Review of Root Cause Diagnosis and Propagation Path Identification Techniques for Faults in Industrial Processes

-

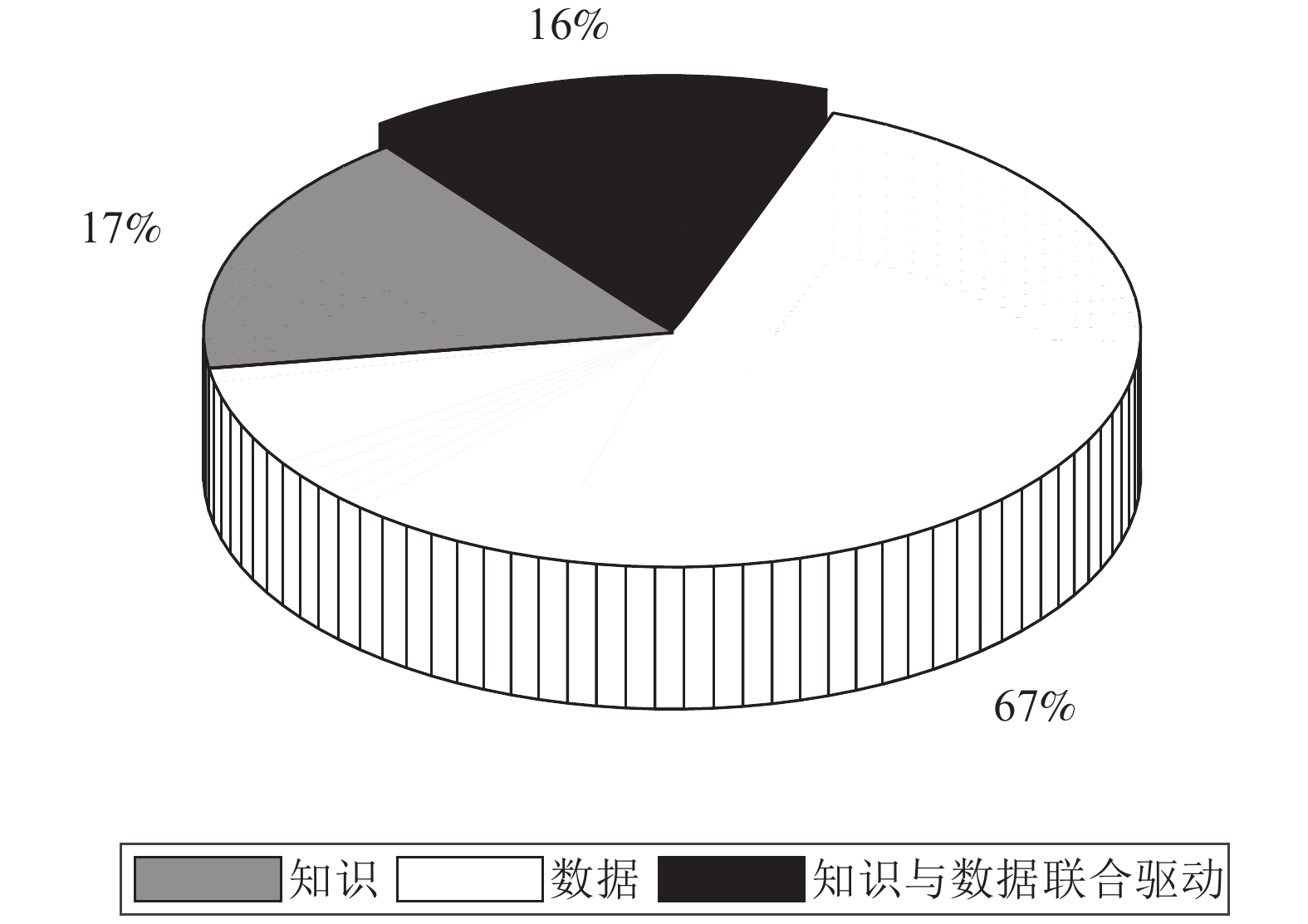

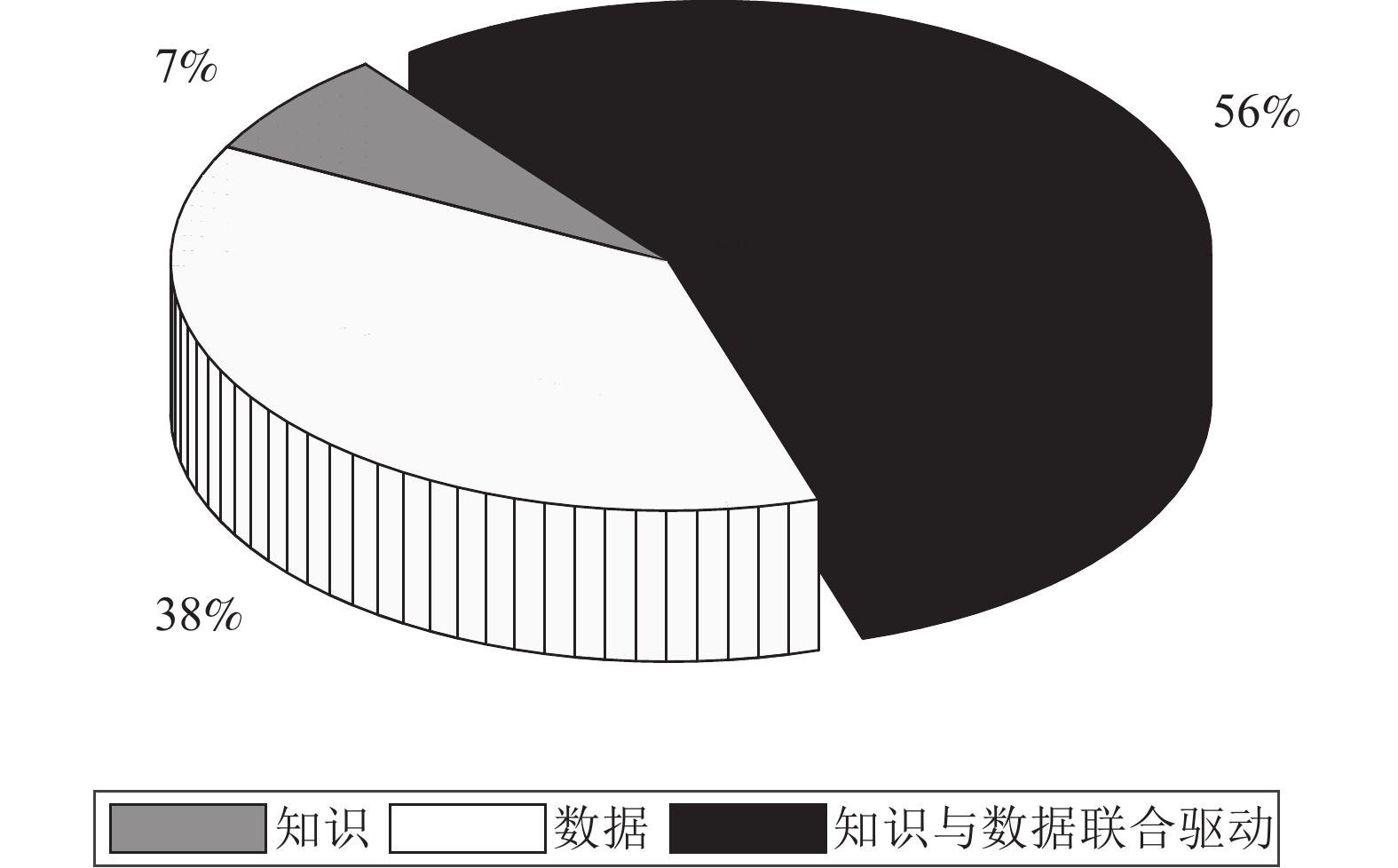

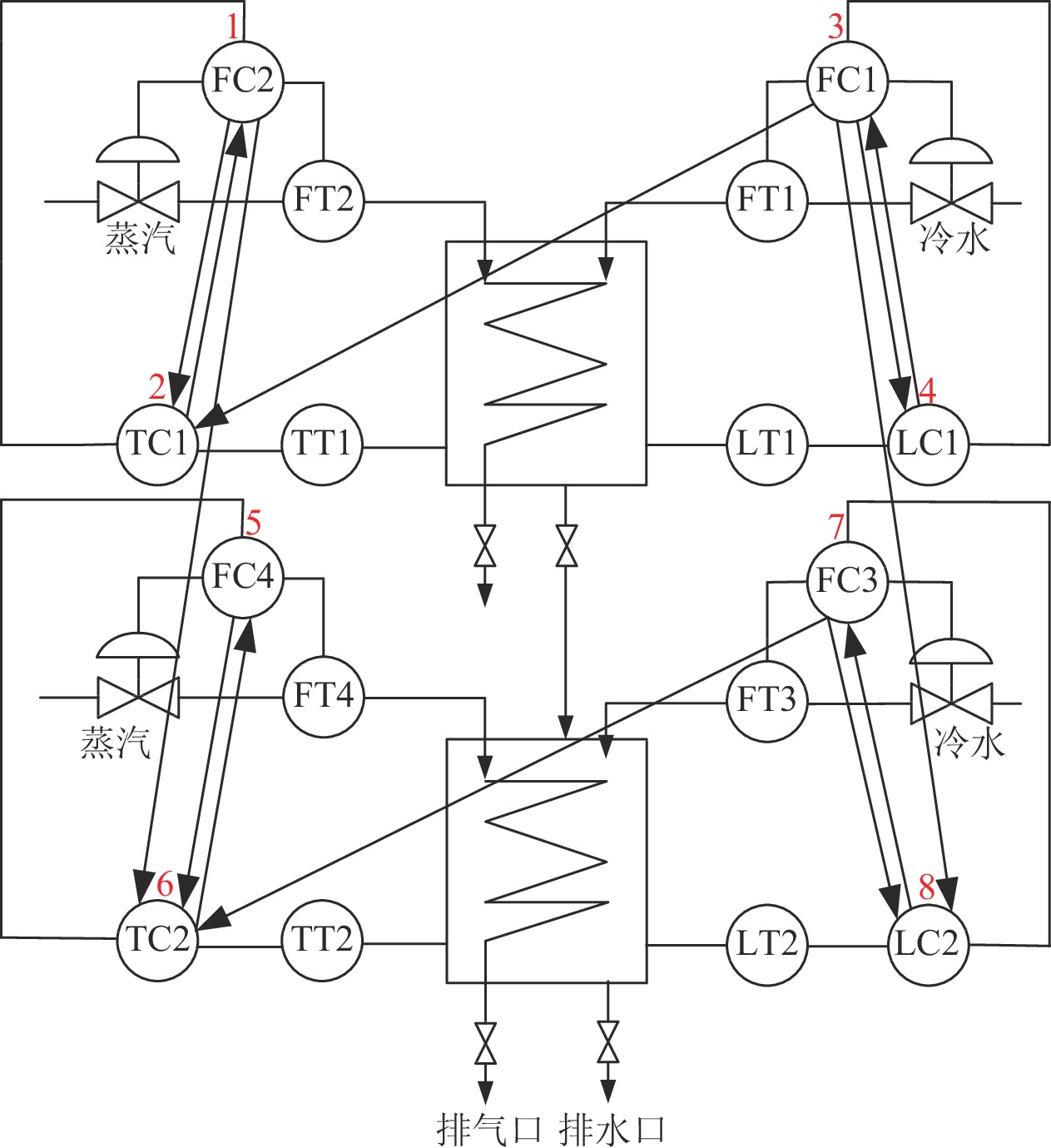

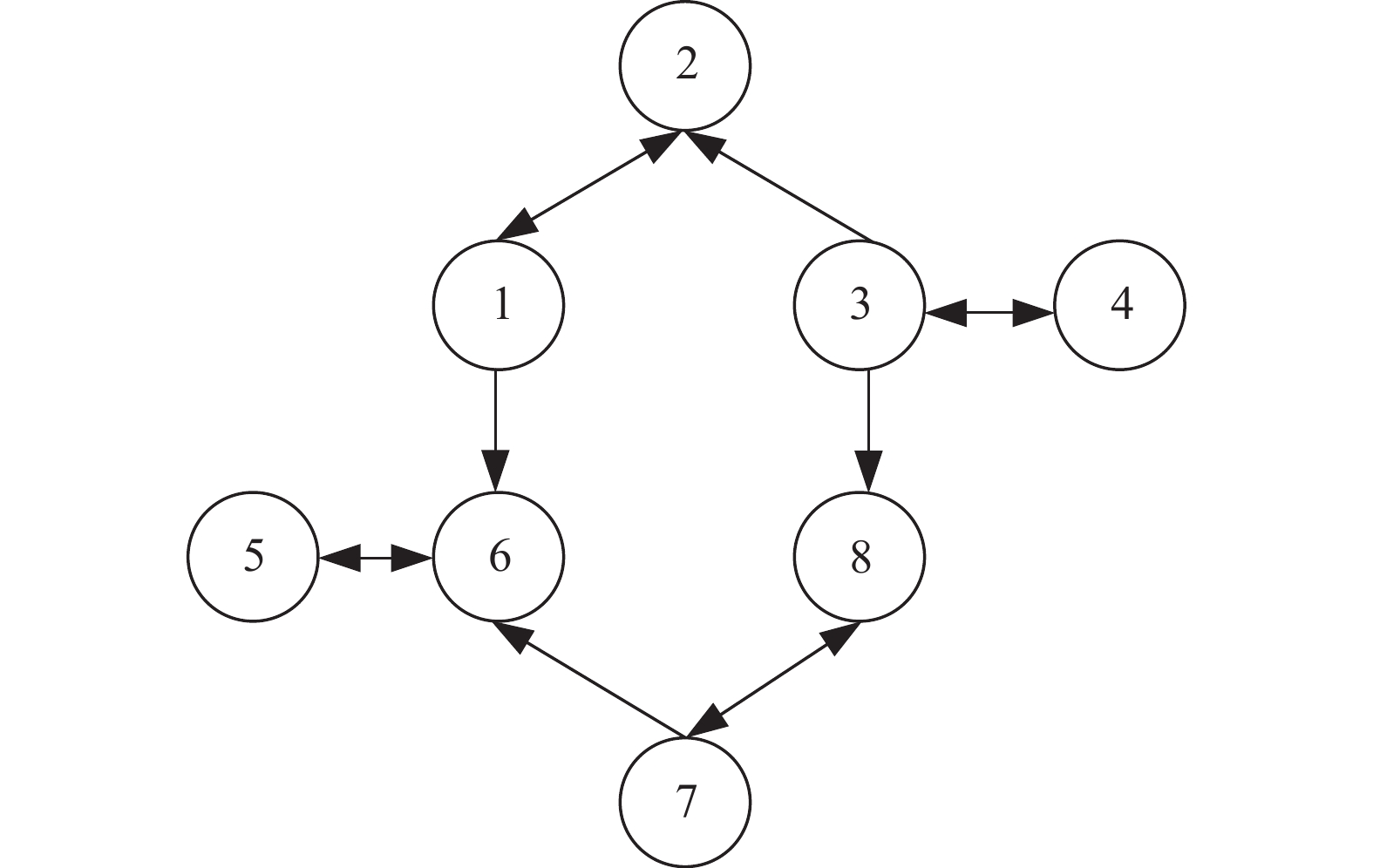

摘要: 故障根源诊断与传播路径识别是故障诊断框架下的关键核心问题, 是保障工业过程安全生产及获得可靠产品质量的有效手段, 是当前过程控制领域的研究热点. 该技术的研究不仅丰富了故障诊断理论, 而且对故障诊断技术在工程中的推广与应用具有重要意义. 阐述了基于知识、数据及知识与数据联合驱动的故障根源诊断与传播路径识别方法的基本思想、适用条件和优劣特点, 分类概述了相关方法的研究现状. 探讨了该领域亟待解决的问题及未来的发展方向, 包括: 1)“三个维度”视角下的工业过程故障根源诊断与传播路径识别; 2)基于制造大数据分析与因果关系挖掘的工业过程质量精准追溯; 3)面向传播、耦合、多重并发特性的工业过程复合故障分布式诊断; 4)基于多源异构动态信息融合的工业过程异常工况时空追溯可视化.Abstract: Root cause diagnosis and propagation path identification are the key issues under fault diagnosis framework, which are effective means to guarantee safety production and obtain reliable product quality for industrial processes, and thus, have recently become active areas of process control field. Research of these two techniques not only enriches the fault diagnosis theory, but also has important significance for promotion and application of fault diagnosis technology in actual projects. In this paper, the basic ideas, application conditions, advantages, as well as disadvantages of knowledge based, data based and joint knowledge and data based methods are illustrated. Moreover, research status of related methods is classified and summarized. Finally, some urgent problems and future directions in this field are discussed, including: 1) Root cause diagnosis and propagation path identification under three-dimensional perspective; 2) Manufacturing big data analysis and causality mining based accurate quality tracing; 3) Distributed diagnosis for propagative, coupled, and concurrent multiple faults; 4) Multi-source heterogeneous dynamic information fusion based timespace traceability visualization for abnormal conditions.1) 收稿日期2020-04-27 录用日期2020-08-27 Manuscript received April 27, 2020; accepted August 27, 2020 国家自然科学基金(62003030, 61873024, 61773053), 中国博士后科学基金资助项目(2019M660464), 广东省基础与应用基础研究基金(2019A1515110991), 中央高校基本科研业务费专项资金资助项目(FRF-TP-19-049A1Z), 北京科技大学顺德研究生院博士后科研经费(2020BH003)资助 Supported by National Natural Science Foundation of China (62003030, 61873024, 61773053), Project Funded by China Postdoctoral Science Foundation (2019M660464), Guangdong Basic and Applied Basic Research Foundation (2019A1515110991), Fundamental Research Funds for the China Central Universities (FRF-TP-19-049A1Z), and Postdoctor Research Foundation of Shunde Graduate School of University of Science and Technology Beijing (2020BH003) 本文责任编委 杨涛 Recommended by Associate Editor YANG Tao 1. 北京科技大学顺德研究生院 佛山528399 2. 北京科技大学自动化学院 北京100083 3. 工业过程知识自动化教育部重点实验室 北京1000832) 1. Shunde Graduate School of University of Science and Technology Beijing, Foshan 528399 2. School of Automation and Electrical Engineering, University of Science and Technology Beijing, Beijing 100083 3. Key Laboratory of Knowledge Automation for Industrial Processes of Ministry of Education, Beijing 100083

-

表 1 基于知识的故障根源诊断与传播路径识别方法对比

Table 1 Comparisons of knowledge based root cause diagnosis and propagation path identification methods

方法 优势 劣势 SDG 模型构建简单,

分析完备性强面向定性信息缺乏的工业系统易产生虚假和冗余解 邻接矩阵 基本原理简单,

结果易于理解模型构建工作量巨大, 缺少节点间间接关联关系信息 FT 模型直观明了,

推理过程清晰高度依赖专家经验, 对不确定性问题诊断准确率较低 MFM 语义符号简单,

诊断规则一致面向复杂系统功能节点抽象与深层次诊断难度较大 Petri 网 数学表述严格,

图形表达直观建模高度依赖机理, 随机不确定条件下诊断准确率低 表 2 基于数据的故障根源诊断与传播路径识别方法对比

Table 2 Comparisons of data based root cause diagnosis and propagation path identification methods

方法 优势 劣势 CCA 基本原理简单,

过程易于实现无法分析非线性因果关系及区分直接与间接因果关系 GC 计算复杂度低,

具有预测功能无法分析非线性因果关系, 容易出现虚假冗余因果关系 TE 可分析线性及非

线性因果关系联合概率分布函数计算量大, 无法区分直接与间接因果关系 KNN 对数据无假设,

计算复杂度低对样本不平衡问题诊断效果较差, $ k $值选择无理论依据 BN 能够融合表达

过程多源信息网络训练过程相对繁琐, 最优网络结构难以获取与保证 -

[1] 柴天佑, 丁进良. 流程工业智能优化制造. 中国工程科学, 2018, 20(4): 51-58Chai Tian-You, Ding Jin-Liang. Smart and optimal manufacturing for process industry. Strategic Study of CAE, 2018, 20(4): 51-58 [2] 桂卫华, 阳春华, 陈晓方, 王雅琳. 有色冶金过程建模与优化的若干问题及挑战. 自动化学报, 2013, 39(3): 197-207 doi: 10.1016/S1874-1029(13)60022-1Gui Wei-Hua, Yang Chun-Hua, Chen Xiao-Fang, Wang Ya-Lin. Modeling and optimization problems and challenges arising in nonferrous metallurgical processes. Acta Automatica Sinica, 2013, 39(3): 197-207 doi: 10.1016/S1874-1029(13)60022-1 [3] 钱锋, 杜文莉, 钟伟民, 唐漾. 石油和化工行业智能优化制造若干问题及挑战. 自动化学报, 2017, 43(6): 893-901Qian Feng, Du Wen-Li, Zhong Wei-Min, Tang Yang. Problems and challenges of smart optimization manufacturing in petrochemical industries. Acta Automatica Sinica, 2017, 43(6): 893-901 [4] 刘强, 卓洁, 郎自强, 秦泗钊. 数据驱动的工业过程运行监控与自优化研究展望. 自动化学报, 2018, 44(11): 1944-1956Liu Qiang, Zhuo Jie, Lang Zi-Qiang, Qin S. Joe. Perspectives on data-driven operation monitoring and self-optimization of industrial processes. Acta Automatica Sinica, 2018, 44(11): 1944-1956 [5] Tidriri K, Chatti N, Verron S, Tiplica T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annual Reviews in Control, 2016, 42: 63-81 doi: 10.1016/j.arcontrol.2016.09.008 [6] Qin S J. Survey on data-driven industrial process monitoring and diagnosis. Annual Reviews in Control, 2012, 36(2): 220-234 doi: 10.1016/j.arcontrol.2012.09.004 [7] Ge Z Q. Review on data-driven modeling and monitoring for plant-wide industrial processes. Chemometrics and Intelligent Laboratory Systems, 2017, 171: 16-25 doi: 10.1016/j.chemolab.2017.09.021 [8] Jiang Y C, Yin S. Recent advances in key-performance-indicator oriented prognosis and diagnosis with a MATLAB toolbox: DB-KIT. IEEE Transactions on Industrial Informatics, 2019, 15(5): 2849-2858 doi: 10.1109/TII.2018.2875067 [9] Duan P, Chen T W, Shah S L, Yang F. Methods for root cause diagnosis of plant-wide oscillations. AIChE Journal, 2014, 60(6): 2019-2034 doi: 10.1002/aic.14391 [10] Wang J D, Yang F, Chen T W, Shah S L. An overview of industrial alarm systems: Main causes for alarm overloading, research status, and open problems. IEEE Transactions on Automation Science and Engineering, 2016, 13(2): 1045-1061 doi: 10.1109/TASE.2015.2464234 [11] 朱群雄, 高慧慧, 徐圆. 工业过程报警管理研究进展. 自动化学报, 2017, 43(6): 955-968Zhu Qun-Xiong, Gao Hui-Hui, Xu Yuan. A survey on alarm management for industrial processes. Acta Automatica Sinica, 2017, 43(6): 955-968 [12] 吴军强, 梁军. 基于图论的故障诊断技术及其发展. 机电工程, 2003, 20(5): 188-190 doi: 10.3969/j.issn.1001-4551.2003.05.070Wu Jun-Qiang, Liang Jun. Technology and development of fault diagnosis based on graph theory. Mechanical & Electrical Engineering Magazine, 2003, 20(5): 188-190 doi: 10.3969/j.issn.1001-4551.2003.05.070 [13] 刘鹏鹏, 左洪福, 苏艳, 孙见忠. 基于图论模型的故障诊断方法研究进展综述. 中国机械工程, 2013, 24(5): 696-703 doi: 10.3969/j.issn.1004-132X.2013.05.027Liu Peng-Peng, Zuo Hong-Fu, Su Yan, Sun Jian-Zhong. Review of research progresses for graph-based models in fault diagnosis method. China Mechanical Engineering, 2013, 24(5): 696-703 doi: 10.3969/j.issn.1004-132X.2013.05.027 [14] Maurya M R, Rengaswamy R, Venkatasubramanian V. Application of signed digraphs-based analysis for fault diagnosis of chemical process flowsheets. Engineering Applications of Artificial Intelligence, 2004, 17(5): 501-518 doi: 10.1016/j.engappai.2004.03.007 [15] 杨帆, 萧德云. SDG建模及其应用的进展. 控制理论与应用, 2005, 22(5): 767-774 doi: 10.3969/j.issn.1000-8152.2005.05.019Yang Fan, Xiao De-Yun. Review of SDG modeling and its application. Control Theory & Applications, 2005, 22(5): 767-774 doi: 10.3969/j.issn.1000-8152.2005.05.019 [16] Jiang H L, Patwardhan R, Shah S L. Root cause diagnosis of plant-wide oscillations using the concept of adjacency matrix. Journal of Process Control, 2009, 19(8): 1347-1354 doi: 10.1016/j.jprocont.2009.04.013 [17] Jiang H L, Patwardhan R, Shah S L. Root cause diagnosis of plant-wide oscillations using the adjacency matrix. In: Proceedings of the 17th World Congress, the International Federation of Automatic Control. Seoul, South Korea: IFAC, 2008. 13893−13900 [18] Kabir S. An overview of fault tree analysis and its application in model based dependability analysis. Expert Systems With Applications, 2017, 77: 114-135 doi: 10.1016/j.eswa.2017.01.058 [19] Dahlstrand F. Consequence analysis theory for alarm analysis. Knowledge-Based Systems, 2002, 15(1–2): 27-36 doi: 10.1016/S0950-7051(01)00118-6 [20] Kabir S, Papadopoulos Y. Applications of Bayesian networks and Petri nets in safety, reliability, and risk assessments: A review. Safety Science, 2019, 115: 154-175 doi: 10.1016/j.ssci.2019.02.009 [21] Yang F, Xiao D Y. Probabilistic SDG model description and fault inference for large-scale complex systems. High Technology Letters, 2006, 12(3): 239-244 [22] Lü N, Xiong Z H, Wang X, Ren C R. Integrated framework of probabilistic signed digraph based fault diagnosis approach to a gas fractionation unit. Industrial & Engineering Chemistry Research, 2011, 50(17): 10062-10073 [23] 张红林, 付剑, 张春元, 王英鸿. 基于同构节点的动态故障树分析方法. 计算机工程与设计, 2011, 32(1): 1-4Zhang Hong-Lin, Fu Jian, Zhang Chun-Yuan, Wang Ying-Hong. Dynamic fault tree analysis method based on isomorphic node. Computer Engineering and Design, 2011, 32(1): 1-4 [24] Marquez D, Neil M, Fenton N. Solving dynamic fault trees using a new hybrid Bayesian network inference algorithm. In: Proceedings of the 16th Mediterranean Conference on Control and Automation. Ajaccio, France: IEEE, 2008. 609−614 [25] 崔铁军, 李莎莎. 空间故障树与空间故障网络理论综述. 安全与环境学报, 2019, 19(2): 399-405Cui Tie-Jun, Li Sha-Sha. Revision of the space fault tree and the space fault network system. Journal of Safety and Environment, 2019, 19(2): 399-405 [26] 高庆, 陈云飞. 加权模糊Petri网在故障诊断中的应用. 科学技术与工程, 2007, 7(24): 6453-6456 doi: 10.3969/j.issn.1671-1815.2007.24.044Gao Qing, Chen Yun-Fei. Application of weighted fuzzy Petri net in fault diagnosis. Science Technology and Engineering, 2007, 7(24): 6453-6456 doi: 10.3969/j.issn.1671-1815.2007.24.044 [27] Sun J, Qin S Y, Song Y H. Fault diagnosis of electric power systems based on fuzzy Petri nets. IEEE Transactions on Power Systems, 2004, 19(4): 2053-2059 doi: 10.1109/TPWRS.2004.836256 [28] 郭亚中, 左洪福, 王华伟. 基于CRPN模型的复杂系统故障诊断. 华南理工大学学报(自然科学版), 2007, 35(1): 24-27, 33Guo Ya-Zhong, Zuo Hong-Fu, Wang Hua-Wei. Fault diagnosis of complex system based on CRPN model. Journal of South China University of Technology (Natural Science Edition), 2007, 35(1): 24-27, 33 [29] Bauer M, Thornhill N F. A practical method for identifying the propagation path of plant-wide disturbances. Journal of Process Control, 2008, 18(7–-8): 707-719 doi: 10.1016/j.jprocont.2007.11.007 [30] Yang B, Li H G, Wen B. A dynamic time delay analysis approach for correlated process variables. Chemical Engineering Research and Design, 2017, 122: 141-150 doi: 10.1016/j.cherd.2017.04.010 [31] Granger C W J. Investigating causal relations by econometric models and cross-spectral methods. Econometrica, 1969, 37(3): 424-438 doi: 10.2307/1912791 [32] Bressler S L, Seth A K. Wiener-Granger causality: A well established methodology. NeuroImage, 2011, 58(2): 323-329 doi: 10.1016/j.neuroimage.2010.02.059 [33] 尹进田, 谢永芳, 陈志文, 彭涛, 杨超. 基于故障传播与因果关系的故障溯源方法及其在牵引传动控制系统中的应用. 自动化学报, 2020, 46(1): 47-57Yin Jin-Tian, Xie Yong-Fang, Chen Zhi-Wen, Peng Tao, Yang Chao. Fault tracing method based on fault propagation and causality with its application to the traction drive control system. Acta Automatica Sinica, 2020, 46(1): 47-57 [34] Li G, Qin S J, Yuan T. Data-driven root cause diagnosis of faults in process industries. Chemometrics and Intelligent Laboratory Systems, 2016, 159: 1-11 doi: 10.1016/j.chemolab.2016.09.006 [35] Ma L, Dong J, Peng K X. A novel key performance indicator oriented hierarchical monitoring and propagation path identification framework for complex industrial processes. ISA Transactions, 2020, 96: 1-13 doi: 10.1016/j.isatra.2019.06.004 [36] Ancona N, Marinazzo D, Stramaglia S. Radial basis function approach to nonlinear Granger causality of time series. Physical Review E, 2004, 70(5): Article No. 056221 [37] Marinazzo D, Pellicoro M, Stramaglia S. Kernel method for nonlinear Granger causality. Physical Review Letters, 2008, 100: Article No. 144103 [38] Chen H S, Yan Z B, Yao Y, Huang T B, Wong Y S. Systematic procedure for Granger-causality-based root cause diagnosis of chemical process faults. Industrial & Engineering Chemistry Research, 2018, 57(29): 9500-9512 [39] He F, Wang C J, Fan S K S. Fault detection and root cause analysis of a batch process via novel nonlinear dissimilarity and comparative Granger causality analysis. Industrial & Engineering Chemistry Research, 2019, 58(47): 21842-21854 [40] Ahmed U, Ha D, Shin S, Shaukat N, Zahid U, Han C H. Estimation of disturbance propagation path using principal component analysis (PCA) and multivariate Granger causality (MVGC) techniques. Industrial & Engineering Chemistry Research, 2017, 56(25): 7260-7272 [41] Pyun H, Kim K, Ha D, Lee C J, Lee W B. Root causality analysis at early abnormal stage using principal component analysis and multivariate Granger causality. Process Safety and Environmental Protection, 2020, 135: 113-125 doi: 10.1016/j.psep.2019.12.010 [42] Cheng H C, Wu J, Liu Y Q, Huang D P. A novel fault identification and root-causality analysis of incipient faults with applications to wastewater treatment processes. Chemometrics and Intelligent Laboratory Systems, 2019, 188: 24-36 doi: 10.1016/j.chemolab.2019.03.004 [43] Faes L, Porta A, Nollo G. Testing frequency-domain causality in multivariate time series. IEEE Transactions on Biomedical Engineering, 2010, 57(8): 1897-1906 doi: 10.1109/TBME.2010.2042715 [44] Gigi S, Tangirala A K. Quantitative analysis of directional strengths in jointly stationary linear multivariate processes. Biological Cybernetics, 2010, 103: 119-133 doi: 10.1007/s00422-010-0386-6 [45] Yuan T, Qin S J. Root cause diagnosis of plant-wide oscillations using Granger causality. Journal of Process Control, 2014, 24(2): 450-459 doi: 10.1016/j.jprocont.2013.11.009 [46] Schreiber T. Measuring information transfer. Physical Review Letters, 2000, 85: 461-464 doi: 10.1103/PhysRevLett.85.461 [47] Bauer M, Cox J W, Caveness M H, Downs J J, Thornhill N F. Finding the direction of disturbance propagation in a chemical process using transfer entropy. IEEE Transactions on Control Systems Technology, 2007, 15(1): 12-21 doi: 10.1109/TCST.2006.883234 [48] Naghoosi E, Huang B, Domlan E, Kadali R. Information transfer methods in causality analysis of process variables with an industrial application. Journal of Process Control, 2013, 23(9): 1296-1305 doi: 10.1016/j.jprocont.2013.02.003 [49] Silverman B W. Density Estimation for Statistics and Data Analysis. London: Chapman & Hall, 1986. [50] Lindner B, Auret L, Bauer M. A systematic workflow for oscillation diagnosis using transfer entropy. IEEE Transactions on Control Systems Technology, 2020, 28(3): 908-919 doi: 10.1109/TCST.2019.2896223 [51] Barnett L, Barrett A B, Seth A K. Granger causality and transfer entropy are equivalent for Gaussian variables. Physical Review Letters, 2009, 103: Article No. 238701 [52] Lindner B, Auret L, Bauer M, Groenewald J W D. Comparative analysis of Granger causality and transfer entropy to present a decision flow for the application of oscillation diagnosis. Journal of Process Control, 2019, 79: 72-84 doi: 10.1016/j.jprocont.2019.04.005 [53] Shu Y D, Zhao J S. Data-driven causal inference based on a modified transfer entropy. Computers & Chemical Engineering, 2013, 57: 173-180 [54] Staniek M, Lehnertz K. Symbolic transfer entropy. Physical Review Letters, 2008, 100: Article No. 158101 [55] Duan P, Yang F, Chen T W, Shah S L. Direct causality detection via the transfer entropy approach. IEEE Transactions on Control Systems Technology, 2013, 21(6): 2052-2066 doi: 10.1109/TCST.2012.2233476 [56] Duan P, Yang F, Shah S L, Chen T W. Transfer zero-entropy and its application for capturing cause and effect relationship between variables. IEEE Transactions on Control Systems Technology, 2015, 23(3): 855-867 doi: 10.1109/TCST.2014.2345095 [57] Yu W J, Yang F. Detection of causality between process variables based on industrial alarm data using transfer entropy. Entropy, 2015, 17(8): 5868-5887 [58] Hu W K, Wang J D, Chen T W, Shah S L. Cause-effect analysis of industrial alarm variables using transfer entropies. Control Engineering Practice, 2017, 64: 205-214 doi: 10.1016/j.conengprac.2017.04.012 [59] Rashidi B, Singh D S, Zhao Q. Data-driven root-cause fault diagnosis for multivariate non-linear processes. Control Engineering Practice, 2018, 70: 134-147 doi: 10.1016/j.conengprac.2017.09.021 [60] Ma L, Dong J, Peng K X, Zhang K. A novel data-based quality-related fault diagnosis scheme for fault detection and root cause diagnosis with application to hot strip mill process. Control Engineering Practice, 2017, 67: 43-51 doi: 10.1016/j.conengprac.2017.07.005 [61] Ma L, Dong J, Peng K X. Root cause diagnosis of quality-related faults in industrial multimode processes using robust Gaussian mixture model and transfer entropy. Neurocomputing, 2018, 285: 60-73 doi: 10.1016/j.neucom.2018.01.028 [62] Zhou B F, Chioua M, Bauer M, Schlake J C, Thornhill N F. Improving root cause analysis by detecting and removing transient changes in oscillatory time series with application to a 1, 3-Butadiene process. Industrial & Engineering Chemistry Research, 2019, 58(26): 11234-11250 [63] Rashidi B, Zhao Q. Autonomous root-cause fault diagnosis using symbolic dynamic based causality analysis. Neurocomputing, 2020, 401: 10-27 doi: 10.1016/j.neucom.2020.03.007 [64] Zhang Y, Zuo H F, Bai F. Feature extraction for rolling bearing fault diagnosis by electrostatic monitoring sensors. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 229(10): 1887-1903 doi: 10.1177/0954406214550014 [65] 苏文胜, 王奉涛, 朱泓, 郭正刚, 张志新, 张洪印. 基于小波包样本熵的滚动轴承故障特征提取. 振动、测试与诊断, 2011, 31(2): 162-166 doi: 10.3969/j.issn.1004-6801.2011.02.005Su Wen-Sheng, Wang Feng-Tao, Zhu Hong, Guo Zheng-Gang, Zhang Zhi-Xin, Zhang Hong-Yin. Feature extraction of rolling element bearing fault using wavelet packet sample entropy. Journal of Vibration, Measurement & Diagnosis, 2011, 31(2): 162-166 doi: 10.3969/j.issn.1004-6801.2011.02.005 [66] Sauer T, Yorke J A, Casdagli M. Embedology. Journal of Statistical Physics, 1991, 65: 579-616 doi: 10.1007/BF01053745 [67] Bauer M, Cox J W, Caveness M H, Downs J J, Thornhill N F. Nearest neighbors methods for root cause analysis of plantwide disturbances. Industrial & Engineering Chemistry Research, 2007, 46(18): 5977-5984 [68] Stockmann M, Haber R, Schmitz U. Source identification of plant-wide faults based on k nearest neighbor time delay estimation. Journal of Process Control, 2012, 22(3): 583-598 doi: 10.1016/j.jprocont.2012.01.005 [69] 王国柱, 刘建昌, 李元, 商亮亮. 加权k最近邻重构分析的工业过程故障诊断. 控制理论与应用, 2015, 32(7): 873-880 doi: 10.7641/CTA.2015.50028Wang Guo-Zhu, Liu Jian-Chang, Li Yuan, Shang Liang-Liang. Fault diagnosis of industrial processes based on weighted k-nearest neighbor reconstruction analysis. Control Theory & Applications, 2015, 32(7): 873-880 doi: 10.7641/CTA.2015.50028 [70] Cecílio I M, Ottewill J R, Fretheim H, Thornhill N F. Removal of transient disturbances from oscillating measurements using nearest neighbors imputation. Journal of Process Control, 2016, 44: 68-78 doi: 10.1016/j.jprocont.2016.04.013 [71] Zhou Z, Wen C L, Yang C J. Fault isolation based on k-nearest neighbor rule for industrial processes. IEEE Transactions on Industrial Electronics, 2016, 63(4): 2578-2586 [72] Landman R, Jämsä-Jounela S L. Fault propagation analysis by implementing nearest neighbors method using process connectivity. IEEE Transactions on Control Systems Technology, 2019, 27(5): 2058-2067 doi: 10.1109/TCST.2018.2847651 [73] Cowell R G, Dawid P, Lauritzen S L, Spiegelhalter D J. Probabilistic Networks and Expert Systems. New York: Springer, 1999. [74] Cai B P, Huang L, Xie M. Bayesian networks in fault diagnosis. IEEE Transactions on Industrial Informatics, 2017, 13(5): 2227-2240 doi: 10.1109/TII.2017.2695583 [75] Pearl J. Probabilistic Reasoning in Intelligent Systems: Networks of Plausible Inference. San Francisco, CA: Morgan Kaufmann, 1988. [76] Yu J, Rashid M M. A novel dynamic Bayesian network-based networked process monitoring approach for fault detection, propagation identification, and root cause diagnosis. AIChE Journal, 2013, 59(7): 2348-2365 doi: 10.1002/aic.14013 [77] Dey S, Stori J A. A Bayesian network approach to root cause diagnosis of process variations. International Journal of Machine Tools and Manufacture, 2005, 45(1): 75-91 doi: 10.1016/j.ijmachtools.2004.06.018 [78] Alaeddini A, Dogan I. Using Bayesian networks for root cause analysis in statistical process control. Expert Systems With Applications, 2011, 38(9): 11230-11243 doi: 10.1016/j.eswa.2011.02.171 [79] Mori J, Mahalec V, Yu J. Identification of probabilistic graphical network model for root-cause diagnosis in industrial processes. Computers & Chemical Engineering, 2014, 71: 171-209 [80] Gharahbagheri H, Imtiaz S A, Khan F. Root cause diagnosis of process fault using KPCA and Bayesian network. Industrial & Engineering Chemistry Research, 2017, 56(8): 2054-2070 [81] Meng Q Q, Zhu Q X, Gao H H, He Y L, Xu Y. A novel scoring function based on family transfer entropy for Bayesian networks learning and its application to industrial alarm systems. Journal of Process Control, 2019, 76: 122-132 doi: 10.1016/j.jprocont.2019.01.013 [82] Chen X L, Wang J, Zhou J L. Probability density estimation and Bayesian causal analysis based fault detection and root identification. Industrial & Engineering Chemistry Research, 2018, 57(43): 14656-14664 [83] Chen G J, Ge Z Q. Hierarchical Bayesian network modeling framework for large-scale process monitoring and decision making. IEEE Transactions on Control Systems Technology, 2020, 28(2): 671-679 doi: 10.1109/TCST.2018.2882562 [84] Hu J Q, Zhang L B, Cai Z S, Wang Y, Wang A Q. Fault propagation behavior study and root cause reasoning with dynamic Bayesian network based framework. Process Safety and Environmental Protection, 2015, 97: 25-36 doi: 10.1016/j.psep.2015.02.003 [85] Wee Y Y, Cheah W P, Tan S C, Wee K. A method for root cause analysis with a Bayesian belief network and fuzzy cognitive map. Expert Systems With Applications, 2015, 42(1): 468-487 doi: 10.1016/j.eswa.2014.06.037 [86] Amin M T, Khan F, Imtiaz S. Fault detection and pathway analysis using a dynamic Bayesian network. Chemical Engineering Science, 2019, 195: 777-790 doi: 10.1016/j.ces.2018.10.024 [87] 周东华, 史建涛, 何潇. 动态系统间歇故障诊断技术综述. 自动化学报, 2014, 40(2): 161-171Zhou Dong-Hua, Shi Jian-Tao, He Xiao. Review of intermittent fault diagnosis techniques for dynamic systems. Acta Automatica Sinica, 2014, 40(2): 161-171 [88] 桂卫华, 陈晓方, 阳春华, 谢永芳. 知识自动化及工业应用. 中国科学: 信息科学, 2016, 46(8): 1016-1034 doi: 10.1360/N112016-00065Gui Wei-Hua, Chen Xiao-Fang, Yang Chun-Hua, Xie Yong-Fang. Knowledge automation and its industrial application. Scientia Sinica Informationis, 2016, 46(8): 1016-1034 doi: 10.1360/N112016-00065 [89] 文成林, 吕菲亚, 包哲静, 刘妹琴. 基于数据驱动的微小故障诊断方法综述. 自动化学报, 2016, 42(9): 1285-1299Wen Cheng-Lin, Lv Fei-Ya, Bao Zhe-Jing, Liu Mei-Qin. A review of data driven-based incipient fault diagnosis. Acta Automatica Sinica, 2016, 42(9): 1285-1299 [90] 彭开香, 马亮, 张凯. 复杂工业过程质量相关的故障检测与诊断技术综述. 自动化学报, 2017, 43(3): 349-365Peng Kai-Xiang, Ma Liang, Zhang Kai. Review of quality-related fault detection and diagnosis techniques for complex industrial processes. Acta Automatica Sinica, 2017, 43(3): 349-365 [91] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931-1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Acta Automatica Sinica, 2018, 44(11): 1931-1943 [92] 赵春晖, 余万科, 高福荣. 非平稳间歇过程数据解析与状态监控——回顾与展望. 自动化学报, 2020, 46(10): 2072-2091Zhao Chun-Hui, Yu Wan-Ke, Gao Fu-Rong. Data analytics and condition monitoring methods for nonstationary batch processes-current status and future. Acta Automatica Sinica, 2020, 46(10): 2072-2091 [93] 何潇, 郭亚琦, 张召, 贾繁林, 周东华. 动态系统的主动故障诊断技术. 自动化学报, 2020, 46(8): 1557-1570He Xiao, Guo Ya-Qi, Zhang Zhao, Jia Fan-Lin, Zhou Dong-Hua. Active fault diagnosis for dynamic systems. Acta Automatica Sinica, 2020, 46(8): 1557-1570 [94] Thambirajah J, Benabbas L, Bauer M, Thornhill N F. Cause-and-effect analysis in chemical processes utilizing XML, plant connectivity and quantitative process history. Computers & Chemical Engineering, 2009, 33(2): 503-512 [95] Yang F, Shah S L, Xiao D Y. Signed directed graph based modeling and its validation from process knowledge and process data. International Journal of Applied Mathematics and Computer Science, 2012, 22(1): 41-53 doi: 10.2478/v10006-012-0003-z [96] Suresh R, Sivaram A, Venkatasubramanian V. A hierarchical approach for causal modeling of process systems. Computers & Chemical Engineering, 2019, 123: 170-183(本条文献与第17条文献重复, 请联系作者确认) [97] Gao H H, Xu Y, Gu X B, Lin X Y, Zhu Q X. Systematic rationalization approach for multivariate correlated alarms based on interpretive structural modeling and Likert scale. Chinese Journal of Chemical Engineering, 2015, 23(12): 1987-1996 doi: 10.1016/j.cjche.2015.11.009 [98] He B, Chen T, Yang X H. Root cause analysis in multivariate statistical process monitoring: Integrating reconstruction-based multivariate contribution analysis with fuzzy-signed directed graphs. Computers & Chemical Engineering, 2014, 64: 167-177 [99] Namaki-Shoushtari O, Huang B. Bayesian control loop diagnosis by combining historical data and process knowledge of fault signatures. IEEE Transactions on Industrial Electronics, 2015, 62(6): 3696-3704 [100] Luo L J, Bao S Y, Mao J F, Ding Z Y. Industrial process monitoring based on knowledge-data integrated sparse model and two-level deviation magnitude plots. Industrial & Engineering Chemistry Research, 2018, 57(2): 611-622 [101] Don M G, Khan F. Dynamic process fault detection and diagnosis based on a combined approach of hidden Markov and Bayesian network model. Chemical Engineering Science, 2019, 201: 82-96 doi: 10.1016/j.ces.2019.01.060 [102] Zhu Q X, Meng Q Q, Wang P J, He Y L. Novel causal network modeling method integrating process knowledge with modified transfer entropy: A case study of complex chemical processes. Industrial & Engineering Chemistry Research, 2017, 56(48): 14282-14289 [103] Gao H H, Xu Y, Zhu Q X. Spatial interpretive structural model identification and AHP-based multimodule fusion for alarm root-cause diagnosis in chemical processes. Industrial & Engineering Chemistry Research, 2016, 55(12): 3641-3658 [104] Zhu Q X, Luo Y, He Y L. Novel distributed alarm visual analysis using multicorrelation block-based PLS and its application to online root cause analysis. Industrial & Engineering Chemistry Research, 2019, 58(45): 20655-20666 [105] Landman R, Kortela J, Sun Q, Jämsä-Jounela S L. Fault propagation analysis of oscillations in control loops using data-driven causality and plant connectivity. Computers & Chemical Engineering, 2014, 71: 446-456 [106] Landman R, Jämsä-Jounela S L. Hybrid approach to casual analysis on a complex industrial system based on transfer entropy in conjunction with process connectivity information. Control Engineering Practice, 2016, 53: 14-23 doi: 10.1016/j.conengprac.2016.04.010 [107] Landman R, Jämsä-Jounela S L. Hybrid causal analysis combining a nonparametric multiplicative regression causality estimator with process connectivity information. Control Engineering Practice, 2019, 93: Article No. 104140 [108] Ma L, Dong J, Peng K X. A practical propagation path identification scheme for quality-related faults based on nonlinear dynamic latent variable model and partitioned Bayesian network. Journal of the Franklin Institute, 2018, 355(15): 7570-7594 doi: 10.1016/j.jfranklin.2018.07.035 [109] Ma L, Dong J, Peng K X, Zhang C F. Hierarchical monitoring and root-cause diagnosis framework for key performance indicator-related multiple faults in process industries. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2091-2100 doi: 10.1109/TII.2018.2855189 [110] Ma L, Dong J, Peng K X. A novel hierarchical detection and isolation framework for quality-related multiple faults in large-scale processes. IEEE Transactions on Industrial Electronics, 2020, 67(2): 1316-1327 doi: 10.1109/TIE.2019.2898576 -

下载:

下载: