Multi-objective Optimization Algorithm for Non-linear Manufacturing Process Based on Three-tier Virtual Workflow Model

-

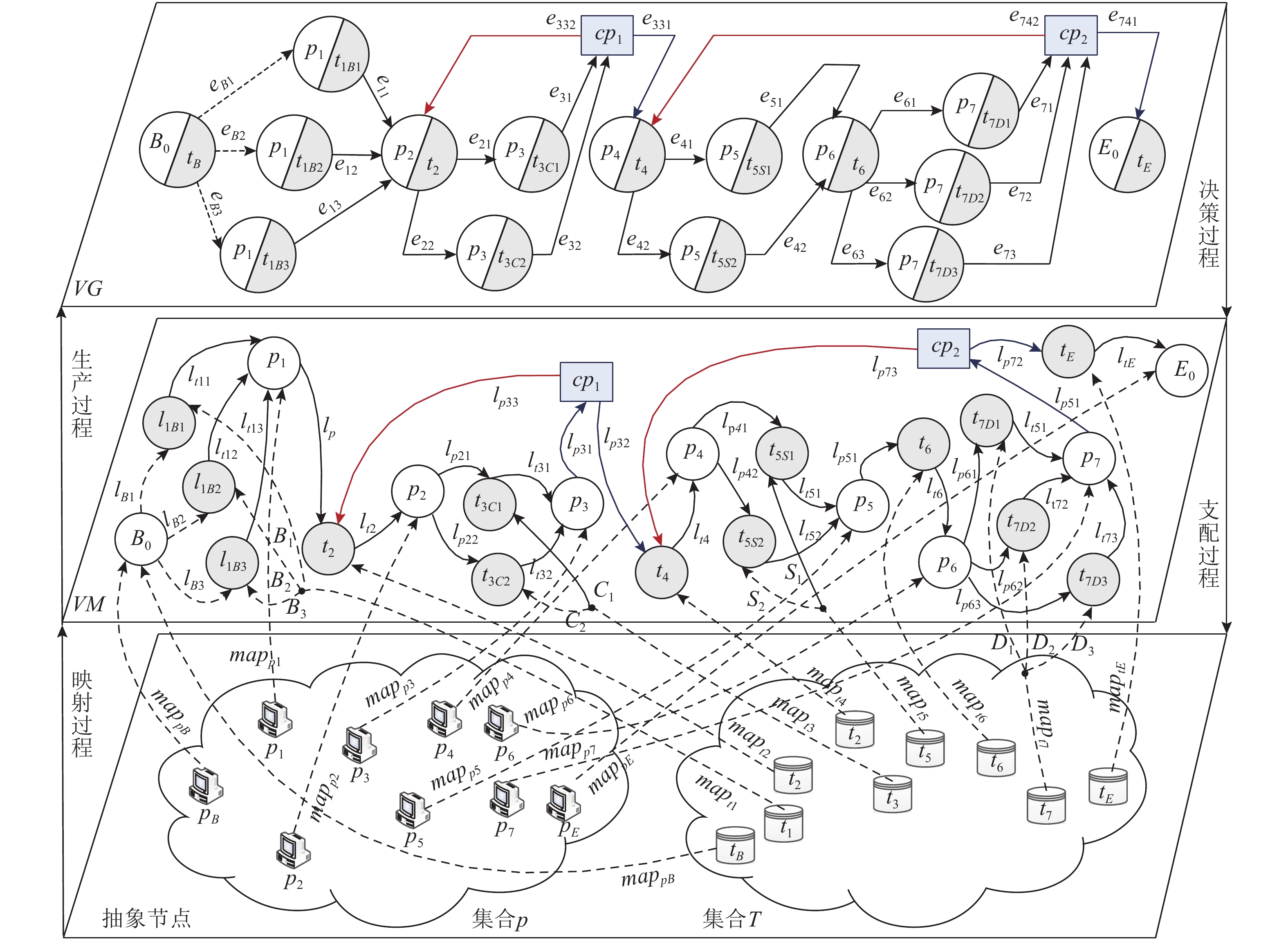

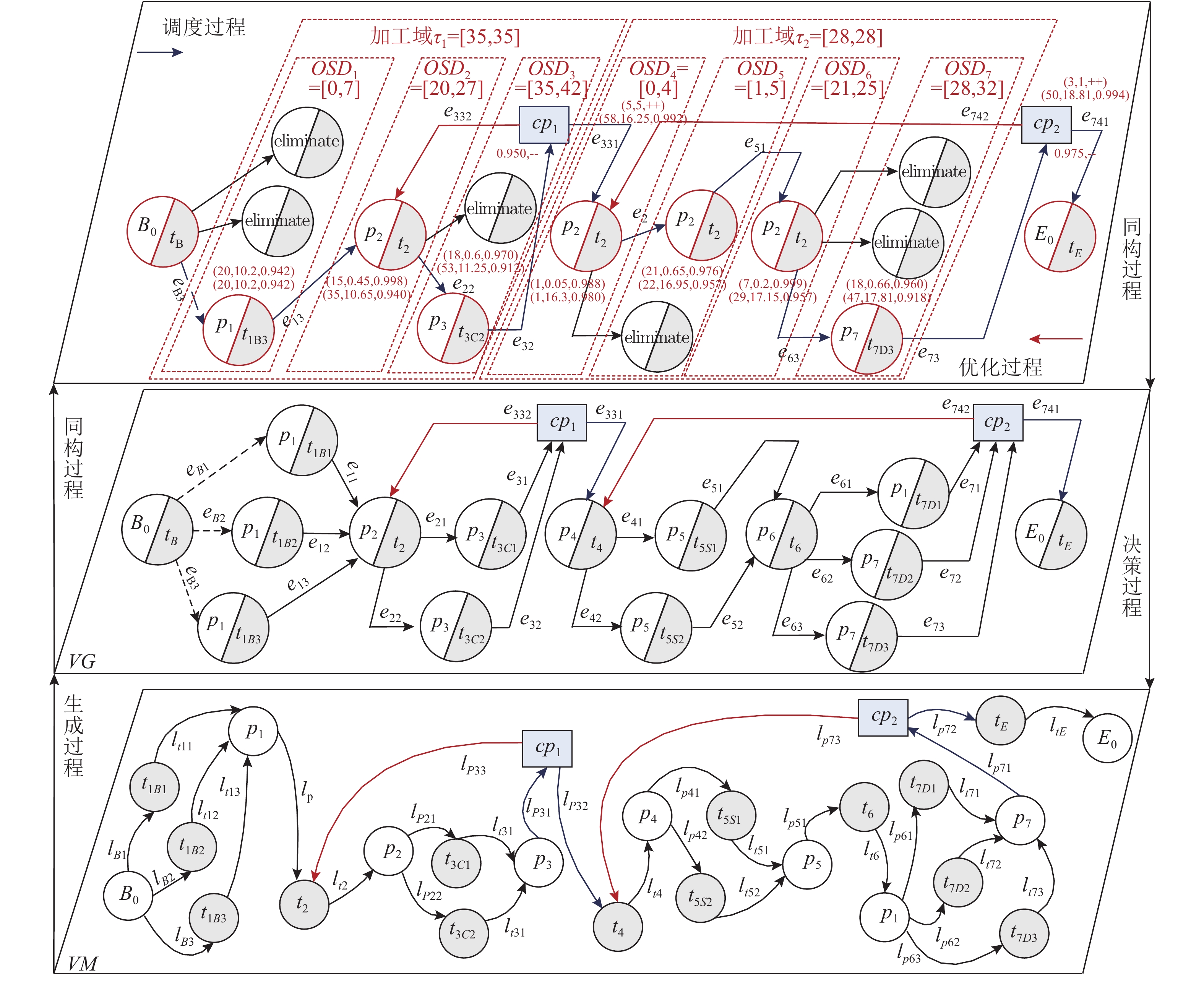

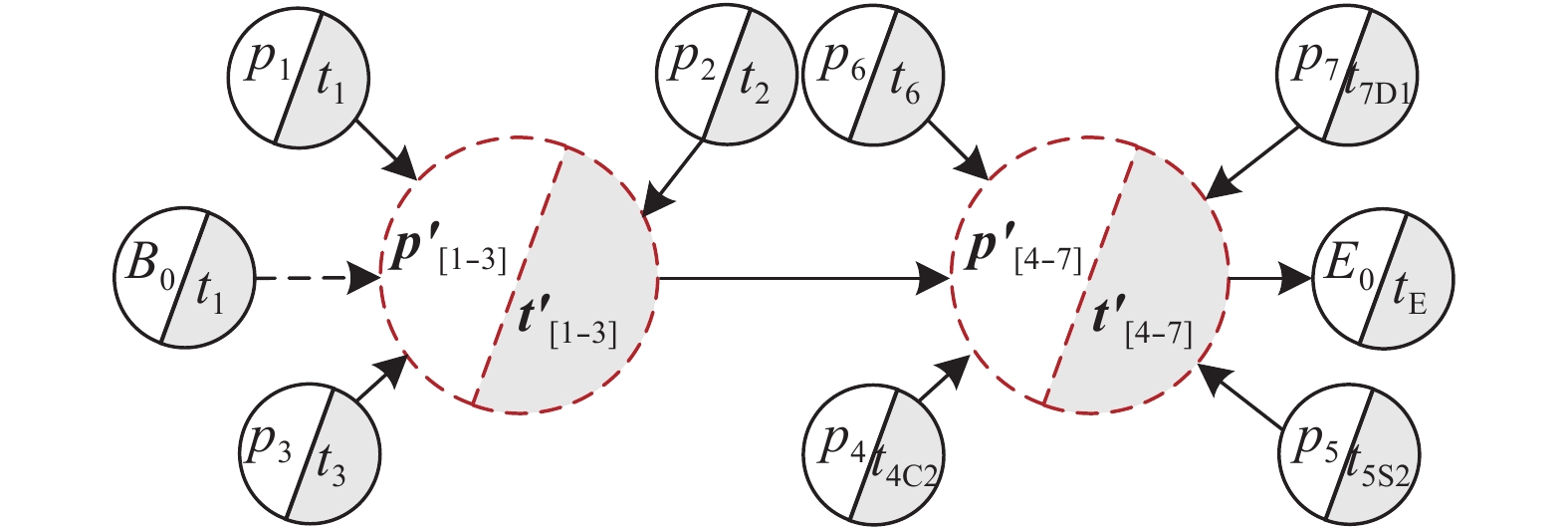

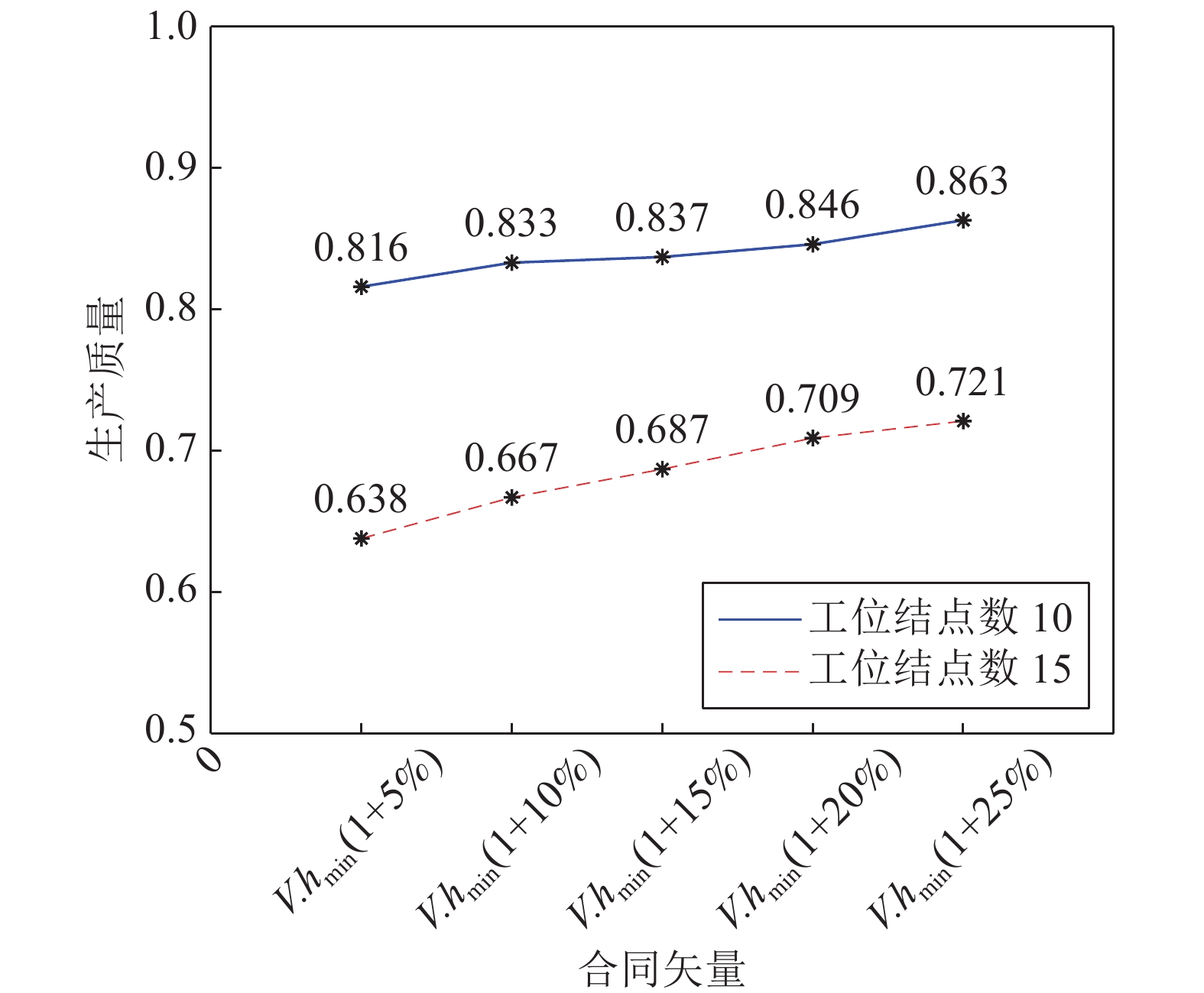

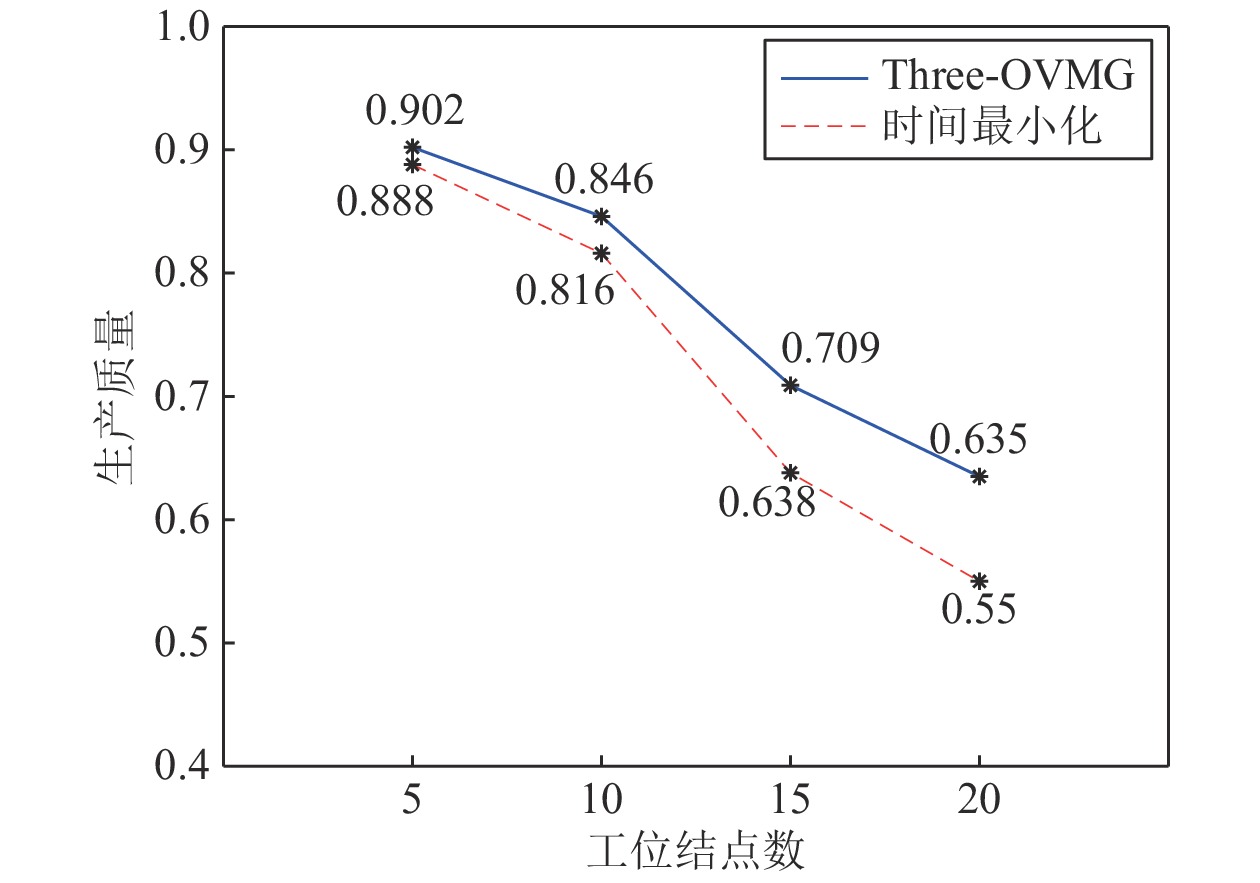

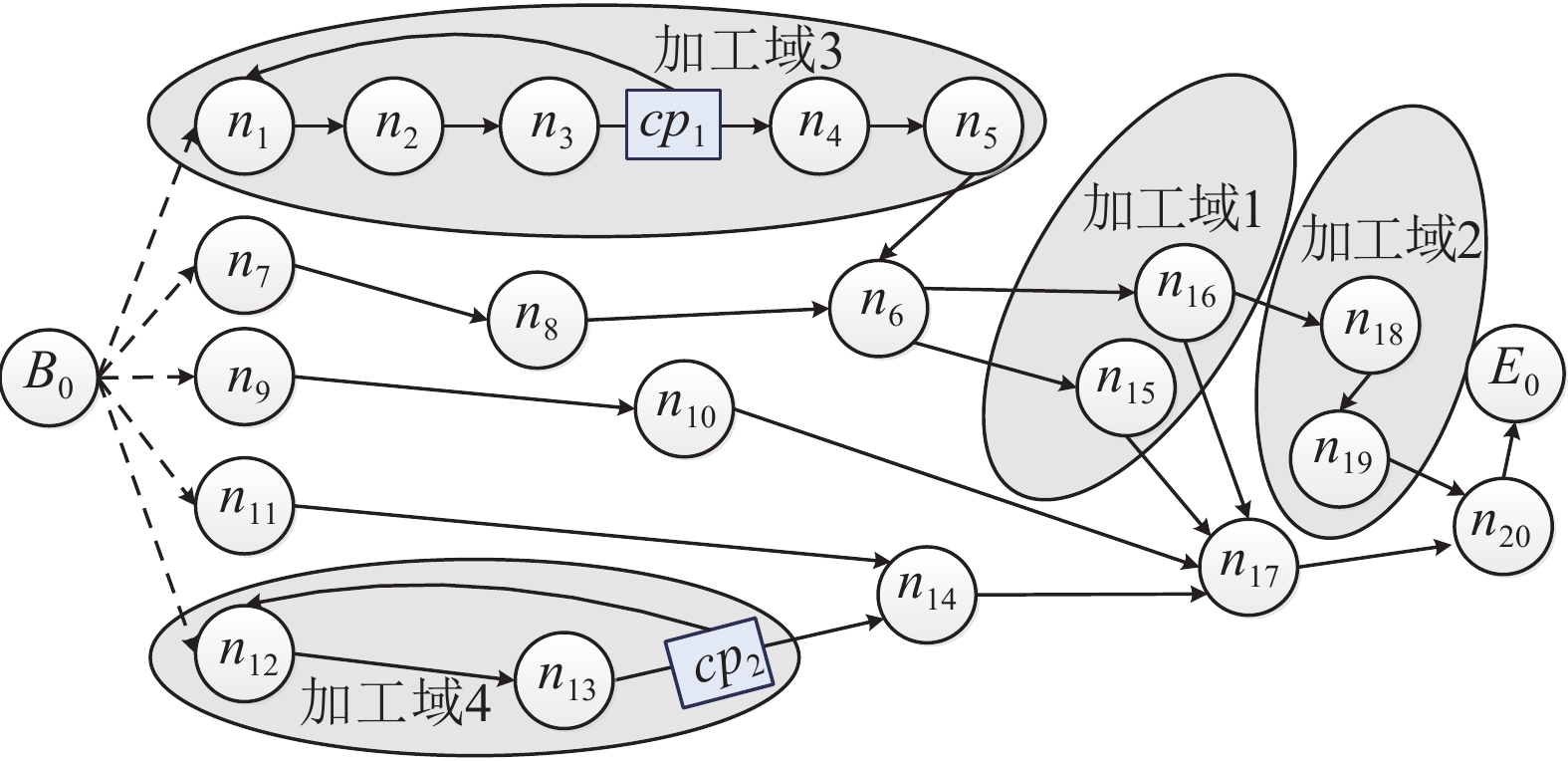

摘要: 时间、生产质量和成本是加工制造中相互制约的重要参数, 平衡此参数使制造工艺最优是一个NP (Non-deterministic polynomial)难题, 对此出现了许多优秀的调度方法. 然而这些方法的优化对象均为线性工艺, 对于普遍存在的非线性工艺却无法调度优化. 针对此不足, 本文以非线性工艺为优化对象提出了三层虚拟工作流模型Three-VMG (Three-virtual model graph)及其优化算法Three-OVMG (Three-optimal virtual model graph). 该模型和算法首先建立非线性工作流, 采用虚拟技术寻找虚拟结点进行重构, 将其改造为虚拟线性工作流; 其次结合工艺特点对模型进行分段, 采用逆向分层串归约来实现段内最优解, 采用累积最优解来衔接各段间的值; 最后根据优化结果自顶向下完成各层资源的优化调度. 实验表明, 该过程较传统时间最小化优化调度算法具有显著的优化效果, 其性能及可操作性也能满足工程要求.Abstract: Time, production quality and cost are important parameters of mutual constraints in manufacturing. Balancing these parameters to make the manufacturing process more reasonable is an NP (non-deterministic polynomial) problem, and there are many excellent scheduling methods to solve this problem. However, the optimization objects of these methods are linear processes, so they can not be scheduled and optimized for the prevalent non-linear processes. To overcome the deficiency, a three-tier virtual workflow model, Three-VMG (three-virtual model graph), and its optimization algorithm, Three-OVMG (three-optimal virtual model graph), are proposed to optimize the non-linear processes in this paper. The model and algorithm first establish a non-linear workflow, using virtual technology to find virtual nodes for reconstruction, thus transforming it into virtual linear workflow. Secondly, according to the process characteristics, the model is segmented. Uses serial reduction strategy to calculate reverse hierarchical solution in each segment, and then cumulative values of solutions between segments. Finally, according to the optimization results, the optimal scheduling of resources at each level is top-down accomplished. Experiments show that the process has a significant optimization effect compared with the traditional time minimization optimal scheduling algorithms. In addition, the performance and operability of the algorithm can meet the engineering requirements.

-

Key words:

- Workflow /

- manufacturing process /

- optimize scheduling /

- virtual technology /

- production quality

-

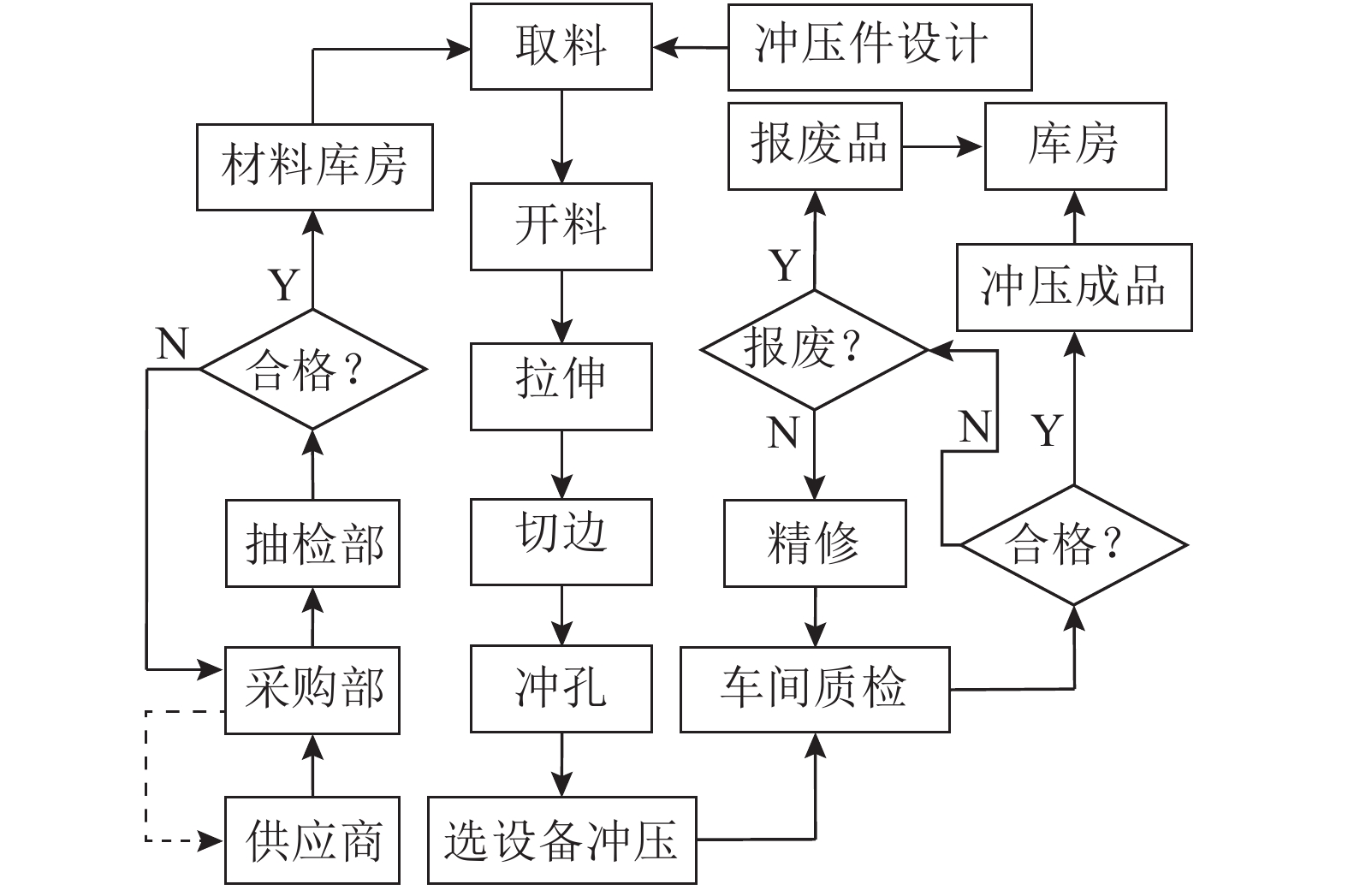

表 1 冲压工艺质量检测结点集合P和T

Table 1 Node set P and T of stamping process quality inspection

结点 含义 p1 供应商 p2 采购部 p3 采购部质检 p4 冲压加工 p5 零件抽检部 p6 精修部 p7 质检部 pE 仓库 t1 备料 t2 采购就绪 t3 采购部质检就绪 t4 待冲压 t5 抽检质量就绪 t6 精修就绪 t7 质检就绪 tE 待入库 表 2 各部门服务的时间、质量和费用

Table 2 Time, quality and cost of departmental services

编号 时间 (天) 质量 (%) 费用 (万元) B1 30 95.1 10.5 B2 25 95.6 11.0 B3 20 94.2 10.2 C1 20 95.6 0.5 C2 18 97.0 0.6 S1 21 97.6 0.65 S2 20 96.8 0.63 D1 20 96.9 0.67 D2 19 96.7 0.65 D3 18 96.0 0.66 t2 15 99.8 0.45 t4 1 98.8 0.05 t6 7 99.9 0.2 tE 1 99.9 0.04 cp1 — 95.0 — cp2 — 97.5 — -

[1] 谢志强, 张晓欢, 辛宇, 杨静. 考虑后续工序的择时综合调度算法. 自动化学报, 2018, 44(02): 344-362Xie Zhi-Qiang, Zhang Xiao-Huan, Xin Yu, Yang Jing. Time-selective integrated scheduling algorithm considering posterior processes. Actaautomatica Sinica, 2018, 44(02): 344-362 [2] Duro R J, Mogas S L, Oxman N. Flow-based fabrication: an integrated computational workflow for design and digital additive manufacturing of multifunctional heterogeneously structured objects. CAD Computer Aided Design, 2015, 69(12): 143-145 [3] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931-1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Actaautomatica Sinica, 2018, 44(11): 1931-1943 [4] Arabnejad H, Barbosa J G. A budget constrained scheduling algorithm for workflow applications. Journal of Grid Computing, 2014, 12(4): 665-679 doi: 10.1007/s10723-014-9294-7 [5] Lv M, Wang G. Research on workflow-based modeling method of product manufacturing process. International Journal of Smart Home, 2014, 8(3): 97-106 doi: 10.14257/ijsh [6] Mollajafari M, Shahhoseini H S. A cost-optimized GA-based heuristic for scheduling time-constrained workflow applications in infrastructure clouds using an innovative feasibility-assured decoding mechanism. Journal of Information Science and Engineering, 2016, 32(6): 1541-1560 [7] Koch G K, Gallucci G O, Lee S J. Accuracy in the digital workflow: from data acquisition to the digitally milled cast. Journal of Prosthetic Dentistry, 2016, 115(6): 749-754 doi: 10.1016/j.prosdent.2015.12.004 [8] Kianpisheh S, Charkari N M, Kargahi M. Reliability-driven scheduling of time/cost-constrained grid workflows. Future Generation Computer Systems, 2016, 55: 1-16 doi: 10.1016/j.future.2015.07.014 [9] Chirkin A M, Belloum A S Z, Kovalchuk S V, Makkes M X, Melnik M A, Visheratin A A, et al.. Execution time estimation for workflow scheduling. Future Generation Computer System-The International Journal of Escience, 2017, 75(11): 376-387 [10] Roberts P A, Willoughby I R, Barnes N. Evaluation of a gravimetric-based technology-assisted workflow system on hazardous sterile product preparation. American Journal of Health-system Pharmacy: AJHP: Official Journal of the American Society of Health-System Pharmacists, 2018, 75(17): 1286-1292 doi: 10.2146/ajhp170564 [11] Lucas S A, Ribeiro R, Teixeira M. Modeling and control of flexible context-dependent manufacturing systems. Information Sciences, 2017, 421(12): 1-14 [12] Stender M E, Beghini L L, Sugar J D, Veilleux M G, Subia S R, Smith T R, et al.. A thermal-mechanical finite element workflow for directed energy deposition additive manufacturing process modeling. Additive Manufacturing, 2018, 21(5): 556-566 [13] 敬石开, 姜浩, 许文婷, 周竞涛. 考虑执行可靠性的云制造服务组合算法. 计算机辅助设计与图形学学报, 2014, 26(3): 392-400Jing Shi-kai, Jiang Hao, Xu Wen-Ting, Zhou Jing-Tao. Cloud manufacturing service composition considering execution reliability. Jorunal of Computer-Aided Design & Computer Graphics, 2014, 26(3): 392-400 [14] 张玺, 刘明周, 张铭鑫, 葛茂根. 基于改进模糊Petri网的制造车间重调度策略优化研究. 管理工程学报, 2017, 31(2): 216-221Zhang Xi, Liu Ming-zhou, Zhang Ming-xin, Ge Miao-Gen. Research on rescheduling strategy optimization in manufacturing shop based on improved fuzzy petri Net. Jonrnal of Industrial Engineering/Engineering Management, 2017, 31(2): 216-221 [15] 张萌, 李国喜. 基于区间的制造服务组合多目标优化方法. 计算机集成制造系统, 2017, 23(8): 1787-1796Zhang Meng, LI Guo-xi. Multi-objective optimization of manufacturing service composition with interval numbers. Computer Integrated Manufacturing Systems, 2017, 23(8): 1787-1796 [16] Luo Zhi-yong, Wang Peng, You Bo, Zhu Su-xia. Serial reduction optimization research of complex product workflow’s accuracy under the time constraint. Advances in Mechanical Engineering, 2016, 8(10): 1-9 [17] 罗智勇, 朱梓豪, 尤波, 刘嘉辉. 虚拟工作流约束的时间-精确率迭代归约优化算法. 电子与信息学报, 2018, 40(08): 2013-2019Luo Zhi-yong, Zhu Zi-hao, You Bo, Liu Jia-Hui. Virtual iterative reduction optimization algorithm of workflow’s time-accuracy. Journal of Electronics and Information Technology, 2018, 40(08): 2013-2019 [18] Woo J K, Dong K K, Seong H K. Cost adaptive VM management for scientific work-flow application in mobile cloud. Mobile Networks and Application, 2015, 20(3): 328-336 doi: 10.1007/s11036-015-0593-4 -

下载:

下载: