|

[1]

|

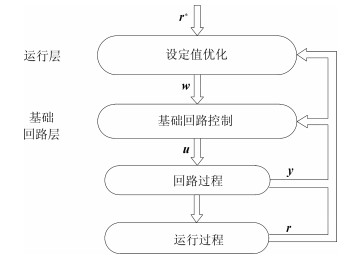

柴天佑.复杂工业过程运行优化与反馈控制.自动化学报, 2013, 39(11):1744-1757 http://www.aas.net.cn/CN/abstract/abstract18214.shtmlChai Tian-You. Operational optimization and feedback control for complex industrial processes. Acta Automatica Sinica, 2013, 39(11):1744-1757 http://www.aas.net.cn/CN/abstract/abstract18214.shtml

|

|

[2]

|

桂卫华, 阳春华.复杂有色冶金生产过程智能建模、控制与优化.北京:科学出版社, 2010Gui Wei-Hua, Yang Chun-Hua. Intelligent Modeling, Control And Optimization of Complex Nonferrous Metallurgical Process. Beijing:Science Press, 2010

|

|

[3]

|

柴天佑.工业过程控制系统研究现状与发展方向.中国科学:信息科学, 2016, 46:1003-1015 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgkx-fc201608005Chai Tian-You. Industrial process control systems:research status and development direction. Scientia Sinica Informationis, 2016, 46:1003-1015 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgkx-fc201608005

|

|

[4]

|

Skogestad S. Plantwide control:the search for the self-optimizing control structure. Journal of Process Control, 2000, 10(5):487-507 doi: 10.1016/S0959-1524(00)00023-8

|

|

[5]

|

Ye L J, Cao Y, Yuan X F, Song Z H. Retrofit self-optimizing control:a step forward toward real implementation. IEEE Transactions on Industrial Electronics, 2017, 64(6):4662-4670 doi: 10.1109/TIE.2017.2668991

|

|

[6]

|

Jaschke J, Skogestad S. NCO tracking and self-optimizing control in the context of real-time optimization. Journal of Process Control, 2011, 21:1047-1416 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f99a0156d4465b06373780e4860b85ca

|

|

[7]

|

Darbya M L, Nikolaoub M, Jonesc J, Nicholsond D. RTO:an overview and assessment of current practice. Journal of Process Control, 2011, 21(6):874-884 doi: 10.1016/j.jprocont.2011.03.009

|

|

[8]

|

Sequeira S E, Graells M, Puigjaner L. Real-time evolution for online optimization of continuous processes. Industrial and Engineering Chemistry Research, 2002, 41(7):1815-1825 doi: 10.1021/ie010464l

|

|

[9]

|

Sun Z J, Qin S J, Singhal A, Megan L. Control performance monitoring of LP-MPC cascade systems. In: Proceedings of the 2011 American Control Conference. San Francisco, USA: IEEE, 2011. 4422-4427

|

|

[10]

|

Souzaa G D, Odloaka D, Zaninb A C. Real time optimization (RTO) with model predictive control (MPC). Computers and Chemical Engineering, 2010, 34(12):1999-2006 doi: 10.1016/j.compchemeng.2010.07.001

|

|

[11]

|

Al-Shammari A A, Forbes J F. Post-optimality approach to prevent cycling in linear MPC target calculation. European Journal of Control, 2012, 18(6):558-569 doi: 10.3166/EJC.18.558-569

|

|

[12]

|

Pontes K V, Wolf I J, Embirucų M, Marquardt W. Dynamic real-time optimization of industrial polymerization processes with fast dynamics. Industrial and Engineering Chemistry Research, 2015, 54(47):11881-11893 doi: 10.1021/acs.iecr.5b00909

|

|

[13]

|

Ellis M, Christofides P D. Integrating dynamic economic optimization and model predictive control for optimal operation of nonlinear process systems. Control Engineering Practice, 2014, 22(22):242-251 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d5cab633219a01a66ce7e1ded2d1b270

|

|

[14]

|

Chai T Y, Zhao L, Qiu J B, Liu F Z, Fan J L. Integrated network-based model predictive control for setpoints compensation in industrial processes. IEEE Transactions on Industrial Informatics, 2012, 9(1):417-426 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0b3efc97111492c98ea4b6e285ad88d0

|

|

[15]

|

Zyl V F, Paquot F, Fouche F, Gomez A. Implementation of a SAG grinding expert system at Kansanshi Mine-Zambia. IFAC Proceedings Volumes, 2013, 46(16):178-181 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0214389137

|

|

[16]

|

乔俊飞, 韩改堂, 周红标.基于知识的污水生化处理过程智能优化方法.自动化学报, 2017, 43(6):1038-1046 http://www.aas.net.cn/CN/abstract/abstract19079.shtmlQiao Jun-Fei, Han Gai-Tang, Zhou Hong-Biao. Knowledge-based intelligent optimal control for wastewater biochemical treatment process. Acta Automatica Sinica, 2017, 43(6):1038-1046 http://www.aas.net.cn/CN/abstract/abstract19079.shtml

|

|

[17]

|

Li H X, Guan S P. Hybrid intelligent control strategy. Supervising a DCS-controlled batch process. IEEE Control Systems Magazine, 2001, 21(3):36-48 doi: 10.1109/37.924796

|

|

[18]

|

Xie S W, Xie Y F, Li F B, Yang C H, Gui W H. Optimal setting and control for iron removal process based on adaptive neural network soft-sensor. IEEE Transactions on Systems, Man, and Cybernetics:Systems, 2018, PP(99):1-13

|

|

[19]

|

Wang D, He H B, Liu D R. Adaptive critic nonlinear robust control:a survey. IEEE Transactions on Cybernetics, 2017, 47(10):3429-3451 doi: 10.1109/TCYB.2017.2712188

|

|

[20]

|

Lewis F L, Vrabie D. Reinforcement learning and adaptive dynamic programming for feedback control. IEEE circuits and systems magazine, 2009, 9(3):32-50 doi: 10.1109/MCAS.2009.933854

|

|

[21]

|

王鼎, 穆朝絮, 刘德荣.基于迭代神经动态规划的数据驱动非线性近似最优调节.自动化学报, 2017, 43(3):366-375 http://www.aas.net.cn/CN/abstract/abstract19015.shtmlWang Ding, Mu Chao-Xu, Liu De-Rong. Data-driven nonlinear near-optimal regulation based on iterative neural dynamic programming. Acta Automatica Sinica, 2017, 43(3):366-375 http://www.aas.net.cn/CN/abstract/abstract19015.shtml

|

|

[22]

|

代伟, 柴天佑.数据驱动的复杂磨矿过程运行优化控制方法.自动化学报, 2014, 40(9):2005-2014 http://www.aas.net.cn/CN/abstract/abstract18472.shtmlDai Wei, Chai Tian-You. Data-driven optimal operational control of complex grinding processes. Acta Automatica Sinica, 2014, 40(9):2005-2014 http://www.aas.net.cn/CN/abstract/abstract18472.shtml

|

|

[23]

|

Lu X L, Kiumarsi B, Chai T Y, Lewis F L. Data-driven optimal control of operational indices for a class of industrial processes. IET Control Theory and Applications, 2016, 10(12):1348-1356 doi: 10.1049/iet-cta.2015.0798

|

|

[24]

|

李金娜, 高溪泽, 柴天佑, 范家璐.数据驱动的工业过程运行优化控制.控制理论与应用, 2016, 33(12):1584-1592 doi: 10.7641/CTA.2016.60455Li Jin-Na, Gao Xi-Ze, Chai Tian-You, Fan Jia-Lu. Data-driven operational optimization control of industrial processes. Control Theory and Applications, 2016, 33(12):1584-1592 doi: 10.7641/CTA.2016.60455

|

|

[25]

|

Li J N, Kiumarsi B, Chai T Y, Fan J L. Off-policy reinforcement learning:optimal operational control for two-time-scale industrial processes. IEEE Transactions on Cybernetics, 2017, 47(12):4547-4558 doi: 10.1109/TCYB.2017.2761841

|

|

[26]

|

Kiumarsi B, Lewis F L, Modares H, Karimpour A, Naghibi M. Reinforcement Q-!learning for optimal tracking control of linear discrete-time systems with unknown dynamics. Automatica, 2014, 50(4):1167-1175 doi: 10.1016/j.automatica.2014.02.015

|

|

[27]

|

Lewis F L, Vrabie D, Vamvoudakis K G. Reinforcement learning and feedback control:using natural decision methods to design optimal adaptive controllers. IEEE Control Systems, 2012, 32(6):76-105 doi: 10.1109/MCS.2012.2214134

|

|

[28]

|

Wei Q L, Song R B, Sun Q F. Nonlinear neuro-optimal tracking control via stable iterative Q-learning algorithm. Neurocomputing, 2015, 168:520-528 doi: 10.1016/j.neucom.2015.05.075

|

|

[29]

|

Hewer G A. An iterative technique for the computation of steady state gains for the discrete optimal regulator. IEEE Transactions on Automation Control, 1971, 16(4):382-384 doi: 10.1109/TAC.1971.1099755

|

|

[30]

|

Bradtke S J, Ydstie B E, Barto A G. Adaptive linear quadratic control using policy iteration. In: Proceedings of the 1994 American Control Conference. Baltimore, USA: IEEE, 1994. 3475-3475

|

|

[31]

|

Chen X S, Yang J, Li S H, Li Q. Disturbance observer based multi-variable control of ball mill grinding circuits. Journal of Process Control, 2009, 19(7):1205-1213 doi: 10.1016/j.jprocont.2009.02.004

|

下载:

下载: