-

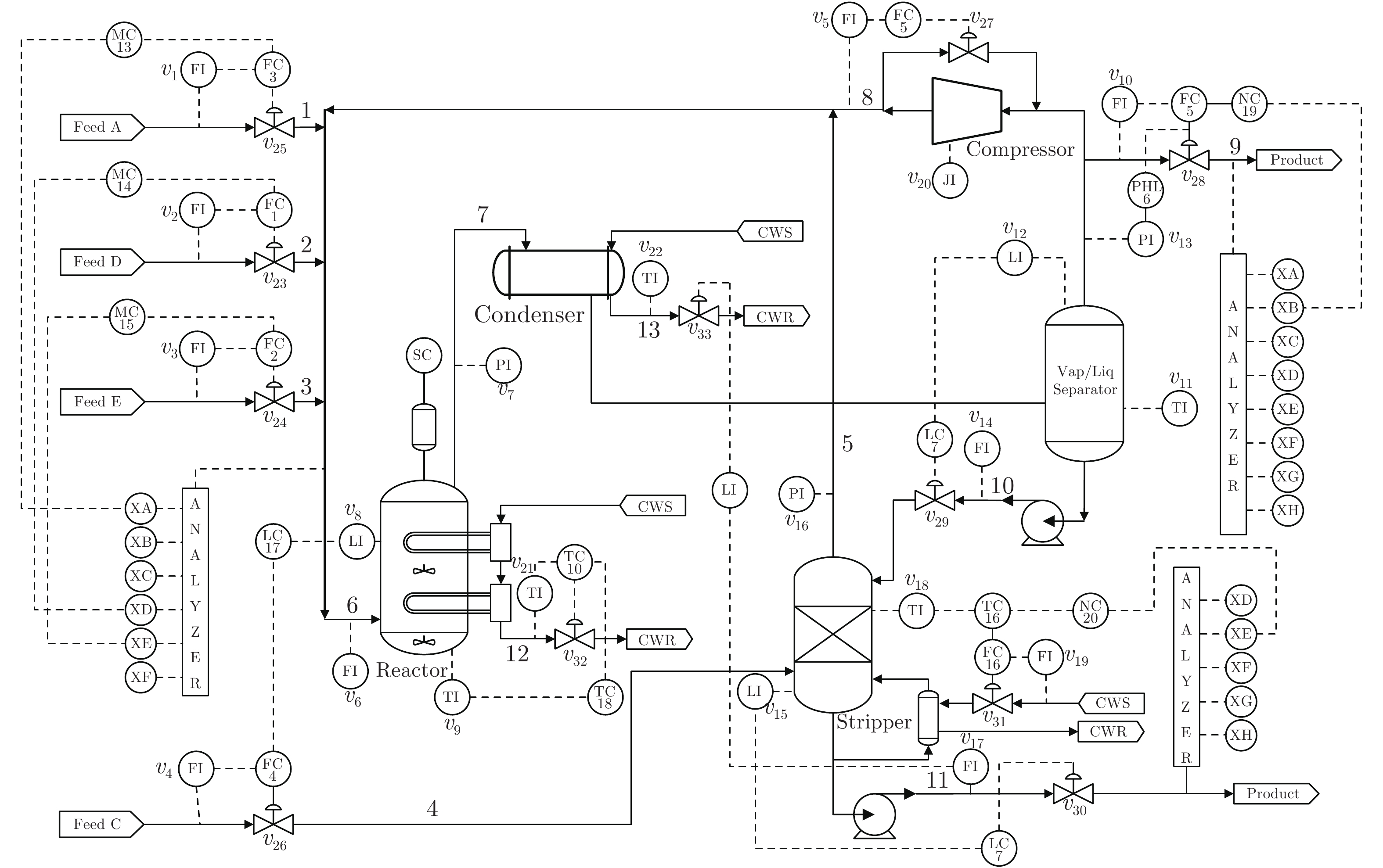

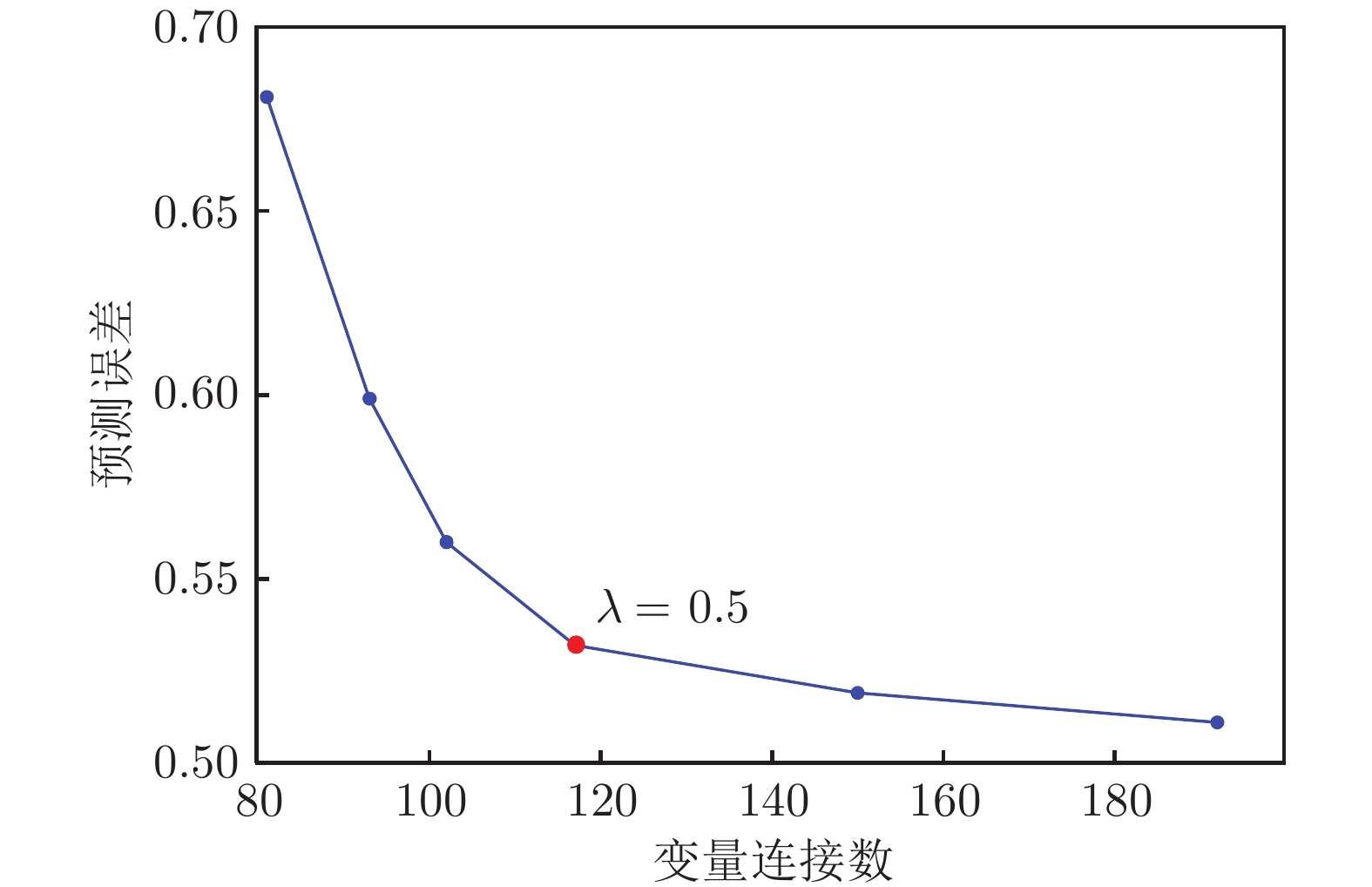

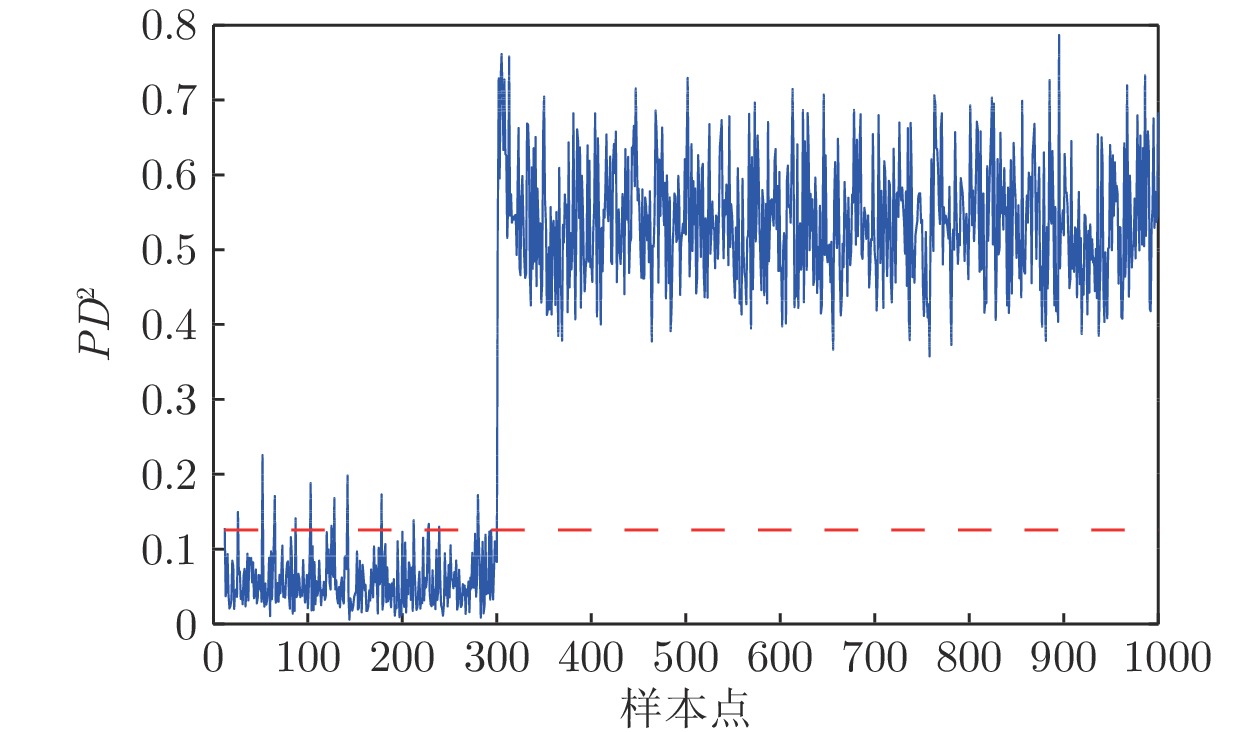

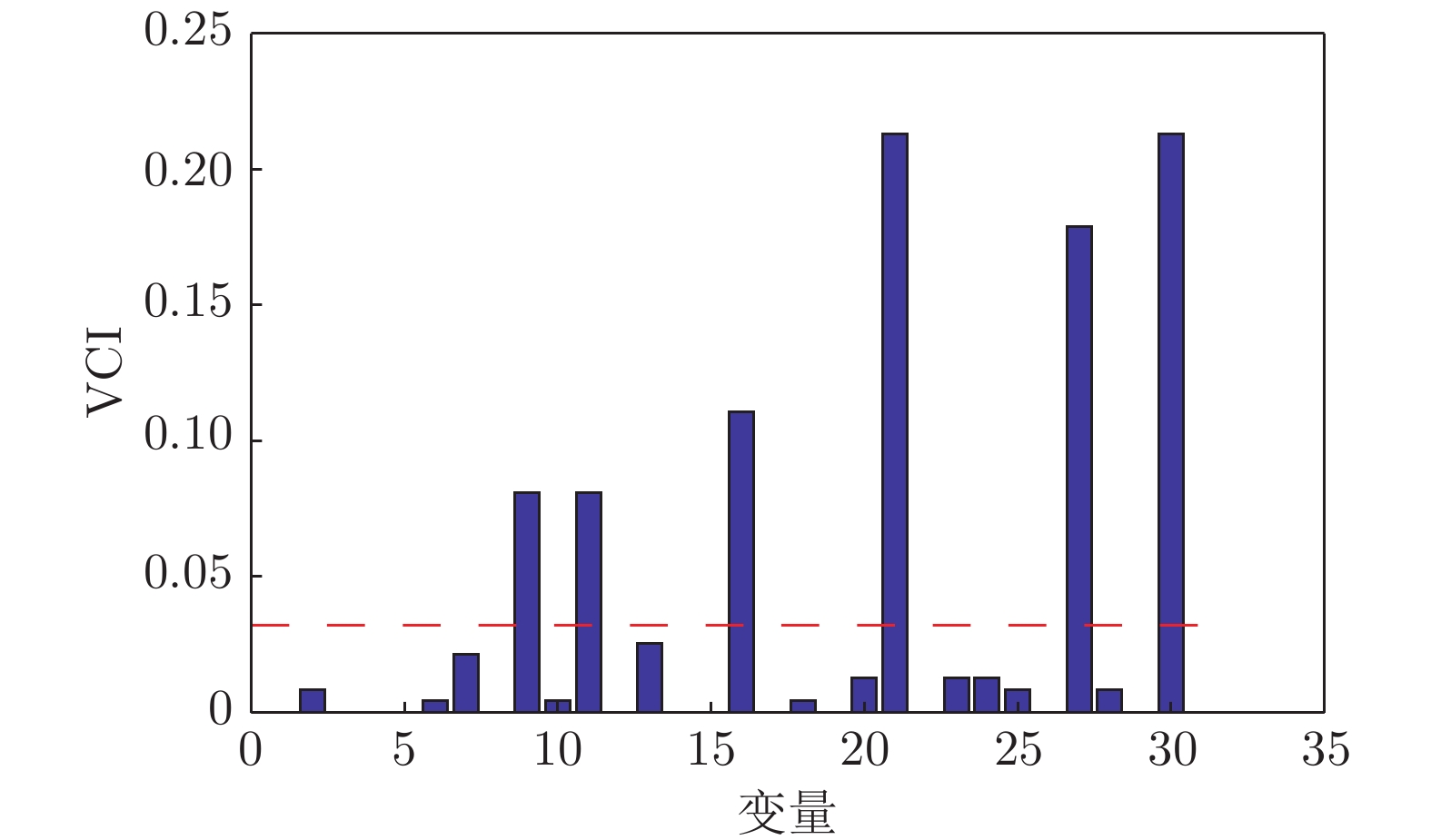

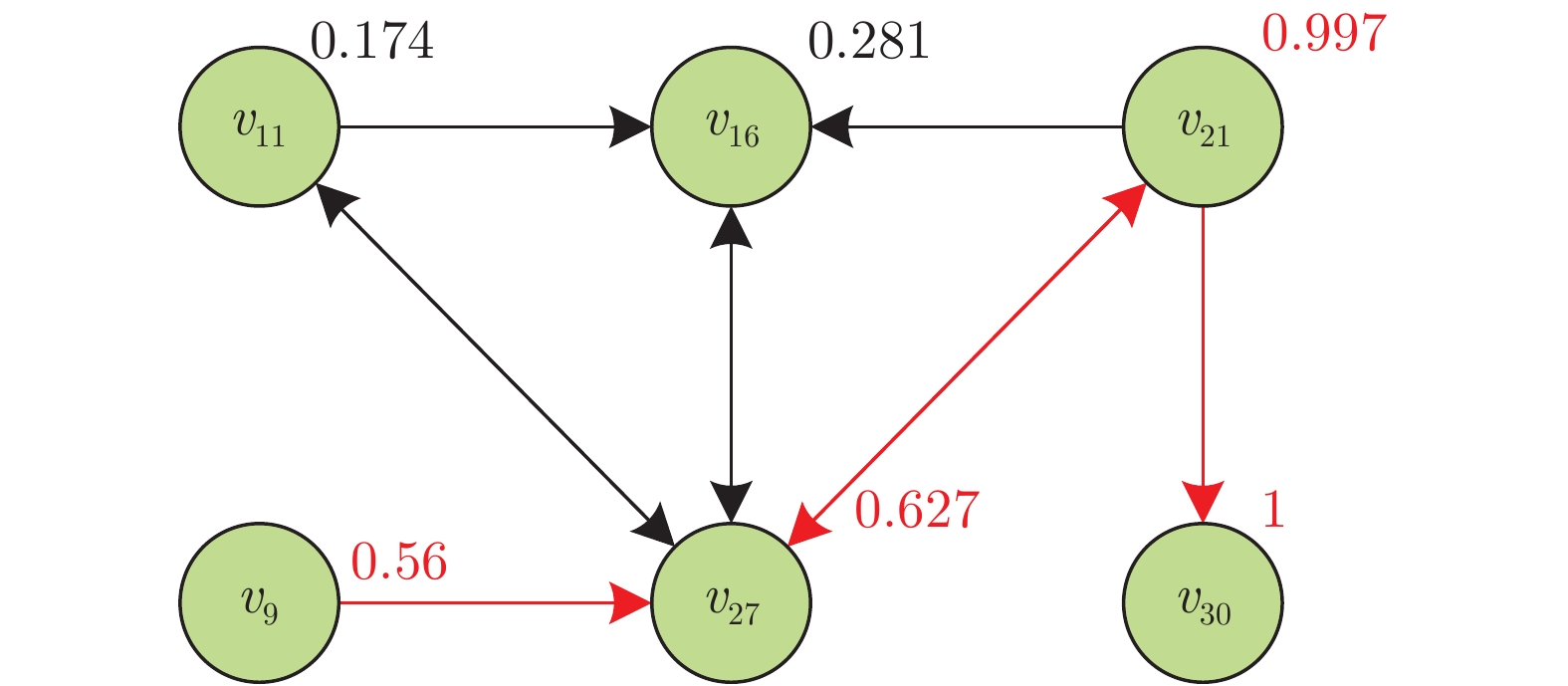

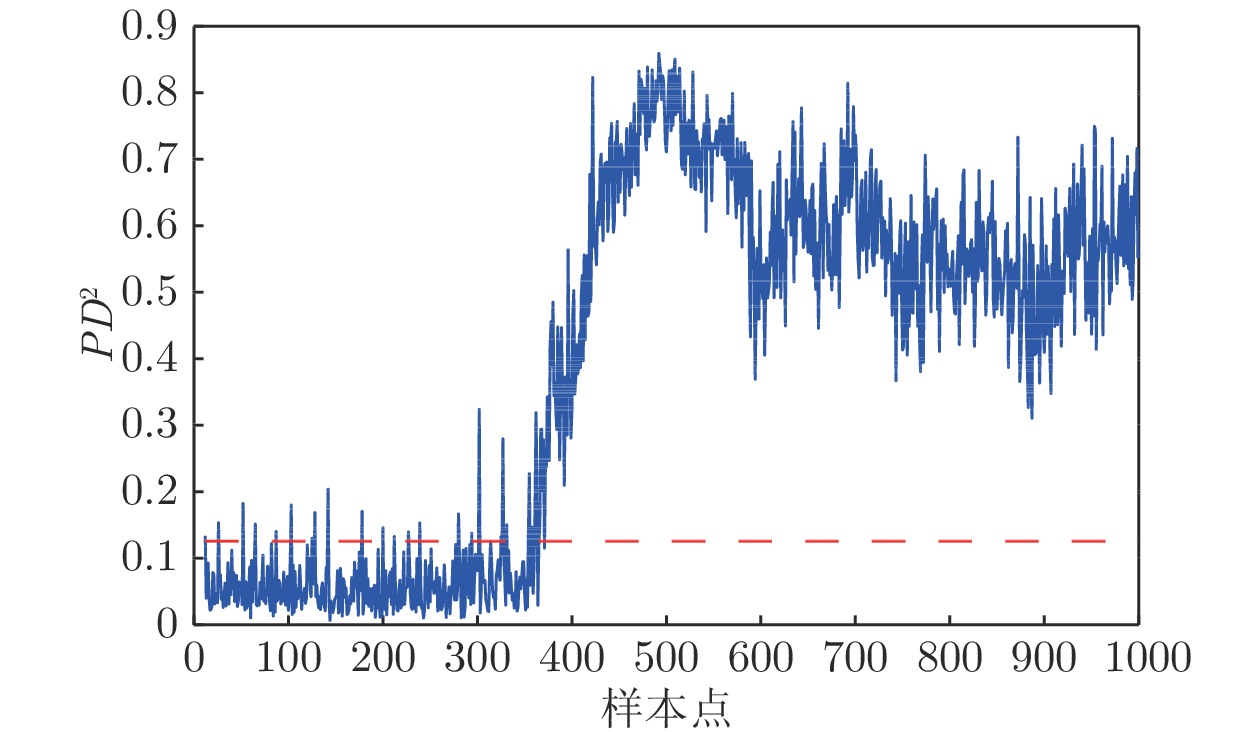

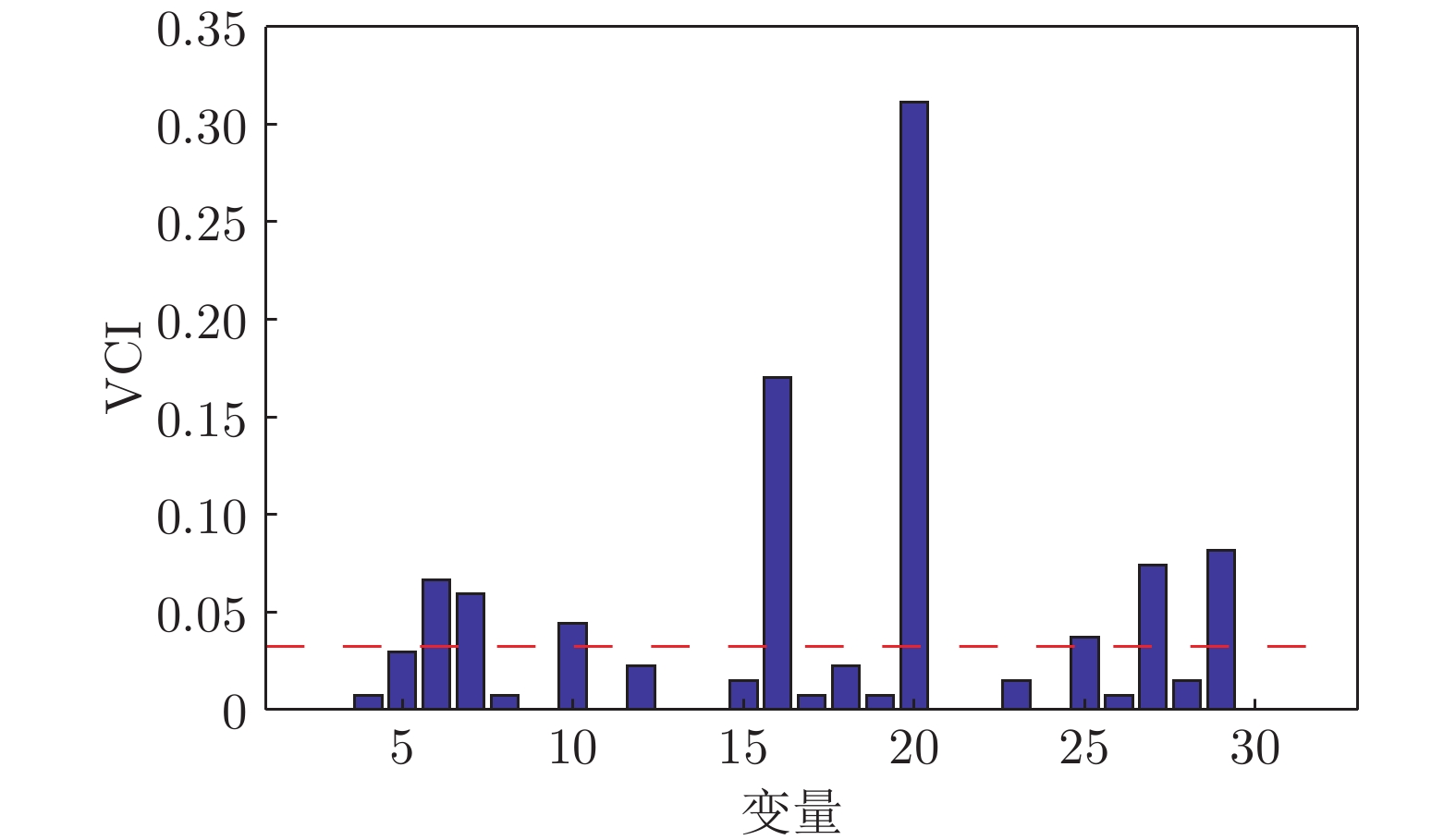

摘要: 为了实现复杂工业过程故障检测和诊断一体化建模, 提出了一种新颖的深度因果图建模方法. 首先, 利用循环神经网络建立深度因果图模型, 将Group Lasso稀疏惩罚项引入到模型训练中, 自动地检测过程变量间的因果关系. 其次, 利用模型学习到的条件概率预测模型对每个变量建立监测指标, 并融合得到综合指标进行整体工业过程故障检测. 一旦检测到故障, 对故障样本构建变量贡献度指标, 隔离故障相关变量, 并通过深度因果图模型的局部因果有向图诊断故障根源, 辨识故障传播路径. 最后, 通过田纳西−伊斯曼过程进行仿真验证, 实验结果验证了所提方法的有效性.

-

关键词:

- 深度因果图模型 /

- 故障检测 /

- 根源诊断 /

- 传播路径辨识 /

- Group Lasso

Abstract: To achieve integrative modeling of fault detection and diagnosis for complex industrial process, this paper proposes a novel deep causality graph modeling method. The deep causality graph model is constructed based on recurrent neural network. Group Lasso sparse penalty term is introduced into model training to detect the causality among process variables automatically. Then the conditional probability prediction models learned from deep causality graph model are used to establish single variable monitoring index for each process variable. An integrated global monitoring index is obtained for fault detection in the whole industrial process. Once fault is detected, the variable contribution indexes are built to isolate fault-related variables, and the local causality directed graph network built by fault-related variables is used for root cause diagnosis and propagation pathway identification. Finally, the proposed framework is simulated by the Tennessee Eastman benchmark process data. The experimental results verify the effectiveness of the proposed method. -

表 1 TE过程的因果矩阵

Table 1 The causality matrix of TE process

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 3 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 4 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 6 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 7 0 0 0 0 0 0 0 0 0 0 1 0 1 0 0 1 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 8 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 9 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 0 0 0 0 0 0 0 0 10 0 0 0 0 0 0 1 0 0 0 0 0 1 0 0 1 0 0 0 0 0 1 0 0 0 0 1 0 0 0 0 11 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 1 12 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 13 0 0 0 0 0 0 1 0 0 0 1 0 0 0 0 1 0 0 0 1 1 1 1 1 0 1 1 0 0 0 0 14 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 15 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 16 0 0 0 0 0 0 1 0 0 0 1 0 1 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 17 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 18 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 1 1 0 0 0 1 0 1 0 0 0 19 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 20 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 1 0 1 0 0 0 0 0 0 0 1 1 0 0 0 0 21 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 0 1 1 0 1 1 1 0 0 0 0 22 0 0 0 0 0 0 1 0 0 0 1 0 1 0 0 1 0 1 0 1 0 0 0 0 0 1 1 0 0 0 1 23 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 1 0 0 24 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 1 0 0 25 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 26 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 1 0 0 27 0 0 0 0 0 0 0 0 1 0 1 0 1 0 0 1 0 0 0 1 1 1 1 1 1 1 0 0 0 0 1 28 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 1 0 0 0 0 0 0 1 0 0 29 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 0 1 0 0 0 0 0 0 0 0 0 0 0 30 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 31 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 表 2 21个故障类型的FDRs (%)

Table 2 The FDRs of 21 faults (%)

Fault 1 2 3 4 5 6 7 8 FDR 99.1 96.9 15.1 100 4.1 100 100 92.4 Fault 9 10 11 12 13 14 15 16 FDR 11.9 81 97.1 29 93.6 99.4 6.6 42.9 Fault 17 18 19 20 21 — — — FDR 86.1 69.4 95.6 89.9 4.7 — — — -

[1] 赵春晖, 余万科, 高福荣. 非平稳间歇过程数据解析与状态监控—回顾与展望. 自动化学报, 2020, 46(10): 2072-2091Zhao Chun-Hui, Yu Wan-Ke, Gao Fu-Rong. Data analytics and condition monitoring methods for nonstationary batch processes — current status and future. Acta Automatica Sinica, 2020, 46(10): 2072-2091 [2] Dong Y N, Qin S J. A novel dynamic PCA algorithm for dynamic data modeling and process monitoring. Journal of Process Control, 2018, 67: 1-11 doi: 10.1016/j.jprocont.2017.05.002 [3] 周平, 刘记平, 梁梦圆, 张瑞垚. 基于KPLS鲁棒重构误差的高炉燃料比监测与异常识别. 自动化学报, 2021, 47(7): 1661-1671Zhou Ping, Liu Ji-Ping, Liang Meng-Yuan, Zhang Rui-Yao. KPLS Robust reconstruction error based monitoring and anomaly identification of fuel ratio in blast furnace ironmaking. Acta Automatica Sinica, 2021, 47(7): 1661-1671 [4] Zhu J L, Ge Z Q, Song Z H. Non-Gaussian industrial process monitoring with probabilistic independent component analysis. IEEE Transactions on Automation Science and Engineering, 2017, 14(2): 1309-1319 doi: 10.1109/TASE.2016.2537373 [5] Yang J, Dong J T, Shi H B, Tan S. Quality monitoring method based on enhanced canonical component analysis. ISA Transactions, 2020, 105: 221-229 doi: 10.1016/j.isatra.2020.06.008 [6] Wang K, Chen J H, Song Z H. A sparse loading-based contribution method for multivariate control performance diagnosis. Journal of Process Control, 2020, 85: 199-213 doi: 10.1016/j.jprocont.2019.12.001 [7] Alcala C F, Qin S J. Analysis and generalization of fault diagnosis methods for process monitoring. Journal of Process Control, 2011, 21(3): 322-330 doi: 10.1016/j.jprocont.2010.10.005 [8] Van Den Kerkhof P, Vanlaer J, Gins G, Van Impe J F M. Analysis of smearing-out in contribution plot based fault isolation for statistical process control. Chemical Engineering Science, 2013, 104: 285-293 doi: 10.1016/j.ces.2013.08.007 [9] 尹进田, 谢永芳, 陈志文, 彭涛, 杨超. 基于故障传播与因果关系的故障溯源方法及其在牵引传动控制系统中的应用. 自动化学报, 2020, 46(1): 47-57Yin Jin-Tian, Xie Yong-Fang, Chen Zhi-Wen, Peng Tao, Yang Chao. Fault tracing method based on fault propagation and causality with its application to the traction drive control system. Acta Automatica Sinica, 2020, 46(1): 47-57 [10] Ma L, Dong J, Peng K X. Root cause diagnosis of quality-related faults in industrial multimode processes using robust Gaussian mixture model and transfer entropy. Neurocomputing, 2018, 285: 60-73 doi: 10.1016/j.neucom.2018.01.028 [11] Li Z C, Tian L, Jiang Q C, Yan X F. Distributed-ensemble stacked autoencoder model for non-linear process monitoring. Information Sciences, 2021, 542: 302-316 doi: 10.1016/j.ins.2020.06.062 [12] Tang P, Peng K X, Zhang K, Chen Z W, Yang X, Li L L. A deep belief network-based fault detection method for nonlinear processes. IFAC-PapersOnLine, 2018, 51(24): 9-14 doi: 10.1016/j.ifacol.2018.09.522 [13] Zhang Z H, Jiang T, Zhan C J, Yang Y P. Gaussian feature learning based on variational autoencoder for improving nonlinear process monitoring. Journal of Process Control, 2019, 75: 136-155 doi: 10.1016/j.jprocont.2019.01.008 [14] Chen X L, Wang J, Zhou J L. Probability density estimation and Bayesian causal analysis based fault detection and root identification. Industrial & Engineering Chemistry Research, 2018, 57(43): 14656-14664 [15] Chen X L, Wang J, Zhou J L. Process monitoring based on multivariate causality analysis and probability inference. IEEE Access, 2018, 6: 6360-6369 doi: 10.1109/ACCESS.2018.2795535 [16] Zerrouki H, Estrada-Lugo H D, Smadi H, Patelli E. Applications of Bayesian networks in chemical and process industries: A review. In: Proceedings of the 29th European Safety and Reliability Conference. Hannover, Germany: ESREL 2019, 2020. 3122−3129 [17] Mehranbod N, Soroush M, Piovoso M, Ogunnaike B A. Probabilistic model for sensor fault detection and identification. AIChE Journal, 2003, 49(7): 1787-1802 doi: 10.1002/aic.690490716 [18] Mehranbod N, Soroush M, Panjapornpon C. A method of sensor fault detection and identification. Journal of Process Control, 2005, 15(3): 321-339 doi: 10.1016/j.jprocont.2004.06.009 [19] Azhdari M, Mehranbod N. Application of Bayesian belief networks to fault detection and diagnosis of industrial processes. In: Proceedings of the 2010 International Conference on Chemistry and Chemical Engineering. Kyoto, Japan: IEEE, 2010. 92−96 [20] Gonzalez R, Huang B, Lau E. Process monitoring using kernel density estimation and Bayesian networking with an industrial case study. ISA Transactions, 2015, 58: 330-347 doi: 10.1016/j.isatra.2015.04.001 [21] Chen G J, Ge Z Q. Hierarchical Bayesian network modeling framework for large-scale process monitoring and decision making. IEEE Transactions on Control Systems Technology, 2020, 28(2): 671-679 doi: 10.1109/TCST.2018.2882562 [22] Chen G J, Ge Z Q. Robust Bayesian networks for low-quality data modeling and process monitoring applications. Control Engineering Practice, 2020, 97: Article No. 104344 doi: 10.1016/j.conengprac.2020.104344 [23] Yu J, Rashid M M. A novel dynamic Bayesian network-based networked process monitoring approach for fault detection, propagation identification, and root cause diagnosis. AIChE Journal, 2013, 59(7): 2348-2365 doi: 10.1002/aic.14013 [24] Zhang Z D, Dong F L. Fault detection and diagnosis for missing data systems with a three time-slice dynamic Bayesian network approach. Chemometrics and Intelligent Laboratory Systems, 2014, 138: 30-40 doi: 10.1016/j.chemolab.2014.07.009 [25] Chung J, Gulcehre C, Cho K, Bengio Y. Empirical evaluation of gated recurrent neural networks on sequence modeling. arXiv preprint arXiv: 1412.3555, 2014 [26] Yuan M, Lin Y. Model selection and estimation in regression with grouped variables. Journal of the Royal Statistical Society: Series B (Statistical Methodology), 2006, 68(1): 49-67 doi: 10.1111/j.1467-9868.2005.00532.x -

下载:

下载: