on mixed data enhancement. Acta Automatica Sinica, DOI: 10.16383/j.aas.c210843 [14] Pan X, Tang J, Ding H, Duan H, Qiao J. Air volume setting model of municipal solid waste incineration process based on color moment features of combustion flame. In: Proceedings of the China Automation Congress. Kunming, China: IEEE, 2021. 7984−7989 [15] Meng X, Tang J, Qiao J. NOx emissions prediction with a brain-inspired modular neural network in municipal solid waste incineration processes. IEEE Transactions on Industrial Informatics, 2022, 18(7): 4622-4631 doi: 10.1109/TII.2021.3116528 [16] 柴天佑. 工业人工智能发展方向. 自动化学报, 2020, 46(10): 2005-2012 doi: 10.16383/j.aas.c200796Chai Tian-You. Development directions of industrial artificial intelligence. Acta Automatica Sinica, 2020, 46(10): 2005-2012 doi: 10.16383/j.aas.c200796 [17] 周平, 赵向志. 面向建模误差PDF形状与趋势拟合优度的动态过程优化建模. 自动化学报, 2021, 47(10): 2402-2411 doi: 10.16383/j.aas.c200001Zhou Ping, Zhao Xiang-Zhi. Optimized modeling of dynamic process oriented towards modeling error PDF shape and goodness of fit. Acta Automatica Sinica, 2021, 47(10): 2402-2411 doi: 10.16383/j.aas.c200001 [18] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931-1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Acta Automatica Sinica, 2018, 44(11): 1931-1943 [19] Ding H, Tang J, Qiao J. MIMO modeling and multi-loop control based on neural network for municipal solid waste incineration. Control Engineering Practice, 2022, 127: Article No. 105280 [20] Saab S S, Hauser M, Ray A. Multivariable nonadaptive controller design. IEEE Transactions on Industrial Electronics, 2020, 68(7): 6181-6191 [21] Zhao D, Li F, Rui M A, Zhao G, Huangfu Y. An unknown input nonlinear observer based fractional order PID control of fuel cell air supply system. IEEE Transactions on Industry Applications, 2020, 56(5): 5523-5532 doi: 10.1109/TIA.2020.2999037 [22] Wang Y, Wang Z, Zou L, Dong H. Multiloop decentralized H∞ fuzzy PID-like control for discrete time-delayed fuzzy systems under dynamical event-triggered schemes. IEEE Transactions on Cybernetics, 2020, 99: 1-13 [23] Çetin G, Özkaraca O, Keçebaş A. Development of PID based control strategy in maximum exergy efficiency of a geothermal power plant. Renewable and Sustainable Energy Reviews, 2021, 137: Article No. 110623 [24] Arruda L V R, Swiech M C S, Neves-Jr F, Delgado M R. Um método evolucionário para sintonia de controladores PI/PID em processos multivariáveis. Sba: Controle & Automação Sociedade Brasileira de Automatica, 2008, 19: 1-17 [25] Han H, Zhang L, Liu H, Qiao J. Multiobjective design of fuzzy neural network controller for wastewater treatment process. Applied Soft Computing, 2018, 67: 467-478 doi: 10.1016/j.asoc.2018.03.020 [26] Qiao J, Hou Y, Zhang L, Han H. Adaptive fuzzy neural network control of wastewater treatment process with multiobjective operation. Neurocomputing, 2018, 275(31): 383-393 [27] Dai W, Chai T, Yang S X. Data-driven optimization control for safety operation of hematite grinding process. IEEE Transactions on Industrial Electronics, 2014, 62(5): 2930-2941 [28] Wan J, Huang M, Ma Y, Guo W, Wang Y, Zhang H, et al. Prediction of effluent quality of a paper mill wastewater treatment using an adaptive network-based fuzzy inference system. Applied Soft Computing, 2011, 11(3): 3238-3246 doi: 10.1016/j.asoc.2010.12.026 [29] Chen C S. Robust self-organizing neural-fuzzy control with uncertainty observer for MIMO nonlinear systems. IEEE Transactions on Fuzzy Systems, 2011, 19(4): 694-706 doi: 10.1109/TFUZZ.2011.2136349 [30] Wu H, Qin S, Nie R, Cao J, Gorbachev S. Effective collaborative representation learning for multilabel text categorization. IEEE Transactions on Neural Networks and Learning Systems, 2021, 99: 1-15 [31] Ku C C, Lee K Y. Diagonal recurrent neural networks for dynamic systems control. IEEE Transactions on Neural Networks, 1995, 6(1): 144-156 doi: 10.1109/72.363441 [32] Zhang W, Qiao J. Multi-variable direct self-organizing fuzzy neural network control for wastewater treatment process. Asian Journal of Control, 2020, 22(2): 716-728 doi: 10.1002/asjc.1919 [33] Qiao J, Zhang W, Han H. Self-organizing fuzzy control for dissolved oxygen concentration using fuzzy neural network 1. Journal of Intelligent & Fuzzy Systems, 2016, 30(6): 3411-3422 [34] 乔俊飞, 付文韬, 韩红桂. 基于SOTSFNN的溶解氧浓度控制方法. 化工学报, 2016, 67(3): 960-966Qiao Jun-Fei, Fu Wen-Tao, Han Hong-Gui. Dissolved oxygen control method based on self-organizing T-S fuzzy neural network. CIESC Journal, 2016, 67(3): 960-966 -

下载:

下载: