Two-dimensional Prediction for Silicon Content of Hot Metal of Blast Furnace Based on Bootstrap

-

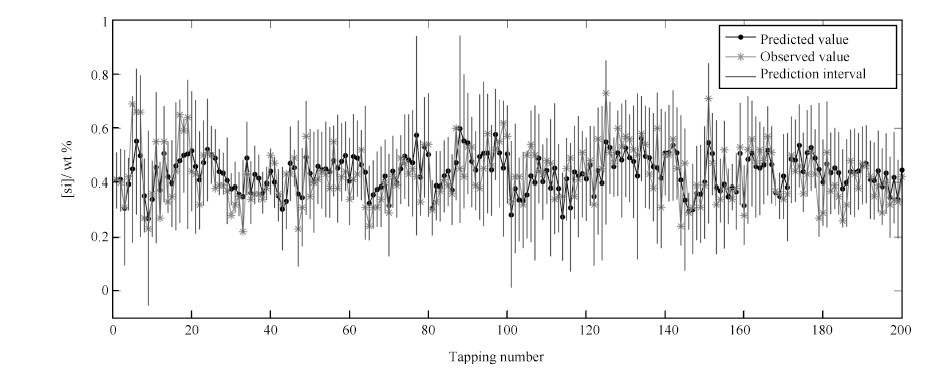

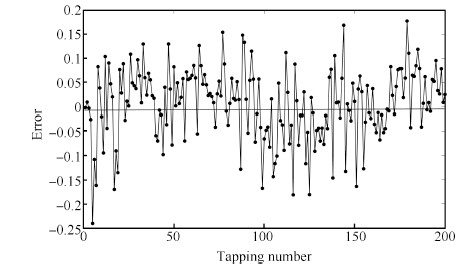

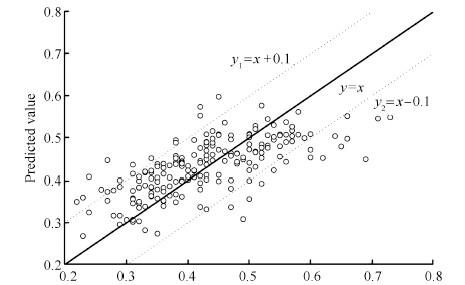

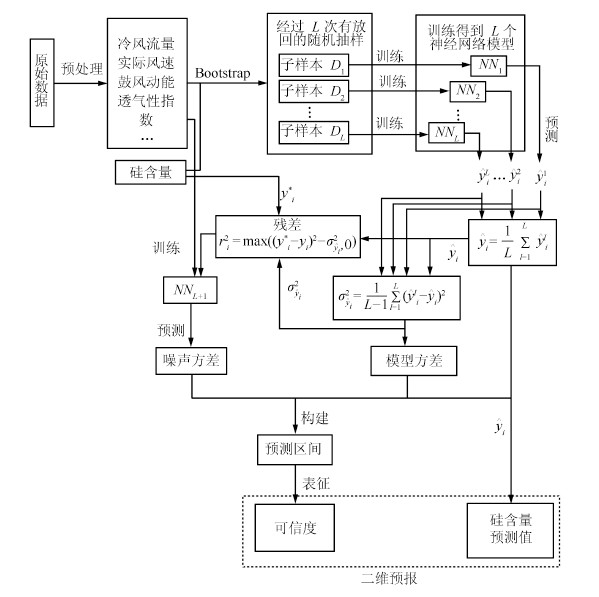

摘要: 高炉铁水硅含量的实时准确预报对调控高炉炉温和稳定炉况具有重要作用, 但其预报结果一直存在准确度不高和缺乏可信度表征等问题, 特别是在炉况不稳、运行数据波动较大时, 预报结果的准确度和可信度急速下降, 不利于现场操作人员根据预报结果进行生产操作. 为此本文融合神经网络和Bootstrap预报区间方法, 构建高炉铁水硅含量的二维预报模型, 实现在预报硅含量值的同时给出了该预测值的可信度.应用实例表明, 本文提出的方法提高了硅含量点预测结果的准确度, 且预测区间宽度能正确地表征点预测结果的可信度, 对实际生产操作具有较好的指导意义.Abstract: Accurate real-time forecasting of silicon content in hot metal of blast furnace plays a significant role in furnace temperature regulation, but the prediction results have a low hit rate and lack any indication of accuracy. Especially when furnace conditions are unstable and the data fluctuate frequently, the hit rate and the reliability decrease so sharply that workers cannot use the prediction results for manufacturing operation. Therefore, a two-dimensional prediction model of silicon content in hot metal based on the integration of Bootstrap method and neural network is constructed to predict the silicon content. Meanwhile, the reliability of point prediction is also provided. Application results show that not only does the model improve the prediction accuracy of silicon content in point shooting, but also the prediction interval width correctly characterizes the reliability of point prediction. The proposed method will be beneficial to the practical production process.

-

Key words:

- Blast furnace /

- Bootstrap /

- two-dimensional prediction /

- prediction interval /

- reliability

-

表 1 模型的候选输入变量

Table 1 List of candidate input variables of the model

变量名 单位 变量名 单位 Si(n-1) wt % 理论燃烧温度 ℃ Si(n - 2) wt % 矿焦比 kg/t 料速 t/h 标准风速 m/s 顶压 kpa 热风温度 oC 全压差 kpa 鼓风动能 kg . m/s 富氧率 wt % 冷风流量 m3/ min 热风压力 kpa 冷风压力 kpa 实际风速 m/s 富氧压力 kpa 喷煤量 t 透气性指数 m3/ min .kpa 表 2 模型的输入变量

Table 2 List of the input variables of the model

变量名 相关性 变量名 相关性 Si(n - 1) 0.731 富氧率 0.251 Si(n - 2) 0.618 热风温度 -0.214 冷风流量 0.378 料速 -0.207 实际风速 -0.342 透气性指数 -0.113 鼓风动能 -0.304 表 3 四种预测模型的硅含量值的预测结果对比

Table 3 Comparison of prediction results of the four models

方法 命中率(%) 均方根误差 单一神经网络 75 0.1251 偏最小二乘模型 70 0.1384 ARIMA模型 73 0.1297 二维预报模型 84 0.0735 表 4 二维预报模型的预测结果统计

Table 4 Statistics of prediction results of the two-dimensional

绝对误差 预测点个数 预测区间平均宽度 <0.05 101 0.3118 (0.05, 0.1) 67 0.3207 < 0.1 32 0.4744 表 5 硅含量预测区间宽度和点预测结果的可信度关系

Table 5 The relationship between width of prediction interval and reliability of point predictions

预测点个数 预测区间 预测区间宽度范围 < 0.1 < 0.1 共 可信度(%) Ri < 0.3 76 4 80 95% R2 (0.3, 0.45) 77 3 80 96.25% Rs < 0.45 15 25 40 37.5% -

[1] de Castro J A, Nogami H, Yagi J I. Transient mathematical model of blast furnace based on multi-fluid concept with application to high PCI operation. ISIJ International, 2000, 40(7): 637-646 [2] Nogami H, Chu M S, Yagi J I. Multi-dimensional transient mathematical simulator of blast furnace process based on multi-fluid and kinetic theories. Computers and Chemical Engineering, 2005, 29(11-12): 2438-2448 [3] Gao C H, Ge Q H, Jian L. Rule extraction from fuzzy-based blast furnace SVM multiclassifier for decision-making. IEEE Transactions on Fuzzy Systems, 2014, 22(3): 586-596 [4] 黄龙诚. 基于机理与数据混合驱动的高炉分布式炉温建模方法研究[硕士学位论文], 浙江大学, 中国, 2013Huang Long-Cheng. Blast Furnace Distributed Temperature Modeling Method Research Based on Mechanism and Data Hybrid Driven [Master dissertation], Zhejiang University, China, 2013 [5] 李志玲. 基于主成分分析和偏最小二乘的高炉炉温预测模型的研究[硕士学位论文], 内蒙古科技大学, 中国, 2011Li Zhi-Ling. Study for Prediction Model of Blast Furnace Temperture Based on Principal Component Analysis and Partial Least Squares [Master dissertation], Inner Mongolia University of Science & Technology, China, 2011 [6] 王文慧. 基于小波分析理论的高炉炉温预测模型研究[硕士学位论文], 浙江大学, 中国, 2005Wang Wen-Hui. Study for Prediction Model of Silicon Content in Molten Iron Based on Wavelet Analysis [Master dissertation], Zhejiang University, China, 2005 [7] Chen W, Wang B X, Han H L. Prediction and control for silicon content in pig iron of blast furnace by integrating artificial neural network with genetic algorithm. Ironmaking & Steelmaking, 2010, 37(6): 458-463 [8] Zeng J S, Gao C H, Liu X G, Yang K P, Luo S H. Using non-linear GARCH model to predict silicon content in blast furnace hot metal. Asian Journal of Control, 2008, 10(6): 632-637 [9] Saxén H, Pettersson F, Gunturu K. Evolving nonlinear time-series models of the hot metal silicon content in the blast furnace. Materials and Manufacturing Processes, 2007, 22(5): 577-584 [10] 刘学艺, 刘祥官, 王文慧. 贝叶斯网络在高炉铁水硅含量预测中的应用. 钢铁, 2005, 40(3): 17-20Liu Xue-Yi, Liu Xiang-Guan, Wang Wen-Hui. Application of Bayesian network to predicting silicon content in hot metal. Iron and Steel, 2005, 40(3): 17-20 [11] Gao C H, Jian L, Luo S H. Modeling of the thermal state change of blast furnace hearth with support vector machines. IEEE Transactions on Industrial Electronics, 2012, 59(2): 1134-1145 [12] Jian L, Gao C H, Li L, Zeng J S. Application of least squares support vector machines to predict the silicon content in blast furnace hot metal. ISIJ international, 2008, 48(11): 1659-1661 [13] Gao C H, Zhou Z M, Qian J X. Chaotic identification and prediction of silicon content in hot metal. Journal of Iron and Steel Research International, 2005, 12(5): 3-5, 46 [14] 郜传厚, 渐令, 陈积明, 孙优贤. 复杂高炉炼铁过程的数据驱动建模及预测算法. 自动化学报, 2009, 35(6): 725-730Gao Chuan-Hou, Jian Ling, Chen Ji-Ming, Sun You-Xian. Data-driven modeling and predictive algorithm for complex blast furnace ironmaking process. Acta Automatica Sinica, 2009, 35(6): 725-730 [15] 南晓强, 李群湛, 赵元哲, 邱大强. 计及风电预测可信度的经济调度及辅助决策方法. 电力系统自动化, 2013, 37(19): 61-67Nan Xiao-Qiang, Li Quan-Zhan, Zhao Yuan-Zhe, Qiu Da-Qiang. An economic dispatch and decision making method based on credibility of wind power forecasting. Automation of Electric Power Systems, 2013, 37(19): 61-67 [16] Zhao T T, Wang Q J, Bennett J C, Robertson D E, Shao Q X, Zhao J S. Quantifying predictive uncertainty of streamflow forecasts based on a Bayesian joint probability model. Journal of Hydrology, 2015, 528: 329-340 [17] Khosravi A, Nahavandi S, Creighton D, Atiya A F. Comprehensive review of neural network-based prediction intervals and new advances. IEEE Transactions on Neural Networks, 2011, 22(9): 1341-1356 [18] Chernick M R. Bootstrap Methods: A Guide for Practitioners and Researchers (Second Edition). Hoboken, N.J.: Wiley-Interscience, 2011. [19] 杨甲沛, 李锵, 刘郑, 袁晓琳. 基于自适应学习速率的改进型BP算法研究. 计算机工程与应用, 2009, 45(11): 56-58Yang Jia-Pei, Li Qiang, Liu Zheng, Yuan Xiao-Lin. Research of improved BP algorithm based on self-adaptive learning rate. Computer Engineering and Applications, 2009, 45(11): 56-58 [20] Nix D A, Weigend A S. Estimating the mean and variance of the target probability distribution. In: Proceedings of the 1994 IEEE World Congress on Computational Intelligence, 1994 IEEE International Conference on Neural Networks. Orlando, FL: IEEE, 1994. 55-60 -

下载:

下载: